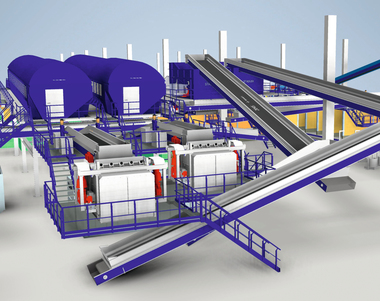

Entsorgungstechnik BAVARIA GmbH: Plant automation and optimization in the sorting of recyclable material

Process data are continuously recorded online at the point of input and at other measuring points. In addition, material parameters regarding the composition of the material are continuously captured online at the near-infrared machines integrated in the plant. The material stream is fully automatically monitored during the entire sorting process. The plant operator can thus react on changes in the input or in the process flow and apply corrections immediately. In practice, ROWE achieves a constant high output quality - irrespective of input fluctuations.

Through the use of a specially developed intermediate bunker, the usual fluctuations in the input material composition are compensated for and the mass flow will be homogenized. The downstream sorting units can thus work at highest efficiency at all times.

Another advantage process optimization provides is its high reliability of results. The plant can achieve constant results across all layers. Fluctuations and influencing parameters will become more transparent for the operator.

The MAX POS process optimization system can be installed or retrofitted as an optional tool for optimum plant control in a number of sorting plants.

The Entsorgungstechnik BAVARIA GmbH has been working in the field of recycling technology for more than 30 years and belongs to the leading specialists in the planning and construction of sorting plants for materials, such as waste paper, commercial waste, lightweight packaging, special solutions etc.

Forward-looking is also the new sorting robotor for light fractions. The Entsorgungstechnik BAVARIA GmbH also attaches great importance to competent service and reliable customer care.

Hall B5, Stand 411