Business Unit Recycling covers the entire

plastics processing

Herbold Meckesheim is reporting an excellent order situation for PET and film washing systems towards the end of the current fiscal year. At the end of the US fiscal year, mind you, because since late summer of last year Herbold has belonged to the US group Hillenbrand Inc. Last October, a separate Recycling business unit was set up under the umbrella of the conglomerate with the machine construction company Coperion in order to cover the entire process chain of plastics processing. This gives the Meckesheim-based plant manufacturer an even stronger basis and more impetus for its steady growth.

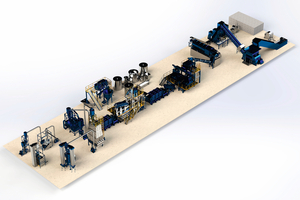

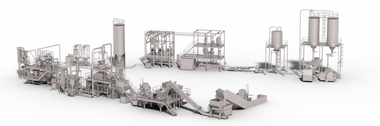

The Business Unit Recycling offers comprehensive and innovative total solutions based on the complementary and coordinated technologies of Herbold and Coperion. From mechanical processing – the shredding, washing, separating, drying and agglomerating of plastics – to the handling of bulk materials, dosing and extrusion as well as compounding and pelletising, the business unit covers the entire process and thus value chain. A worldwide network of engineering locations, for project management and service, ensures that orders are processed quickly, whether in the USA or Asia, and, thanks to short distances in the literal sense of the word, permits installations and commissioning as well as competent and fast on-site service. State-of-the-art test centres for product development and customer trials round off the recycling unit‘s range of services.

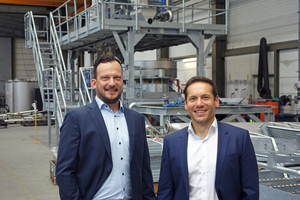

In the course of the integration, the management of Herbold Meckesheim was also restructured: In addition to Massimo Serapioni, who is also Head of the Business Unit, Christian Raiser took over the management of the operative business as Managing Director in July this year. He is responsible for the success of the site and reports directly to Markus Parzer, President Polymer Division of Coperion.

Christian Raiser learned how to manage a mechanical engineering company from scratch: his career began in 2007 in Coperion‘s production in Stuttgart in the screw element manufacturing segment; from 2013 onwards he was responsible for assembly and logistics in the then Compounding and Extrusion Division. In 2019, Raiser moved to Coperion‘s Wytheville site in the US state of Virginia, home to parts manufacturing and assembly of ZSK extruders for the American market, as General Manager and Vice President Operations.

Not only in the United States, where Herbold has a subsidiary, but especially here, the interest in the modular and automated recycling solutions from Meckesheim is unbroken. And PET washing lines continue to dominate the order intake alongside those for films. There is also strong demand for lines for big bags and hard plastics in general. In addition, the special machinery manufacturer is not forgetting those customers who are still interested in individual solutions. These are mainly granulators and fine mills as well as plastic compactors (for compaction). Herbold Meckesheim also traditionally thinks of the circular economy in terms of its own machines and maintains an extensive programme for retrofitting, overhauling and selling used units.

A look at the order books shows: it is always higher throughputs that customers around the world are striving for. In addition to the United States or the United Kingdom, the EU countries from Scandinavia to Bulgaria or Turkey and India in particular are strongly expanding markets. Often the enquiries here are now aimed at several parallel lines. The necessary mechanical processing of post-consumer material for subsequent chemical recycling on an industrial scale is also becoming increasingly important. Here Herbold also offers its own solutions for turnkey systems together with Coperion.

The Meckesheim-based company meets the increasing customer requirements through technical advancements in machine and plant design to increase throughput, durability, wear protection and ease of maintenance as well as the purity of the recyclates on the one hand. On the other hand, energy use, water consumption and personnel requirements are to be reduced as much as possible through efficiency and automation.

It is also clear that ever larger recycling lines are increasing the need for production space and manpower at Herbold Meckesheim. At present, 16 000 m² are available, divided between logistics, assembly and technical centre. Accordingly, Herbold is constantly looking for new employees and talents, whereby the integration into a large, global group of companies facilitates the recruitment of skilled workers. Herbold can also score points with its favourable location in the attractive Rhine-Neckar delta, flat hierarchies and a continuing family atmosphere among the 250 colleagues.