Increased system availability thanks to easy maintenance of the ripper blades

Maag Recycling AG in Winterthur/Switzerland, collects, sorts and reprocesses a wide variety of waste, including cardboard packaging, non-ferrous metals, scrap iron, glass and electrical and electronic equipment. For this purpose, alongside balers and sorting plants, the company operates a rotary shear, which has been used for shredding metals since 1999. Due to signs of wear and tear as well as the increasing demands on the entire recycling process, those responsible decided to replace the rotary shear. The wish is that, on the one hand, the new plant should have the lowest possible maintenance requirements and, on the other hand, be robust enough to handle even the shredding of massive parts without damage.

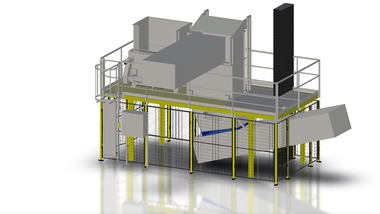

The company found what it was looking for at Erdwich Zerkleinerungs-Systeme GmbH from Igling in Bavaria: Their experts are using their experience to provide a weatherproof system based on the proven RM1350/2-2000 twin-shaft shredder, which can be optimally adapted to process various input fractions such as aluminium profiles, collected copper, zinc or cardboard tubes. Despite the limited space available on site, an additional ascending discharge conveyor, with an Fe separation system and a sorting line will be integrated, which will allow the work processes to be significantly optimised.

More than 50 % of Swiss municipal waste was recycled in 2017, according to an OECD study. Behind Slovenia, Germany, Austria, Belgium and the Netherlands, Switzerland is thus one of the frontrunners in waste recycling, well above the OECD average of just over 30 %.

Maag Recycling AG is also a factor in this high rate. As a regional waste management company in Winterthur, it accepts waste from both commercial and private customers. This waste is sorted and prepared in such a way that it can be readily further processed by other companies and returned to the material cycle. „In our company, sustainability and environmental protection play a central role in our corporate mission statement,“ explains Judith Maag, Managing Director of Maag Recycling AG. „For this reason, we strive to achieve the highest possible recycling rate for all materials.“

It is difficult to find spare parts for the

long-serving rotary shear

The company is pursuing this goal due to the increasing shortage of raw materials worldwide, especially of metals, which are experiencing a steady increase in value. In order to process the raw materials appropriately, the recycling company has had a rotary shear in use since 1999, which is operated in a primary treatment stage for shredding various input materials – mainly components made of aluminium, copper and zinc, but also books and cardboard. However, with the increasing age of the plant, the maintenance effort had increased and at the same time the search for spare parts became increasingly arduous. In addition, the rotary shear produces relatively coarse output fractions because the blades of the plant are not designed for the fine shredding that is now required.

„Based on the problem we were confronted with, a mechanical engineering company, with whom we work, recommended that we contact Erdwich for the new acquisition,“ reports Maag. The experts for shredding systems had already realized numerous plants with similar requirements, based on their many years of experience. „The twin-shaft shredder was designed in terms of size, drive power and shredding set in such a way that various input materials can be processed without complicated adaptations,“ explains Florian Böhm, Technical Manager at Erdwich. „Thanks to our experience, gained over many, we were able to design a plant that was a perfect fit for Maag´s requirements in a short space of time.“

Compared to the rotary shear, the new, frequency-controlled twin-shaft ripper, based on the RM1350/2-2000 model developed by Erdwich, no longer produces strips – instead, the input fractions are processed into a homogeneous output material thanks to 24 ripper blades. Depending on the material and the configuration of the cutter set, parts measuring 6 x 1 x 0.5 m can be shredded to a size of approximately 100 x 100 x 100 mm. To this end, control programmes can be stored or the machine can be freely programmed to adjust it for the different input materials. Another factor contributing to a high throughput rate is the radial feed press integrated into the hopper, which presses voluminous and light materials, which are difficult for the knives to grasp, against these shredding tools. These features result in a higher hourly throughput. Since the power of the plant, with 2 x 55 kW, is designed in accordance with great importance being placed on a considerable degree of robustness, even massive parts which can occasionally arise can be processed. This was impossible with the rotary shear. „If signs of wear and tear appear on the knives, they do not have to be replaced completely, but can simply be re-welded or re-sharpened by an in-house technician at Maag,“ explains Böhm. „This results in savings in costs and time, with only short downtimes and brings us more independence from suppliers.“

Limited space environment demands

adjustments to the system

However, the tight space conditions have proved to be a greater challenge – the new shredder was to be installed at the same location as the old rotary shear. The input material is fed into the ripper‘s hopper by means of an excavator with a polygrab meaning the RM1350/2-2000 can thus be conveniently remotely controlled from the grab‘s cab. After shredding, the material falls onto a vibrating conveyor chute directly below the plant. In addition to the ripper, a discharge belt with an ascending element and an overhead magnet are installed to separate the Fe fraction. This is followed by a sorting station with protective roofing.

Erdwich designed the plant and then carried out an extensive series of tests with original material obtained from Maag, in order to detect and eliminate any problems that might eventually arise, prior to the installation and commissioning of the plant. The entire shredding solution now has external dimensions of 9 x 7 x 4.4 m and is thus perfectly adapted to the limited space available at Maag. In addition, the commissioning had to be carried out very quickly and efficiently, as the site could only be closed for a very limited period of time. It had to be considered that the switching cabinets first needed to be converted for the new shredding solution. After delivery, the plant was completely assembled within just two days and successfully commissioned after a one-day test run.

Lower electricity consumption thanks to a higher energy efficiency class

Furthermore, Erdwich took into account the concept of sustainability, which plays a particularly important role for the recycling company. For this reason, the smallest possible drive motors with a particularly high energy efficiency class were used, which resulted in the power consumption during operation being reduced to an extremely low level. Those responsible at Maag are very satisfied with the progress of the project so far: „We can now run more material through the plant and also break it down better than before,“ explains Maag.

„For us, this means not only an increase in the quality of the output material, but also simpler processes – for example, when shredding aluminium profiles.“ Above all, the company found the technology provided to be very convincing, and ultimately, the advice and the service with which their special requirements were addressed. „Despite the complexity of the circumstances and throughout the entire project, there was a level of cooperation which was balanced, pleasant and from person to person. Should there be a need for a new plant at some future point, we will be open to a further cooperation,“ concludes Maag.