A reliable and safe baler

„TENAX specializes in high-end plastics and services that create customer and corporate value“ is the company’s mission statement and vision. TENAX is an International Group and Global Supplier with two manufacturing sites in the US (Maryland & Alabama), a distribution centre in California and 280 employees worldwide. For over 60 years, TENAX has provided specialty products for netting and fencing, pipe protection, construction, agricultural, gardening and DIY applications.

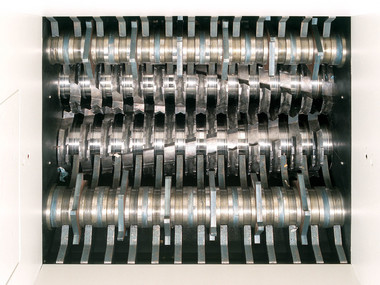

TENAX was looking for a reliable and efficient baler to dispose of extruded fence nets and grids. The new baler would replace their highly inefficient baler which was prone to failures and had expensive repairs looming. They turned to the US subsidiary of the German manufacturer HSM GmbH + Co. KG for the solution to their problem.

Established in 1960 in Italy, TENAX has seen steady production growth and continued success in many markets. Today, with production facilities in the US and three divisions (civil engineering, industry and retail), TENAX is a pioneer in the “Made in USA” movement and gained worldwide fame with its first US-produced product – orange safety fencing for building and construction sites.

Per week, TENAX has to dispose of about 10-12 bales, each weighing approximately 300 kg. Up to now, the bales were loose, messy and cumbersome, making disposal a big problem. Using an old, unreliable and unsafe baler, TENAX knew they needed a better solution to streamline their operation in Maryland. After looking on the internet, TENAX found HSM as a local vendor for their baling needs. HSM was quick to respond to TENAX‘s inquiry and was able to provide a test baler so that the company could make their own decision on the quality and engineering of the HSM machine.

The HSM V-Press 860 plus B baler is a safer machine than their previous machine, due to the door which slides from the bottom to the top. This allows the operator to push the materials safely into the machine and a forklift is no longer required to load it. The baler is reliable, which results in lower maintenance costs. The price was also on budget and so TENAX was able to make a quick decision and place an order.

With the HSM V-Press 860 plus B baler, TENAX has now optimized its disposal of waste materials, and can sell the bales to scrap vendors. The baler has an ergonomic design with a lower feeding height. The bales are denser, making it easier to double stack them, and TENAX therefore has more working space in its warehouse location. The base of the bales does not fall apart, making for a cleaner working space. Spending less on maintenance, this global supplier can continue to grow and be assured it is disposing of all materials efficiently and safely, confident in the reliability of an HSM baler.