GAIN retrofit for AUTOSORT systems

Increasing scarcity of resources and even larger flows of waste are leading to a more and more important role for the subject of recycling. The focus is on the quality of the recycled materials. Above all, the use of sorting technology is appropriate in many sectors in order to attain the purest materials flows possible.

Sorting systems in the field of waste recycling – and in the sorting of plastics, in particular – is a fascinating topic. Here, high-tech computer control is combined with physical analytical methods in order, for example, to permit the separation and recycling into products of equivalent quality of plastics of differing composition. There is now a new route to the obtainment of even purer sorted fractions and the optimisation of the sorting process.

TOMRA Systems ASA is one of the leading suppliers of both sensor-based sorting technologies for sorting and recycling facilities and of container-return systems. The company is based in the Norwegian town of Asker. Founded in 1972, around 82 000 return systems have now been installed in more than sixty markets, receiving more than 40 billion previously collected cans and bottles annually. Sorting solutions are in use in the food, recycling and mining sectors. The most diverse range of sorting systems, in each case tailored to the corresponding material, can be found in more than 100 markets in the recycling sector, with some 6500 units installed. „Rethinking how we obtain, use, reuse and optimise the world‘s resources is the right path at the right time. This is how the next revolution begins“ – Tomra derives its corporate philosophy from this perception: „TOMRA aims to be the leader in the resources revolution via the development of sensor-assisted solutions for assurance of optimum resources productivity. The provision of smart solutions for optimisation of our resources – procurement, use, management, recovery, recycling and reuse – is the key to the resources revolution.“

TOMRA has used artificial intelligence (AI) for a long time, but has, since last year, also gone a step further and is now offering a sorting machines that make use of the new method of AI called Deep Learning. In GAIN, TOMRA has introduced the first Deep Learning based sorting software, unveiled at the Ecomondo 2019. Available as an optional expansion module for AUTOSORT machines, GAIN technology is set to improve the productivity of sensor-assisted sorting machines even further. Based on classification of objects using sensor data and further processing using Deep Learning, GAIN now allows for sorting items, which were previously not separable, with high purity levels and without restricting the throughput rate of the AUTOSORT. As Philipp Knopp, Product Manager Recycling, explains: „The interlinking of our sorting technologies with Deep Learning makes our AUTOSORT machines even more efficient. GAIN technology will, in addition, contribute to adapting sorting systems to new waste streams – an important feature which will attain even more importance on the path of development towards the circular economy.“

One of the first applications for which GAIN technology has been trained is the detection of silicone cartridges in PE recycling flows. The silicone cartridges used in the private and industrial building sector continue to contain remnants of silicone even after they have been used, and so the cartridges – although they constist of PE – must be removed, in order not to cause problems during the subsequent extrusion process.

For this reason, the first version of the GAIN system marketed by TOMRA has been specially developed for the diversion of PE silicone cartridges out of the PE flow using camera data. The optical features of the objects which are to be separated in a sorting task are learned from thousands of images. For this purpose TOMRA uses the Deep Learning method mentioned above. Deep learning emulates the activity of a large number of neurone layers in the human brain in order to enable it to carry out complex tasks. During machine training GAIN learns how the artificial neurones are to be connected and weighted for the purpose of classifying objects. Deformed and incomplete cartridges are then also detected. Field tests with a two-stage process (i.e., two systems are used, one downstream the other) resulted in the extraction of 99 % of the cartridges.

recovery magazine had the opportunity of taking a closer look at the new system – Dr. Petra Strunk, Editor-in-Chief of recovery, spoke to Technical Manager Dr. rer. nat. Daniel Bender and Product Manager Philipp Knopp, on the application potentials for artificial intelligence in sorting machines.↓

recovery: What was the impulse for the development of GAIN and for the use of the Deep Learning methods?

Dr. Daniel Bender: In practically all recycling facilities, there are certain situations in which people perform the sorting work. Humans are more capable of solving certain tasks than our classical sorting machines, because they have an understanding of the objects to be sorted and – where these objects can be visually differentiated – are able to make a dependable decision as to whether an item needs to be diverted out or not. These are usually jobs which do not provide any particularly good working environment, however, they are very strenuous and can also, in some cases, be hazardous. Costs, speed and consistency are also criteria arguing in favour of a machine-based solution. that‘s where TOMRA wanted to start. In 2012, the results of international research demonstrated that Deep Learning can enable visual identification of objects at accuracy levels similar to those of a human being. We started developing GAIN in 2016, and a dedicated team was set up for this purpose in 2018. TOMRA provides us with a lot of support, and the sector is growing rapidly – with the aim of further expanding the range of applications.

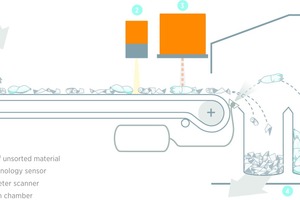

recovery: How does the GAIN module work in the sorting process?

Dr. Daniel Bender: The AUTOSORT system analyses the plastics in the NIR (near-infrared) range and separates PE plastics from the remaining materials correspondingly. The PE cartridges are not diverted out, since they consist, superficially, of material detected as „good“. Now another sensor-based system – GAIN – is implemented, with a camera which, like humans, processes information from the visible spectrum of light. This is, in hardware terms, a relatively simple system – it‘s the software that makes the difference. At the end, the undesirable materials identified both by the AUTOSORT and by the GAIN module are blown out by arrays of air jets.

recovery: Will there possibly be even more application for GAIN in the future?

Dr. Daniel Bender: Yes, there will be further applications. The rule of thumb for use with cameras is that all objects that a human being can distinguish in the camera image can also be sorted by sensor-based sorting with a Deep Learning System. However, the effort of learning GAIN is quite high, i.e. for single applications Deep Learning methods are not yet suitable in their current form.

recovery: How complex is it to install this new module?

Philipp Knopp: GAIN can be very easily retrofitted

to AUTOSORT machines in one working day. In the development we paid special attention to the fact that GAIN is a modular, flexible system.

recovery: Does the user need any special knowledge?

Philipp Knopp: No, the user does not have to program himself. When he buys our solution, he expects our technology to solve his problem and help him to operate his plant in a more favorable way.

recovery: After-sales service will certainly not be unimportant, with such high-tech machines …

Philipp Knopp: Since TOMRA develops the used technologies in-house and also manufactures the machines within the company, we can react quickly and systematically to customer enquiries.

recovery: How do you perceive future development in the field of Deep Learning?

Philipp Knopp: We see huge potential in Deep Learning. Finding new technologies for advancing the recycling industry is indeed our field of expertise. From packaging, via film sorting, wood, minerals – every technology has its limits, but the Deep Learning method has the potential to expand these applications to permit much more accurate sorting.

recovery: Many thanks to you for this highly interesting talk!