Efficient conveying with Wessjohann rope conveyors

In the context of sewage sludge treatment, the transport of the granulate after drying is a component that certainly deserves attention. Here, Wessjohann‘s rope conveyor system for bulk materials has already proven its worth in many places.

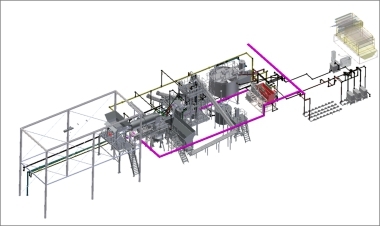

The reliable and well-engineered conveying technology, repeatedly used also in municipal sewage treatment plants, ensures that the sewage sludge granulate can be conveyed safely, efficiently and with low noise in a continuous process from product reception to the transport route to product discharge. The modular design of the system, which can be easily adapted to confined spaces, provides a special flexibility that can be regarded as a unique selling point. Added to this is the aspect of energy consumption during operation, which proves to be extremely low.

Expectations fulfilled

For the wastewater treatment plant operator, the conveyance of the dried sewage sludge, whether in the form of granules or powder, is only one stage of the treatment process. Nevertheless, at many sites there are confined spaces between the product intake from the dryer up to the product discharge at the collection point, often designed as bulk cone or container filling. This is where the rope conveying system shows its qualities, especially in the technology used by Wessjohann, which proves to be future-proof with continuous innovations. The conveying rope running in a pipe system with sprayed-on driver discs takes the bulk material along, driven by the patented friction wheel drive or claw wheel.

Due to the deflection corners adapted to the environment, the overall design proves to be very compact. Here, the conveying process, which is often permanent, deserves special attention in terms of operational reliability and operating results, as practical examples show. The local people were and are fully satisfied with the application in the municipal sewage treatment plant of the city of Soltau in Lower Saxony.

Dipl.-Ing. Karl-Hermann Ahrens, the former plant manager of the sewage treatment plant operated by the municipal sewage company of the city of Soltau, put it this way before his retirement: „The Wessjohann rope conveyor system for dried sewage sludge has already been in operation at our plant since 2019. The process runs permanently 24 hours a day, 7 days a week, so when we operate it over several weeks, we get about 6000 operating hours a year.“

Today, the current plant manager Dipl.-Ing. Michael Jerokowski adds to this example of conveying efficiency: „Thus, operating results, operational reliability, the almost maintenance-free function and the low energy consumption fully meet our requirements for an economical and efficient conveying system. Furthermore, the system runs almost noiselessly.“

Rope conveyor system, flexibly

adaptable to any space

In Soltau, too, the plant design shows its flexibility in the use of the available space. Here, the conveyor system running in a circle bridges approx. 65 m from the drying plant to the discharge point, so that the pipe construction runs as an endless system over a length of more than 130 m.

Another application example shows the use in Ostrava, Czech Republic, near the Polish border, where the conveying of sewage sludge granulate into collection containers takes place over 40 m, thus approx. 80 m pipe conveying distance.

The proven modules of the Wessjohann rope conveyor system are based on the metered forced guidance of the granulate at the receiving hopper, the low-noise friction wheel drive, the resistant driver discs and the self-cleaning corner rollers for deflecting the conveying run. Thus, with the rope conveying system of the Lower Saxony manufacturer, operators of sewage treatment plants have at their disposal a process for the dried sewage sludge that implements the conveying of sewage sludge granulate extremely effectively.

Hall 7, Booth T 48-7