First Terex Recycling Systems plant installed at Collard Group

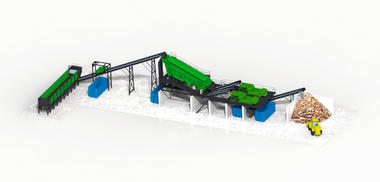

Collard Group, based in Reading/UK, has chosen a Terex Recycling Systems plant to increase the processing capacity of its site and recover cleaner products of higher value, whilst not adding to the manual labour requirements. Initially intended to be a plant upgrade, the Collard Group opted for a full plant installation after being pleased with the first phase of the install.

The plant, which is the first Terex Recycling Systems installation, was specifically tailored to suit Collard Group’s site and the material which would be fed into it. Together with their distributor Molson Green, Terex Recycling Systems developed a process which incorporated advanced mechanical separation that would increase Collard Group’s processing capacity and recover products of a higher purity than what was previously achieved. The team worked within restricted space and constraints of fitting the plant inside and around the existing building, all whilst planning the installation around Collard Group’s site works, that included the erection of a new building.

The Terex Recycling Systems plant increases Collard Group’s processing capacity

The Terex Recycling Systems plant increases Collard Group’s processing capacity

© Terex

The process starts with skip material being loaded into a Waste Feeder and conveyed to a Combi Screen, which separates into 4 size fractions using a combination of 3D and Flip-Flow screening (0 – 10 mm, 10 – 50 mm, 50 – 100 mm and +100 mm). Over-Band Magnets recover ferrous metals from 0 – 10 mm, 10 – 50 mm and 50 – 100 mm, and Air Separators remove light material from 10 – 50 mm and 50 – 100 mm. A Manual Quality Control Picking Station has operators working to remove any remaining contaminants from the 10 – 100 mm heavy fraction. Following this, an Eddy Current Separator recovers non-ferrous metal from the 10 – 100 mm heavy fraction. Another Manual Picking Station has operators recovering materials such as wood, card, and plastic from the +100 mm, and an Over-Band Magnet recovers ferrous metal. Finally, an Air Separator removes light material from the +100 mm.

The highly efficient plant is processing a mixture of Commercial and Industrial (C&I) and Construction and Demolition (C&D) waste

The highly efficient plant is processing a mixture of Commercial and Industrial (C&I) and Construction and Demolition (C&D) waste

© Terex

The outcome is a highly efficient plant that is processing skip waste – a mixture of Commercial and Industrial (C&I) and Construction and Demolition (C&D) waste – to produce 0 – 10 mm fines, ferrous metals, clean 10 – 100 mm heavy fraction (inert), non-ferrous metals, wood, plastic, paper & card, and clean +100 m heavy fraction (inert) materials.

Robert Collard, Managing Director, Collard Group said, “We are driven by a zero waste to landfill commitment, we take waste from site, and process it to make it useful again. We call this recycling the past for the future. To achieve this goal, it is important that we have the latest equipment that is optimised to meet our specifications. Terex Recycling Systems and Molson Green worked with us to ensure the design, delivery and installation of our new plant worked around our site operations, also taking into consideration our site preparation works to include foundations, building modifications and power supply. Close collaboration between all parties ensured our requirements in terms of output were met, whilst also keeping the plant footprint to a minimum to aid their site operations.”