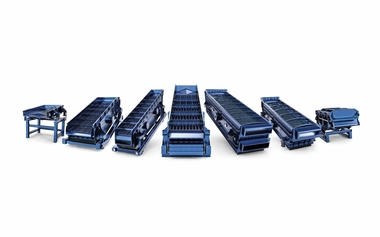

New 3D Compost Screen with quality guarantee for end customers

The moisture and long grain problems

finally solved

Christiaan Olde Bolhaar, managing partner of the compost specialist: „We have gained very extensive experience using mobile and stationary screening plants. We always had to struggle with two major problems: The strongly fluctuating moisture content of our raw material over the year and the associated long grain problems in the screened end product.“ Thus, the biomass specialist had to increase its separation cuts considerably in the wet season, which in turn led to harmful long grain parts. In the dry season, on the other hand, increasingly finer sieving was carried out to prevent long grain parts as far as possible. However, this inevitably led to the costly incorrect screening of the valuable organic material. Nevertheless, the passage of faulty long grain particels through the screening surface was not reliably prevented and continued throughout the year. A constant screening quality was therefore impossible.

Flip-Flow cassettes and 3D screening

panels decisive

This changed completely with the SPALECK 3D COMBI screening machine. „Even the first test in the SPALECK TestCenter was very promising. Subsequently we specified our exact requirements and tasks for SPALECK. We wanted to increase the screening quality to a maximum and make the best possible use of the valuable components of our raw material. After the second test we were absolutely convinced that we had found the right partner for our complex screening tasks.“

Frederik Stening, head of the SPALECK TestCenter: „The breakthrough in the joint development with Olde Bolhaar was our modular 3D COMBI screening technology which can be adapted to the screening material. This enables recyclers with difficult to screen materials, such as biomass processors, to produce a year-round constant screening quality that is optimised for the end customer.“

The 3D COMBI screening machine consists of an upper and a lower deck. For very moist material, Olde Bolhaar uses SPALECK Flip-Flow cassettes in the upper deck. These have an integrated Flip-Flow screening surface and can be easily installed by the user in the upper deck. Their purpose is the upstream screening of the fine fraction, so that in the further screening process moist, sticky and sometimes contaminating screening material is already screened on the upper deck. The downstream 3D screening panels of the upper deck then prevent faulty long grain particles from being shot into the lower deck. This means that long pieces such as horse mackerel, shrubbery, etc. are safely and completely removed via the upper deck. In summer, when the materials are sometimes very dry, the Flip-Flow cassettes can then be replaced by 3D screening panels from SPALECK. The lower deck is then used to screen the middle grain and the composter‘s valuable organic fines. Christiaan Olde Bolhaar: „The configuration of the lower deck is the same all year round. It enables us to screen the organic fines very reliably and consistently throughout the year, even with the most varied initial conditions of the material. For us, this is a significant simplification and increase in efficiency compared to our conventional screening machines.“

Win-win-win situation for the complete

recycling process

In particular the recycler‘s end customers, i.e. the substrate manufacturers and their private end customers, benefit from the screening performance of the SPALECK vibratory screening machine. Christiaan Olde Bolhaar: „With the new 3D COMBI Compost Screen we are able to guarantee our customer an excellent soil with high organic content all year round. This benefits the hobby soil users, but especially the professional buyers, the greenhouses and soil producers. Compared to that time, all our products are now almost completely free of long grain impurities. This enables us to significantly increase our quality level compared to our competitors in the market.“ As a result, the company was able to significantly upgrade its compost products and develop new sales opportunities. Frederik Stening, contact person at SPALECK: „For us it is important that our customers can flexibly adapt their SPALECK screening machine to changing feed materials. This is the only way to guarantee that they can reliably deliver the separation cut qualities required by the end customer.“