Phosphorus recycling from catalysts in the chemical industry

Researchers at TU Bergakademie Freiberg have developed a new process for recycling phosphorus from catalysts used in the chemical industry. The recycled phosphorus can be used as fertilizer or in new catalysts. The now patented technology thus conserves mineral resources as the only natural source of phosphorus.

Many chemical products are created through the use of catalysts that accelerate a specific reaction while remaining themselves. One example is the alkylation of benzene with propylene with the subsequent reaction to form phenol – a basic chemical used in the production of plastics, automotive parts, paints or coatings. Worldwide, more than 11 million tons of phenol are produced annually (source: L. Fernández, Global phenol market volume 2015-2026, AgileIntel Research, ChemIntel360, 2021 // www.stastista.com). "Silica-based pellets impregnated with phosphoric acid are used as catalyst. During production, the catalysts wear out and carbon is deposited on the surface of the pellets. This drastically reduces their catalytic activity. After about a year, the catalysts are disposed of,“ explains Dr. Peter Fröhlich.

"The phosphoric acid bound in the catalyst, with a proportion of between 10 and 20 %, cannot be used further and has so far been lost to the recyclable material cycle,“ he continues. The team led by Dr. Peter Fröhlich at the Institute of Technical Chemistry at TU Bergakademie Freiberg has now developed and patented a novel process for recovering phosphoric acid (patent number: DE 10 2017 207 457).

Dissolving phosphoric acid

from catalyst material

To do this, the researchers first heat the pellets impregnated with the phosphoric acid in a furnace to about 500°C to remove the organic impurities. Then the phosphorus itself is removed. "The new process is multi-step. First, the soot deposits are burned off and the residue is subsequently treated with water or a mineral acid,“ explains co-inventor and institute director Prof. Martin Bertau.

The raw phosphoric acid obtained is purified and then used to produce mineral phosphorus fertilizers. It can also be used again for catalyst production. "The new process contributes proportionately to the conservation of natural phosphorus resources and is an example of how valuable materials can be recovered from industrial waste,“ explains Prof. Martin Bertau.

Background: Recycling of chemical catalysts and sustainable phosphorus management urgently needed

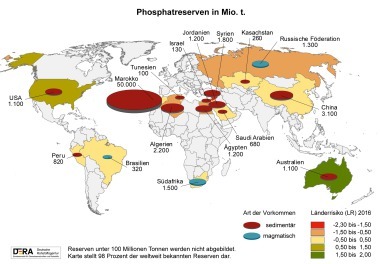

The process is used to recycle used catalyst materials and recover phosphorus. In nature, phosphorus occurs in the form of phosphates, for example in the mineral apatite. Currently, phosphorus cannot be replaced in fertilizers, which is why methods for recovering phosphorus are considered to have high potential for the raw material turnaround. The most advanced approach to recycling phosphorus is recovery from wastewater and sewage sludge, for which the TU Bergakademie Freiberg has already developed its own process (https://tu-freiberg.de/presse/parforce-der-tu-freiberg-kann-1000-kilogramm-phosphorabfaelle-pro-tag-aufarbeiten). "The approach now presented shows a promising alternative, as it conserves landfill space and uses phosphorus as a valuable material that is returned to the economic cycle. With a global volume of around 7500 t of spent catalyst, the new process could recover up to 1500 t of phosphoric acid. According to Statista, a total of around 40 million tons of phosphorus-containing fertilizers are produced worldwide every year,“ says Prof. Martin Bertau.