Compounding production requires specialized knowledge

Compounding production requires specialized knowledge

The Aurora experts first examine their raw material using spectral analysis in the laboratory in order to precisely ascertain its composition. Then they grind the plastic parts into small pieces. Some of the ground material is re-sold directly, but the bulk is processed into first-class composite following the addition of molten additives in a new extrusion process, from which new materials can be produced. „We have the expertise and experience to master this process,“ reports Alexander Schweinle. „In our laboratory, new recycled plastic formulations are constantly being developed for a wide variety of applications. We test them directly with our own injection moulding machine.“

Increased production

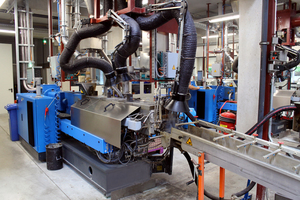

Alexander Schweinle is proud of his highly modernized compounding plant. „Our old building burned down in 2017, so we built a modernized, larger plant,“ says the production manager. „In February 2019, five extruders were put into operation instead of three. Completely expanded, the plant accommodates seven lines. We currently produce over 50 tons of compounds per day.“ Aurora expects demand to rise in the future. „I am certain that eventually there will be a legally mandated recycling quota,“ says Schweinle.

Investment in clean air

With the new factory, Aurora also invested in high-tech machinery. „Anyone familiar with the recycling of thermoplastics knows that it is a challenging and dusty business,“ says Schweinle. Visitors would be all the more surprised if they viewed the production at Aurora where Keller Lufttechnik extraction systems ensure clean air. The plant looks splendid. „Anyone who demands a clean operation in our industry should consider CLEACOM from Keller Lufttechnik,“ concludes Alexander Schweinle, who conducted extensive market research prior to his investment. CLEACOM stands for Clean Compounding. Keller Lufttechnik developed this separation concept specifically for plastics manufacturers. It combines dry separation, which is used for weighing and mixing raw materials, with a wet separation system for the extrusion process.

Dry separator for dosing scales

In association with the production manager at Aurora, Thomas Nägele, project manager at Keller Lufttechnik, adapted the CLEACOM technology to the specific requirements at Aurora. He says: “Where aggregates are weighed and added at the dosing scales, dusts are created, some of which are highly reactive and explosive. We have equipped our VARIO dry separator, to which all five lines are connected, with the constructive explosion protection ‚ProVent‘, a system for flameless pressure relief inside buildings.” The extraction system is already designed for any future expansion. An integrated frequency inverter automatically adjusts the performance of the dust extractor according to demand, thereby reducing power consumption. If further dosing stations are added, the experts will merely supplement some collection units.

Once the filter elements in the central system are contaminated with dust and a certain differential pressure is reached, a compressed air pulse ensures automatic cleaning. A filter change is only due after 15 000 to 20 000 operating hours. „If necessary, we merely change the big bags which collect the dust,“ says Alexander Schweinle. Keller technicians inspect the system once a year.

Wet separator for extrusion processes

The more challenging task is assumed by the VDN-TA wet separator, which ensures breathable air at the extruders. The extruders produce a homogeneous, molten plastic mass from the previously prepared formulation at high temperatures, which they press through fine openings. Long continuous plastic strands are formed, which are cooled with water and then broken into pellets. The material is dispersed using rotating screws before the finished granulate falls into a collection hopper. At the extruders, adhesive fumes as well as dust can escape. These emissions cannot be addressed by solely using dry separation. Alexander Schweinle confirms this: „The result of the dry separation in the old production facility was disastrous. The adhesive dusts coated each column of the separator, as well as in the extruder and inside the plant. Dust reformed soon after cleaning,“ he remembers. As a result of the wet separation process, the laborious cleaning task no longer plays a role today, and Aurora employees can devote more time to their core business and to quality control.

Water mist absorbs adhesive dusts

„In order to keep the ductwork clean, we saturate the adhesive particles with water as soon as they enter the ductwork system. We use the Venturi principle to create a fairly even mist,“ says Thomas Nägele. When the contaminated air finally enters the separator, it is doused there by another Venturi nozzle. Using centrifugal force, the system then separates the fine water mist loaded with foreign substances from the air stream. In large plants such as Aurora‘s, the water then flows into a huge holding tank where the impurities will settle. A sludge scraper clarifies the water, which can then be reused.

„Keller Lufttechnik referred us to its partner Hebro Chemie for the correct handling of the waste water. The company advised us on measures to prevent the growth of microorganisms and reliably bind the impurities. This makes the water that we recycle very clean,“ says Alexander Schweinle. „What remains is about one bulk container of sludge per month, which we hand over to a specialized waste disposal company.

Customized solutions for individual challenges

The fact that the new Aurora production plant is so clean is the result of beneficial cooperation between Aurora and Keller Lufttechnik. „We co-designed the system and determined customized solutions for some special challenges,“ confirms Alexander Schweinle. For example, there was a seal on the extruder, located on the coupling between the blower and the material feed screw. „Although we tightened the seal regularly, fine powder always escaped. Previously, our employees would address the problem directly. Additionally, the powdery residue caked onto the warm surface of the extruder,“ explains the plastics expert. „Now we’ve installed a collection system at this point that immediately removes the dust and works perfectly.”

„Everything is operating smoothly“

Aurora operates in three shifts for six days a week. To ensure that production does not experience a shutdown, Aurora relies on a functioning extraction system. „We conscientiously maintain the separators,“ says Alexander Schweinle. Saturday is designated for cleaning so that the process resumes smoothly again on Monday. The fan of the wet separator is equipped with a vibration sensor. This signals when the blower is not operating smoothly and if the fan impeller may either have to be cleaned or replaced soon. „Aurora thereby has adequate lead time to plan a shutdown for the exchange of spare parts that is compatible with the production schedule,“ explains Thomas Nägele.

Alexander Schweinle is very satisfied with his decision to install CLEACOM. „We primarily did this for our employees,“ he says. „However, I now see how the clean production at Aurora Kunststoffe also benefits our company‘s reputation with customers, suppliers and the general public“.