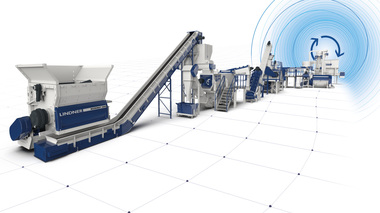

Improvement of output quality in film washing systems

The latest in a series of developments for PE film recycling from Lindner Washtech is the Film Examiner. It is placed directly in front of the extrusion phase as a final process to improve the product quality. The device reliably separates small hard contamination particles which are extremely difficult to remove using traditional methods within the washing line due to their specific density and size. These include in particular rigid plastic particles of PP or HDPE, and in addition light aluminium particles and small wood flakes.

The Film Examiner is mounted directly in the air stream after the thermal drying process, utilizing the different flow characteristics between small contamination and the light film flakes in order to achieve reliable separation. The air flow is adjustable by means of sliding gates in order to optimise the separation process. The contamination separated simply falls into the collection bin which can be easily monitored and emptied.

Georg Krenn, technical manager of Lindner Washtech: „Improving output quality is our customer’s focus today. The Film Examiner without doubt provides a compact and inexpensive solution to further improve product quality and reduce operational costs supporting our customer key goals. Retrofitting of existing plants with the Film Examiner is fast, easy and highly cost-effective.”