Accurately calculation of CO2 tax for waste incineration with 3D LiDAR

Since 1 January 2024, in Germany quantity-dependent CO2 emission charges have been incurred in thermal waste treatment, making accurate measurement of the quantities burned more critical than ever.

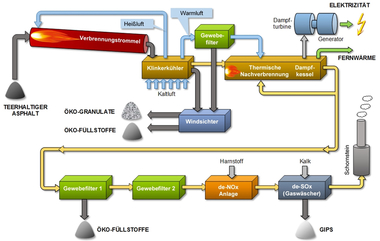

With the amendment of the German Fuel Emissions Trading Act (BEHG) effective January 1, 2024, thermal waste treatment became part of emissions trading, resulting in tangible costs for waste incinerators. According to Germany’s Supplementary Budget Law passed in December 2023, a fee of 45 €/t of emitted CO2 is now due, set to increase to 55 € by 2025. The fee is likely to be integrated into the European emissions trading system in 2027, with further increases anticipated.

To accurately calculate the amount of CO2 payments due, it is essential for incineration plants to measure the quantity of burned waste as precisely as possible. Overestimating the quantity leads to excessive payments, while underestimating it may result in legal sanctions such as fines, payments at increased rates, or even account suspension in the national emissions trading registry.

Issues with quantity measurement

Until now, many waste disposal companies had to rely on inaccurate methods for assessing waste inventory, such as visual estimation, counting of delivered truckloads, and periodic weighing, due to the lack of suitable technologies. However, even experienced staff often miscalculate the quantity. Counting or weighing provides an overview at the time of measurement but lacks readily available digital data. Consequently, between measurements, companies are unaware of their actual waste inventory. Thus, they cannot accurately determine how much they have incinerated and, as a result, the associated CO2 charges.

3D LiDAR technology for exact inventory data

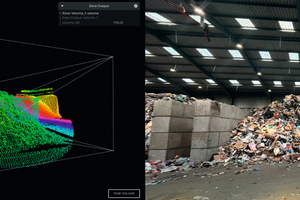

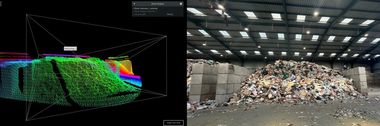

Blickfeld‘s 3D LiDAR solution captures the volume even of very large waste piles by precisely scanning their surface with laser pulses and calculating the inventory accurately using on-device software based on the results. The inventory information can automatically be transferred to digital waste management systems. Since measurements can be taken as often as needed, typically once or twice a day but also on demand or at a second‘s notice, waste disposal companies always know how much waste they are incinerating and, therefore, how high the CO2 levy must be set. With this data, they can demonstrate the accuracy of the levies to relevant authorities such as certification organizations and federal environmental agencies.

Further economic benefits

However, the advantages of real-time inventory data go beyond the precise calculation of CO2 levies. They enable more efficient and economical processes in waste disposition overall. Waste management companies can better assess their resources and optimize capacities. This helps not only with throughput planning but also enables the optimization of internal logistics processes across different locations. Moreover, accounting and logistics gain a reliable data source, reducing efforts to meet reporting obligations effectively.

Multiple benefits, easily accessible

With the extension of CO2 emission charges to thermal waste treatment, waste incineration companies have another significant reason to monitor their inventories precisely using LiDAR technology, alongside the overall improvement in efficiency. Blickfeld’s Smart LiDAR Qb2 offers particularly easy access to such valuable data, as it integrates software into the device for the first time. This eliminates the need for external computers for data analysis and transmission to material management software or the cloud. Since power and data run through the same line (Power-over-Ethernet), only few cables are required, simplifying installation and operation. Additionally, the Blickfeld solution features a robust housing with water and dust protection according to IP67 standards, making it particularly well-suited for use in demanding, harsh environments such as waste treatment plants.