Emissions-free conveying of alternative fuels in power plants in Asia

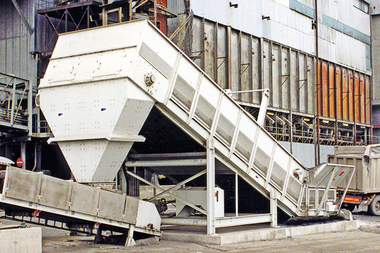

Installation on site of the Samson® Material Feeder

Installation on site of the Samson® Material Feeder © AUMUND To reduce climate-damaging CO2 pollution by fossil fuels, energy intensive industries such as power plants are starting to use more and more alternative fuels. AUMUND offers conveying solutions for handling and conveying alternative fuels all over the world. AUMUND Asia in Hong Kong is supplying specially designed Samson® Material Feeders to customers in Thailand and Japan. The machines are equipped with filters and enclosures so that the intake and onward feeding of fuels can be carried out cleanly.

One of AUMUND’s biggest Thai customers operates a plant in Saraburi, just north of Bangkok, where industrial and household waste is pre-treated and made into highly calorific alternative fuel. This lightweight material is tipped by trucks directly onto two Samson® Material Feeders type 800, with a capacity of 80 t/h each, to be conveyed onward to the thermal process. The Samson® Material Feeders guarantee not only efficiency but also a clean intake of the waste discharged by the trucks. This method avoids the trucks having to drive to the plant, reducing exhaust emissions.

An AUMUND customer in Japan has also decided to purchase two Samson® Material Feeders type 800. These each have a capacity of up to 70 t/h and will operate in a new biomass power plant in a port, where they will receive wood pellets and palm nut shells from front end loaders. The dust which would otherwise have been released into the environment by unloading and transporting the biomass from the storage hall to the boiler will be avoided, thanks to the filter and enclosure on the Samson® Material Feeder.