Heavy-duty wheel loader use in the waste management industry

Westsächsische Entsorgungs- und Verwertungsgesellschaft mbH (WEV) operates two waste disposal facilities in the south of Leipzig: the Cröbern central landfill (ZDC) and the Cröbern mechanical-biological waste facility (MBA). The site chosen in 1992 is located on a dump landscape left behind by lignite mining and is far away from the nearest residential development.

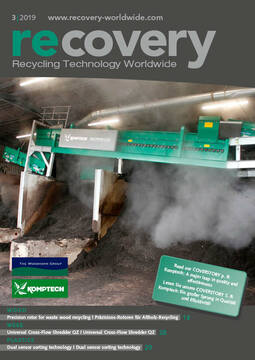

The MBWT currently has five HYUNDAI wheel loaders, four handling excavators and a rent converter as large-scale equipment. At the heart of the fleet are the four Hyundai 770-9A and HL970 wheel loaders.

Their task is to transfer and load the material in the preparation process. The household waste is pre-shredded and sieved in a sieve drum to < 80 mm, after which it remains in the intensive rotting chamber for five weeks (44 tunnels with a capacity of 220 t each). During the rotting process, the waste is moved twice – for cleaning work, a Hyundai Skidsteer loader with sweeper and completely lockable cabin and seca protective ventilation system is used. The post-rotting is fed by the wheel loaders – a windrow turner moves the piled up material regularly.

The Hyundai wheel loaders – all supplied by Tecklenborg Baumaschinen, headquartered in Leisnig near Leipzig, Germany – are powerful and fast and take care of feeding the post-rotting material and loading it. Like all machines at WEV, the wheel loaders are equipped with Seca protective ventilation systems for filtering and conditioning the cabin air.

The machines can operate up to 2000 h/a. The HL970 wheel loaders are equipped with 4.5 m³ high-tipping buckets so that they can also load high-sided trucks and containers.

„Two-shift operation on five days a week demands a lot from the wheel loaders (all equipped with rock tyres),“ explains logistics division manager Marco Berger. The wheel loaders are purchased and serviced by Tecklenborg. Decisive for the South Korean products is the very good and fast service of the dealer Tecklenborg, the competent advice and the resulting very high availability. „In plant operation“, explains Berger, „nothing is given to the machines. Heavy loads, high temperatures, dust accumulation and continuous operation are the order of the day. Reversible fans are absolutely essential – standard equipment at Hyundai“.

In addition to the rock tyres and the protective ventilation system, the numerous optional extras include central lubrication and the weighing device that Hyundai uses as standard – although it is not calibrated, it is sufficiently accurate to protect the trucks from overloading. Tecklenborg also took care of the STVZO approval requested by the customer for the wheel loaders.

Features of the Hyundai HL Wheel Loader Series

The new wheel loader series consists of eight wheel loaders with operating weights from 13 100 to 31 000 kg and for bucket volumes from 2.6 to 5.6 m3.

In addition to reduced fuel consumption, the new HL series offers numerous other environmentally friendly attributes. An automatic engine cut-off keeps fuel consumption and emissions under control. The operating mode and the time the engine runs „empty“ can be set by the driver according to the working conditions, which in turn increases efficiency.

The standard five-speed transmission with lock-up clutch further reduces fuel consumption. An ECO display enables economical operation by frequently checking the machine status. The ECO display changes colour with engine torque and fuel efficiency. In addition, fuel consumption values such as average consumption and total consumption are monitored and displayed on the monitor.

The standard ECO accelerator pedal distinguishes between economical operation and power operation - fuel consumption is significantly lower in economy mode. A „speed limit“ can be set between 20 and 40 km/h for HL Series drivers.

ICCO (Intelligent Clutch Cut-Off)

In H mode, the ICCO intelligent clutch separation function reduces power dissipation at the torque converter. The lower heat generated by ICCO benefits fuel efficiency overall. The hydraulic limited slip differential increases productivity and saves fuel by preventing tyre slip.

New cab with more comfort

Quiet, safe and comfortable, plus 10 % larger - the new ROPS/FOPS cab with fully adjustable seat offers the driver an ergonomic and extremely pleasant workplace. It is highly soundproofed and uses state-of-the-art sound reduction techniques to ensure maximum peace of mind when working in noisy environments such as gravel pits or waste dumps. The new air conditioning system maximises heating and cooling performance through optimised airflow in the cab. The electro-hydraulic joystick allows easy guidance of attachments for productivity and fatigue-free operation.