Huge mountains of old photovoltaic modules

Photovoltaics are already making a major contribution to energy production and this will continue to grow, because solar energy is considered a sustainable alternative to oil and gas. However, the photovoltaic modules also bring some environmental problems. The processing of the contained silicon costs a lot of energy, thin-film modules emit nitrogen fluoride during production, which is harmful to the climate, recycling has not yet really been ramped up and the efficiency of the solar modules has room for improvement.

Photovoltaic systems use the photoelectric effect to convert light into electrical energy. A special feature is the silicon in the solar cell. This metal has the special property of being charged by the electromagnetic radiation of sunlight. The charge is bundled by a layer system and converted into usable electricity.The recycling industry is becoming more and more dynamic in the area of used photovoltaic (PV) modules – huge quantities of used PV modules are expected. The report of the International Energy Agency (IEA) from 2022 shows that up to 80 million t of old PV modules are expected worldwide. For Germany it is forecasted that 400 000 t – 1 000 000 t in 2030 and 4.3 million t by 2050. Most old PV modules are expected in the following countries: 1. China, 2. USA, 3. Japan, 4. India, 5. Germany. The research company Rystad Energy estimates 27 million tons of old PV modules worldwide from 2040 onwards.

Recycling of PV modules

Disused PV modules usually have a lifespan of around twenty to thirty years. However, solar systems are also being phased out due to reduced performance, weather damage and product guarantees.

Citizens have the option of handing in old PV modules to the recycling center free of charge. The PV module manufacturers are legally obliged to take back PV modules free of charge and to transfer them to the material cycle. Many manufacturers have been using the industry-wide PV recycling system „PV Cycle“ since 2010. Other take-back providers include PVEX and Take-e-way. The materials glass and aluminum are mainly recycled here. The recycling of metals from solar cells is not yet implemented.

In Germany, a recycling rate of 80 % must be achieved when recycling PV systems, which is determined by the WEEE directive of the EU. In practice, however, it has been shown that up to 95 % of the materials are often recycled.

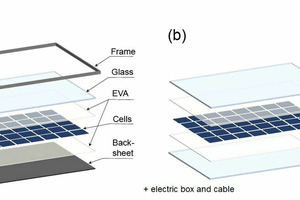

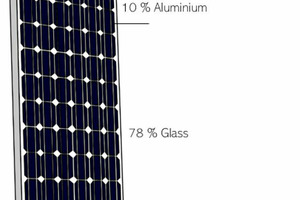

Both mono- and polycrystalline PV modules can be easily recycled: They consist mainly of glass, aluminum and plastics (Fig. 1)). Up to 95 % of the PV module is made from it (Fig. 2). The remaining 5 % are metals like silicon, silver, copper, tin and lead. Only the aluminum, glass and copper are currently recycled, but not the solar cell with the valuable metals. Since the production of metals, especially silicon, produces high CO2 emissions, the focus should also be on the recovery of these materials.The difficult thing about PV module recycling is breaking up the firmly bonded module components and recovering the materials they contain in high purity. Since the WEEE recycling quotas are easy to meet with the separation of the aluminum frame, cable and glass. There are no incentives to invest in other recycling technologies. Adjustments to the recycling requirements are expected, such as quotas per ingredient should apply. Therefore, the metals silver and silicon would also have to be recycled.

Silicon recycling

One of the most important and valuable components is the semiconductor material silicon. The Fraunhofer CSP has developed a recycling process with which the silicon can be recovered on an industrial scale.

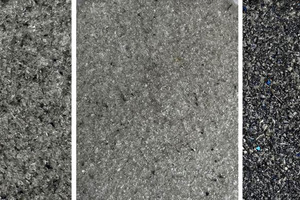

After separating the aluminum frame (Fig. 3), the junction box and the glass plates, the solar modules are shredded. The material fraction in the size range 0.1 – 1 mm is electrostatically separated in the hamos KWS (Fig. 4) into clean metals and glass (Fig. 5).

The metal fraction contains silicon, silver, copper, tin and lead. In the next step, wet-chemical etching is used to remove backside contacts, silver contacts, anti-reflective layers and emitters. It is then possible to convert the silicon into standard processes.

Furthermore, an additional material flow in the size range 1 – 4 mm is screened. This consists of busbars containing silver – so-called busbars – which can also be separated from the glass in the hamos KWS electrostatic separator (Fig. 6). The recovered glass is mainly used to make cellular glass (foam glass). Processes for better glass separation are currently being tested.

hamos GmbH is in the process of testing a recycling process in which the time-consuming dismantling of the aluminium frame and the connection box is no longer necessary.

In this recycling process, the feed line (copper cable) is cut off and then the complete PV module is shredded. At the end of the process, different, clean glass and metal fractions are obtained. The advantage of this recycling process is that high throughputs can be achieved.

Due to the large number of old PV modules expected, the hamos recycling process could be used to recover the metals from old modules on an industrial scale. The special feature of the recycling concept is the purity of the recyclates.

Increasing the efficiency of solar modules

The production of photovoltaic systems consumes a lot of energy, large areas are necessary and the efficiency of the solar modules has room for improvement.

Most module manufacturers now use monocrystalline solar cells almost exclusively. They have an efficiency of up to 25 %. If a large area is available for the photovoltaic system, polycrystalline modules are sometimes also used, which achieve the same performance with a larger number of cheaper modules. Monocrystalline cells can be distinguished from polycrystalline cells by their color. These are black, polycrystalline solar cells have a bluish color.

With a photovoltaic module with an average efficiency of up to 25 %, the largest part of the light spectrum of around 75 % is not used. In the near future, other technologies could eliminate these problems.

Solar cells made from ferroelectric materials

The “perowskit” cells are made of ferroelectric materials and have an efficiency of ~29 %. The special feature here is that the perowskit cells are applied to a conductive substrate by spraying or brushing. Practical concepts could come onto the market in a few years.

Multiple cells

There are already solar cells with an efficiency of ~48 %, these multiple cells consist of different semiconductor layers. Each semiconductor layer uses different light spectra. These multiple cells are not yet marketed.

Solar film made from organic waste

AuREUS solar film can work 20 – 50 % longer than ordinary panels and is light and flexible. Here, solar cells are made from harvest waste, the fluorescent particles. The fluorescent particles are encased in a layer of resin and then generate electricity through the sun‘s rays - even when it‘s cloudy.

Solar flowers

A solar system from Smartflower can generate up to ~6000 kWh annually. A shadow-free area of ~27 m2 is required. The solar system looks like a sunflower and can turn and tilt its „solar leaves“ to the sun so that the rays are always at the optimal angle and can be recorded. If a storm comes up, the facility closes automatically.

Solar paint

Researchers are working on a paint that can be applied to a wall and is intended to generate electricity. Electricity can be generated by small titanium dioxide particles in paint coated with cadmium dioxide or cadmium selenide and applied to a conductive film. Another institute is also researching a paint that removes moisture from the air and can split water molecules. What remains is an energy carrier: oxygen and hydrogen.

Solar window

The company ubiquitous energy offers windows that can generate electricity. These windowsuse transparent solar cells and use only ultraviolet light to generate electricity. This current is then carried by salt molecules to solar strips at the edge of the window. The efficiency is ~ 10%.

There is further research in South Korea. Experiments are being made there to punch tiny holes in the silicon cells. The holes are arranged in such a way that an optical illusion is created. In addition, the perforated silicon cells let the light through without any discoloration. The efficiency is ~12 percent.

We can be curious to what extent the efficiency of the solar modules will increase and what the appropriate recycling concept could look like.

In order to strengthen the recycling and reuse of PV modules, the German Environmental Aid DUH, together with partners from the solar and waste disposal industry, published a white paper with potential for improvement in 2021. The White Paper makes the following demands:

Module design adjustment for better separation of materials

No lead components

Limits on silicon and silver usage

Strengthen reuse and recycling

Ensuring reusability through expert transport

Expansion of collection and disposal structures

Among other things, it is made clear that recyclers need an incentive, for example through recycling specifications per recyclable material and a plannable and secure material flow, in order to invest in new and high-quality recycling technologies and thereby achieve resonable revenues for the recycled materials.

Author: Selinda Sliz, Head of Marketing, hamos GmbH