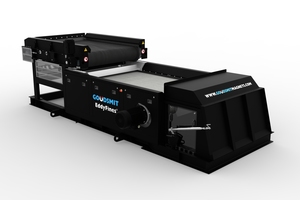

Goudsmit Magnetics: special edition Eddy-Current Separator

How it works

A head roller magnetic separator is a conveyor belt system with integrated magnetic head pulley, the magnetic strength of which can be chosen to match the application. A spreading module or a series of wide belts or sieves produces a wide spread on the belt of the eddy current separator, better distributing the capacity and layer thickness. The belt speed is adjustable, which allows the magnetism to be calibrated to the ballistic effect of the specific product and is therefore an additional adjustment parameter. The magnetic conveyor captures iron particles or iron-containing slags as small as 0.1 mm and releases them on the underside, where a funnel collects and/or carries them away. This can also be done with a separation partition. The remaining (practically non-magnetic) fraction continues on its way to the eddy current separator, which handles the separation of fine NF metals (>0.5 mm), such as aluminium, copper, silver and gold. The head roller magnetic separator is available in various strengths, such as 1800, 3000, 6000 and 9000 gauss, to match the application. The 1800 and 3000 gauss models are used for processing incinerator slags. The stronger, 6000 and 9000 gauss versions are used for other fractions, such as WEEE and ASR.

Hall B6, Stand 316