Innovation in separation – Solutions for separating and sorting

Protecting the environment, conserving resources, recycling valuable materials - combining ecological awareness and economic interests is a core issue of the present. The engineering company TRENNSO-TECHNIK® from Weissenhorn, Bavaria recognized this more than 30 years ago. With their pioneering solutions for separating and sorting a wide variety of materials, they are among the market leaders in their segment.

This applies in particular to the three core competence fields of recycling, bulk solids and foodstuffs. Worldwide, they build plants individually adapted to the needs of their customers. These can consist of individual machines as well as modules, which impress with their innovative technology and the resulting outstanding sorting quality. Another quality feature is the robust construction of the components, which guarantee many years of safe operation for the customer.

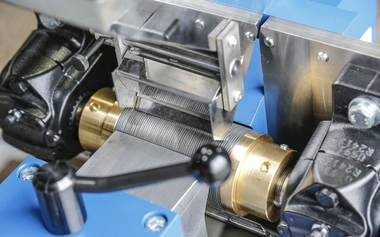

The TRENNSO-TECHNIK® machine portfolio includes screening machines, separating tables and air classifiers. The corresponding conveying and dosing technology such as elevators, screw conveyors and rotary valves complement the technology of the proven dry separation process. The highly productive plant technology is worldwide successfully in use. The models in the diverse product portfolio can include all complementary systems in addition to the core components. These include crushing and grinding technology, magnetic and eddy current separation as well as inductive and sensor-protected sorting technologies.

Hall B6, Stand 534