In the beginning is the shredder

For use in plastic recycling plants, the demand for powerful shredders has grown. Especially those that can process entire bales at the beginning of the reprocessing chain. Modern washing plants in particular, such as produced by Herbold Meckesheim, require sophisticated shredder technology to be able to process high throughputs and challenging feed materials. At the same time, the machines should be largely wear-resistant and as simple as possible to operate and maintain.

Specifically the demanding processing of heavily contaminated plastics from the post-consumer sector requires adapted technological solutions. Shredders are requested that can mill large quantities of plastics with a high degree of contamination and various mineral impurities, for example. Integrated into modern washing plants, stage concepts are asked with technology adapted to the different process steps. The focus is furthermore on energy efficiency and correspondingly different motor and transmission concepts, in addition to classic drives with gears, above all belt drives or sometimes hydraulic drive systems.

Secondly, the attention rests on maximizing the longevity of the machines, even in heavy-duty operations. In other words, a high resistance to contaminants, a long service life of the cutting blades, and a pronounced robustness with regard to potential damage. This is taken into account by good accessibility to all machine parts, particularly the rotor, and easy replacement of wear parts, such as knives and plates. Efficient overload protection combined with short downtimes also meet today‘s requirements.

A good example of a modern solution in recycling lines is the single-shaft shredder 60/210 from Herbold Meckesheim, which handles high throughputs and entire bales of plastic and is suitable for both dry and wet size reduction. It combines a robust and durable construction with a maintenance-friendly design thanks to good accessibility through a large double-wing door and a hydraulically swing-away grinding chamber trough. In many washing plants, the EWS 60/210 serves as the first process stage.

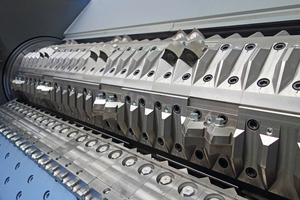

A special feature of the single-shaft shredder is the externally mounted and wear-protected rotor, which allows individual knife configurations in the cassettes and is equipped with screwed-on armor plates, making time-consuming hard facing obsolete. In opposite the rotor are also replaceable stator knives, and a second row can be fitted as an option. Thanks to its large flywheel masses, the double-sided belt drive is energy-efficient and requires little maintenance without a failure-prone gearbox. An overload clutch is used to protect against extraneous matters, which might cause damage to the machine.

Another example is the double-shaft shredder DWS 45/160 by Herbold Meckesheim. Due to a large contact surface of the rotor, the machine has a salient ingestion performance and is appropriate for materials that could only be fed in batches with traditional shredders, such as big-bags or large voluminous containers. The shredding of the material, whether in dry or wet operation, to a uniform and constant granular size is determined by the selection of the screen. Contrary to conventional twin-shaft shredders without screen, the DWS 45/160 does not produce long strips.

Refinement and enhancement of the concepts described, especially with regard to wear protection and ease of maintenance and the associated low personnel requirements, are current developments. In particular different rotor designs are of interest. In addition, a modular design and adaptation to flexible step configurations for washing lines determine the engineering work at Herbold Meckesheim.

Hall 9, stand B34