ARJES and HWH with waste tire recycling on a large scale

Scrap tires are one of the most serious environmental burdens of our time. Every year, millions of worn or worn-out tires are replaced. But what happens afterwards? With no useful purpose, they are often dumped in landfills or illegal dumping sites, leading to significant environmental problems such as soil and water pollution.

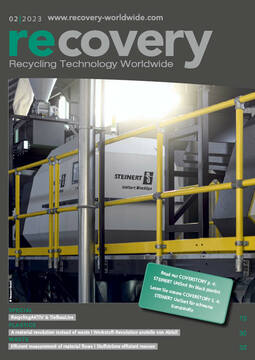

Recycling has a crucial role to play in addressing this issue. Through the use of innovative technologies, such as ARJES‘ twin-shaft shredders, not only car, truck, and tractor tires, but also massive EM tires can be processed in a way that is both environmentally and economically very beneficial.

At the RATL 2023 demonstration exhibition, ARJES will be working with HWH Machines to show what pre-shredding of truck and tractor tires looks like in practice. One of the first and decisive measures for further processing and recycling in the materials cycle.

With an exceptionally large field of view and strong performance, the Fuchs MHL320 is the first choice in industrial waste recycling. Double-edged cylindrical bearings on the complete loading equipment, a high-performance cooling system with spatially separated coolers and the double-row ball bearing slewing ring ensure special durability. Presented and demonstrated by sales partner HWH Machines, the handling machine is used to load scrap tires into the twin-shaft shredder.

That was the last journey that „those tires“ took – because now they are going through the shredder. A task that the stationary twin-shaft shredder ARJES TITAN 900 d-pu masters excellently. A large-volume receiving hopper ensures optimum feeding before it passes through the two shredding shafts, which run asynchronously and against each other. The resistant tire material, made of tough rubber and wire mesh, demands quite a bit of performance from the machine. At the RATL demonstration site, the TITAN 900 d-pu is powered by a 405 kW diesel engine that is certainly up to the task. Alternatively, the stationary shredder can also be operated with two 160 kW electric motors. In this case, the plant bears the designation „e-pu“. Both exhibits, electric and diesel versions, can be found in the exhibition area of RecyclingAKTIV by ARJES and HWH Machines.

In addition to the joint stand of ARJES and HWH Machines, the two sales partners Kurz Aufbereitungsanlagen and Moerschen Mobile Aufbereitung will also be present. Last year, they were already able to inspire the trade fair audience with an impressive live demo. This year, they will present the new products IMPAKTOR 250 evo II and EKOMAXX 800 from ARJES at their booth and demo areas.

Outdoor exhibition area, booth F254