Bonfiglioli‘s commitment to the 3 Rs

Bonfiglioli is ready to take on future challenges by presenting its wide range of innovative solutions for recycling processes and machines, as well as for biogas production and water treatment at IFAT 2024, the international trade fair for water, wastewater and raw materials management.

Bonfiglioli‘s commitment to the 3 Rs: Reduce, Reuse & Recycle

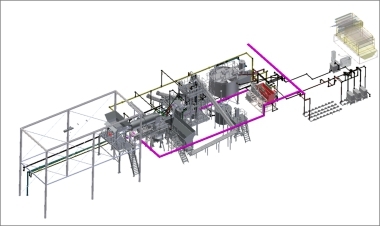

To ensure high quality and best results in the recycling process, Bonfiglioli designs and produces customized solutions for light and heavy duty applications for collecting, shredding and sorting waste materials. These solutions are developed with the highest level of customization.

Waste treatment applications offered by Bonfiglioli

Waste treatment applications offered by Bonfiglioli

© Bonfiglioli

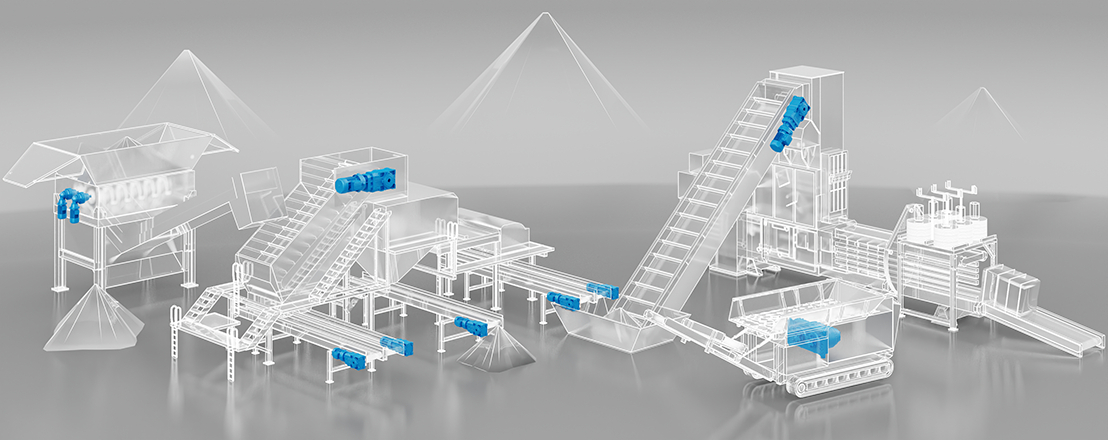

For light-duty applications such as Reverse Vending Machines (RVMs) and stand-alone shredders, Bonfiglioli offers solutions that are appreciated for their high reliability and long service life. For RVMs, the company provides a comprehensive package solution comprising the EVOX CP coaxial gearbox, marked by its smooth surface and compatibility with industry standards, the internationally certified MXN asynchronous low-voltage e-motor – available in the IE3 Premium efficiency class – known for its modularity, reliability and energy efficiency and the extremely versatile AxiaVert smart inverter. The latter is characterized by the availability of functional safety variants and the wide range of applications, including for the IoT. The second solution for back-naming machines included a worm gearbox from the W series in efficiency class IE3 and the asynchronous compact motor from the M Series, both CUS and CCC certified.

As far as stand-alone shredders are concerned, Bonfiglioli presented a 300 Series planetary gearbox. Characterized by an extra compact design and high shock resistance, the product is equipped with a BX series three-phase asynchronous motor, which ensures lower operating costs, energy savings and control flexibility, and the premium ACU (Active Cube) frequency inverter. Specifically designed for industrial automation, it has several advanced features, including Cyclic Synchronous Positioning mode, brake control and encoder evaluation. In addition, the new single axis for controlling servo motors, induction motors and synchronous reluctance motors offers high dynamics, performance and application flexibility. Active Cube is available with different communication protocols for enhanced connectivity with the most advanced control technology.

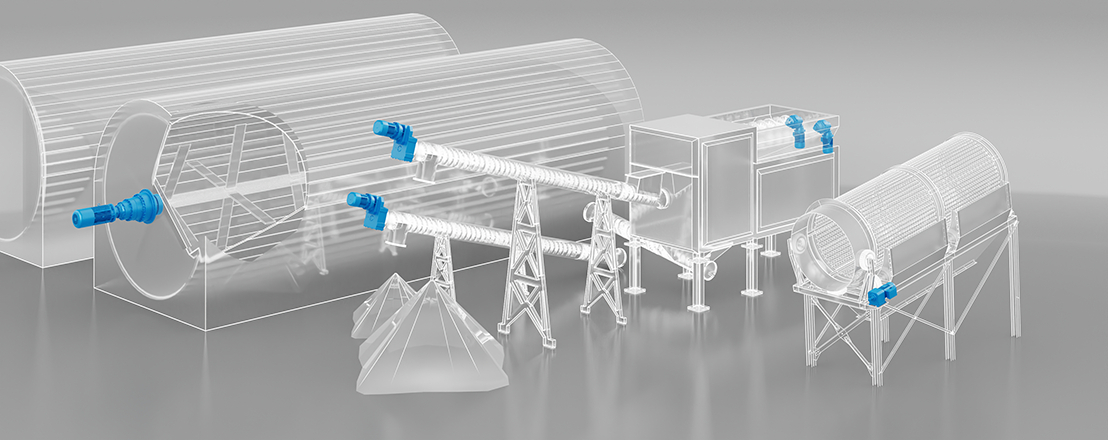

Recycling applications offered by Bonfiglioli

Recycling applications offered by Bonfiglioli

© Bonfiglioli

For heavy duty applications, Bonfiglioli has provided two solutions specifically designed for recycling plants and, in particular, for pre-shredding and waste sorting machines.

For primary shredding, the R3 Series was exhibited at the fair: Double planetary gearboxes with key features ranging from a peak torque of 80 000 to 129 000 Nm and gear ratios from 92 to 115. Equipped with sensors that measure performance, consumption and machine cycle times, the range offers services such as condition monitoring and predictive maintenance through the IoT Platform. Key elements of the platform include the functional portal, which simplifies the monitoring and reporting of the component‘s operating status by sending alarm and warning signals. The portal informs the planning of maintenance based on remaining service life by monitoring usage, uptime and performance. The alarm function, on the other hand, notifies maintenance modes and schedules.

For waste sorting machines, Bonfiglioli has developed a solution that combines a CP Series helical in-line gearbox with the MXN asynchronous electric motor and a decentralized DGM inverter. This has an optional brake rectifier module, automatic starting torque optimization and sensorless vector control.

Bonfiglioli supports biogas

Bonfiglioli is firmly committed to the transition to sustainable energy sources. In this sense, biogas represents a rapidly growing sector in which Bonfiglioli‘s products and maintenance services create added value. In this context, the Group offers geared motors for machines designed for mixing materials at variable power and speed ratios, for threshing and transporting solid and granular materials. Their reliability and durability are already appreciated by numerous German companies that use them in their agitators. The solution exhibited at IFAT consisted of a helical bevel gear unit from the HDO Series, which is designed for biomixers and agitators. ATEX certified, the gearbox is characterized by excellent shock resistance. Available with the output shaft in parallel (HDP) or right-angle (HDO) design, the HD series is suitable for operation in the harshest environmental conditions as well as in potentially explosive atmospheres, guaranteeing lower maintenance costs and long time service intervals.

Effective and compact solutions for water treatment

From desalination to purification, the water and wastewater treatment sector is complex and requires solutions that ensure uninterrupted operations. Bonfiglioli offers a wide range of products for automation. Effective solutions for various applications to support wastewater treatment plants where factors such as ease of maintenance, adaptability, compactness and high torque are crucial. Precise control over drive speed, water flow and pressure is crucial in energy-saving solutions for pumps, conveyors and filters used in wastewater treatment. A helical parallel shaft gearbox from the HDP Series – shown here for an aerator – was exhibited at IFAT 2024. Customizable, this gearbox is also IoT-capable and equipped with the Condition Monitoring Service. Bonfiglioli‘s products and solutions are designed to meet the most demanding requirements of aerator, agitator and mixer applications. That is, all devices that introduce air or other gases into liquids to facilitate oxygenation or other chemical reactions. Bonfiglioli products are able to withstand high radial loads, ensure mechanical separation between the lubrication chamber and the output, effectively control speed and are ideal for operation in aggressive environments. Optional solutions for remote monitoring and preventive maintenance are also available to guarantee perfect compliance with the requirements of primary applications.