Conserving resources for the future – processing waste qualitatively

Raw material and energy prices are continuously rising to dizzying heights. At the same time, conserving resources for the future and improving the quality of waste are key issues. Exactly here is where Binder+Co comes into play. The processing specialist from Austria is coming up with two new developments at IFAT 2022.

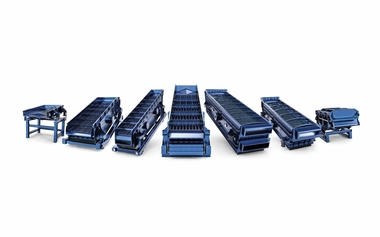

BIVITEC e+ big on effect, small in consumption

In the recycling industry, the BIVITEC flip-flow screen is a universally known and appreciated solution for screening difficult materials, as is frequently the case in the processing of recyclables. Binder+Co has now expanded its flip-flow screens to include an energy-saving variant.

This latest development is called BIVITEC e+ and is unbeatable in terms of investment and operating costs. The BIVITEC e+ combines two classics from Binder+Co: the low dynamic loads due to mass balancing of the resonance screening machine and the flip-flow system of the BIVITEC. This means: a lightweight design and thus significantly lower drive power.

As a result, the BIVITEC e+ can save up to 40 % in weight and up to 65 % in energy. The low dynamic loads of the latest Binder+Co flip-flow screen allow the dimensioning of a lighter substructure and thus a significant reduction in investment costs. This is also interesting for retrofits or machine replacements in existing plants, if the existing infrastructure needs not to be expanded or reinforced.

The BIVITEC e+ can be designed as a single-deck or multi-deck version and can be stacked as often as required. Another advantage is the adjustability of the vibration characteristics. Each screen deck can be individually adjusted and ensures that material difficult to screen is precisely classified. The applications of the BIVITEC e+ range from construction raw materials to the most diverse tasks in recycling, such as classification of wood chips, WEEE, car shredders, glass cullet, and compost. Since its successful launch on the market in 2020, the BIVITEC e+ has been recognized by customers around the globe as an innovative and, for many companies, indispensable tool for greater efficiency and sustainability. In a world where we all face resource and energy shortages, Binder+Co machines are an asset to all companies in the industry.

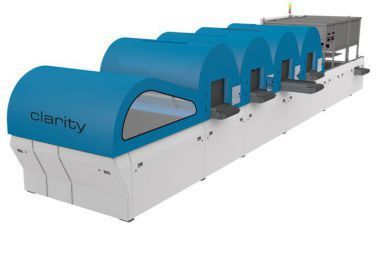

CLARITY LIBS – the maximum in aluminum

Aluminum is a material that is indispensable in everyday life. However, its production is highly stressful for the environment from several points of view. That is why the recycling of aluminum is particularly important. Provided it is well separated, aluminum hardly loses any of its quality and can be recycled an infinite number of times. In addition, far less energy is required to remelt recycled aluminum than to produce it from raw materials. Since aluminum to be recycled cannot be collected or separated by alloy type, it usually experiences „downcycling.“

In order for aluminum to be reused as a valuable material in the best possible way, it must be optimally sorted according to different aluminum alloys. Sorting technologies used to date quickly reach their limits, because aluminum alloys cannot be separated purely optically, which means that sorting systems operating purely on color differences cannot be used here. X-ray fluorescence and X-ray transmission systems can also only be used to a very limited extent, accepting compromises in the quality of the recyclate.

For this reason, Binder+Co has opted for LIBS technology in its proven CLARITY sorting systems. LIBS stands for Laser Induced Breakdown Spectroscopy and is an analytical method for determining the quantitative chemical composition of materials. In this process, a focused laser beam heats a small area on the material surface to a very high temperature. This creates a plasma consisting of electronically excited atoms and ions. When these atoms revert to their ground state, they emit light with characteristic wavelengths. These „fingerprints“ are unique to chemical elements and can therefore be used as sorting criteria.

This means that customers can now create high-quality and alloy grade-pure metal fractions and achieve far higher prices for them than for products that were previously only pre-sorted.

This LIBS technology is integrated into the automatic CLARITY systems with one or three detection tracks. Thanks to the compact design, existing plants can also be easily retrofitted with CLARITY LIBS systems. Binder+Co offers a safe process with its latest sorting series: The system is structurally designed to completely shield direct and indirect laser radiation.

Binder+Co‘s goal is to make recycling economical above all else. CLARITY LIBS not only creates new products for metal recyclers, but the operating costs of the sorting system also remain low thanks to the use of a very durable sensor.

Hall B5, Stand 215