Braskem, Kautex Maschinenbau and Erema will

demonstrate a closed plastic loop

Kautex Maschinenbau, belongs to the world‘s leading manufacturers of extrusion blow moulding machines. Their customers include major automobile manufacturers and suppliers, as well as companies working in the packaging industry. Their machines process thermoplastics which are completely recyclable. Kautex’s efforts towards contributing to the success of the Circular Economy comes from the company’s understanding of their responsibility to promote the recycling of plastics, and to work with partners to optimize material cycles. The further development of the use of recycled materials plays an important role for the company. „We regard the promotion of plastics recycling and working with our partners to optimize material cycles as an important responsibility of our company“, explains Managing Partner Andreas Lichtenauer.

Kautex Maschinenbau decided to process the Braskem material solution due to a better processability, less odour development and because they could offer their PCR and renewable material in a more sustainable way than conventional solutions, which is in line with their Circular Economy commitment. The raw material which is used for the demo bottles is derived from sugarcane, and the PCR material comes from already recycled material. By using Braskem’s technology, Kautex will significantly reduce the carbon footprint of those bottles as well as the use of fossil resources. For every kg of I’m green™ Polyethylene used more than 5 kg of CO2 is saved. In addition, the material usage is reduced by the use of foam technology and thus an additional optimization of the CO2 footprint is achieved.

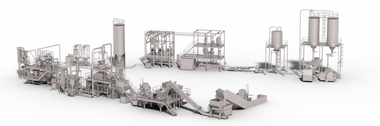

By joining forces with Erema, who will also be present at K 2019, the loop will be fully closed as they will showcase solutions for every single step within the plastics recycling process. This includes recycling technologies as well as software tools, and engineering and integration services for plastics recycling projects. Kautex’s bottles made of Braskem’s material will be collected by Erema and fully recycled in order to avoid any waste; showcasing the true objective of the Circular Economy.

At the Erema Circonomic Centre (outdoor area between hall 11 and 15) very tangible lighthouse projects will be displayed. The name Circonomic Centre, a word composed of “circular” and “economics,” refers to integrating recycling know-how into the plastics value chain providing both, economic and ecological benefits.

Recycling will be demonstrated in several live-performances, processing different plastic input material. In total more than 30 tons will be recycled during K 2019, including HDPE-bottles produced by Kautex.

According to Kautex’s exhibition motto “Creating Change Together” the German blow moulding machine manufacturer will collaborate with Braskem, one of the leading producers of biopolymers in the world, who strives with “Passion for Transforming”. Erema, one of the global market leader in the development and production of plastics recycling machines, offers its customers not only technologies and components but also consulting, engineering and planning services, as well as the expertise and dedication of its employees. All of these are success factors contributing to the performance of the customers, which is why Erema Group appears at K 2019 under the motto “Seeds for your performance”.

Kautex Maschinenbau

Eight decades of providing its customers with innovative products and services have turned Kautex Maschinenbau into one of the world‘s leading companies in extrusion blow moulding technology. With customers that include major automobile manufacturers and suppliers, as well as companies working in the packaging industry. All of them have come to rely on the knowledge and experience of a brand that stands for both quality and reliability. In addition to its HQ in Bonn, a Customer Service Center in Berlin and regional offices in the USA, Russia, China, Italy, India, Mexico and Malaysia, Kautex Maschinenbau operates an extensive global network of service and distribution offices

Erema Group

The companies EREMA – with the two business units POWERFIL and KEYCYCLE – 3S, PURE LOOP, UMAC and PLASMAC are part of the Erema Group. In addition to subsidiaries in the USA, China and Russia, the group of companies operates a further 50 agencies on all five continents to provide a reliable network for implementing tailor-made plastic recycling solutions for customers all over the world. In total, around 550 people now work for the Austrian company group based in Ansfelden near Linz.

Braskem

With a human-oriented global vision of the future, Braskem strives every day to improve people’s lives by creating sustainable solutions with chemicals and plastics. Braskem is the largest producer of thermoplastic resins in the Americas and the leading producer of biopolymers in the world, creating more environmental-friendly, intelligent, and sustainable solutions through chemicals and plastics. Braskem exports to clients in approximately 100 countries and operates 41 industrial units, which are located in Brazil, the United States, Germany and Mexico, the latter in partnership with the Mexican company Idesa.

⇥

www.kautex-group.com⇥;Stand: Hall 14 / A 16

www.braskem.com⇥;Stand: Hall 6 / D27

www.erema.com⇥Stand: Hall 9 / C05