Innovative cleaning ship frees the sea from plastic waste

Shimmering turquoise water, white sandy beaches and swaying palm trees:

the Indonesian islands are among the dream destinations of many holidaymakers, destinations such as Bali entice with picturesque beach settings and unique nature. But many small islands off the Indonesian coast are far from pristine postcard idylls. Where once shells and coral remains washed up, today – unlike in the 1970s – a flood of plastic waste is piling up.

The environmental organisation The SeaCleaners is working to rid the world‘s oceans of plastic – with a sailing, almost emission-free recycling factory.

Although the G-7 announced more money for ocean protection on this year‘s World Ocean Day, an estimated 10 million t of plastic waste still end up in the oceans every year (Source: Plastics Statistics). If the current trend continues, the amount of plastic waste polluting the oceans will increase to around 29 million t/a by 2040. This corresponds to 50 kg for every metre of coastline in the world. Plastic pollution is therefore one of the six biggest environmental disasters according to the UN. About 1.5 million animals already die every year from plastic pollution, 14 000 species are affected. Around 90 % of seabirds and 30 % of fish ingest plastic during their life cycle – and so it ends up back in human stomachs.

Intensive research and development for a future-oriented drive system

The SeaCleaners is the name of a marine conservation organisation that wants to use a new, technical approach to ensure that the litter from the oceans is skimmed off – without placing an additional burden on the environment. The vision: a ship that frees the oceans from plastic waste and produces no new emissions in the process. The name: Manta – derived from the giant manta rays that glide silently through the oceans.

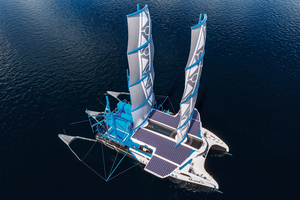

The idea was born many years ago and since its foundation in 2016, The SeaCleaners have been turning it into reality piece by piece with the help of donors, sponsors and an international team. 58 engineers, technicians and researchers, 5 research labs, 17 partners and contractors worked on the detailed design and on-board technologies of the Manta from 2018. After three years and 45 000 hours of intensive research and development, the concept for the 56.5 m long, 26 m wide and 1600 t vessel was ready – a gigantic catamaran whose technology uses marine waste that can no longer be recycled for its own propulsion, fishes it out of the sea, sorts it and recycles it via waste-to-energy plant. A model that could become a role model for future generations of ships – a ship that cleans the oceans without further polluting the environment itself.

For the engineers, the propulsion concept in particular represented a special challenge within the ambitious project. The double-hulled catamaran gets its propulsion from a sophisticated interplay of different renewable energy sources. These include around 450 m² of solar panels on deck, two wind turbines and hydro generators as well as two large main sails that automatically turn into the wind. The overall system is supported by a specially developed hybrid engine that drives two propellers on the high seas. A special waste-to-energy plant additionally feeds the system.

The sails are the Manta‘s main propulsion system and help minimise the catamaran‘s energy consumption, CO2 emissions and operating costs. The Manta can operate at least three quarters of the time without the use of fossil fuels, making it the first working vessel with such a high degree of energy autonomy. In compliance with international regulations to ensure crew safety, the Manta is now only equipped with two emergency diesel engines to ensure manoeuvring in situations dangerous for the crew and returning to port at low speed.

Collecting the floating waste

The Manta, with its alternative energy sources, moves at an average power of 6 knots and top speed of 12 knots and has an interaction radius of 3500 nautical miles (6500 km). Once the vessel arrives at its destination, the speed is reduced to 2 to 3 knots.

By extending the nets located at the stern, the width of the manta ray is almost doubled to 46 m in the area of operation. In doing so, the ship reaches a collection depth of one metre. This allows floating waste to be collected in the nets. Surface cleaning makes it possible to combine two requirements: On the one hand, the floating objects on the surface have not yet fragmented and decomposed into microplastics. On the other hand, it is mainly single-use plastics that float on the sea surface and have a low recyclability but a very long degradation time.

In addition to trawl nets, which may only be used in areas where trawling is also permitted, so-called collection mats are used as a supplement. This system is mounted between the hulls of the catamaran and transports the plastic parts permanently on deck. This means that a large part of the plastic can be recovered directly. However, if there are parts that are too bulky or heavy for the nets and mats, the crew of the Manta can still use two deck-mounted cranes.

Once retrieved from the sea, the plastic parts are transported via conveyor belts to sorting. A distinction is made between three types of waste: plastic that can no longer be recycled but can still be used for energy, materials that can be recycled (such as metals) and residual waste that can no longer be used. The latter is kept in various interim storage facilities until the next stop at a port, where it is professionally recycled or disposed of. To work as efficiently and flexibly as possible, the Manta is equipped with two auxiliary boats. These are the specially developed types Mobula 8 and Mobula 10 – smaller collection boats with a length of just over 9 m and a collection capacity of 8 m³. The main areas of application are estuaries and mangrove areas, which the Manta cannot enter itself due to its size. In combination, Manta and Mobula can thus create a daily collection capacity of up to 72 t of waste.

Per year, the main vessel alone can collect up to 10 000 t of waste from the sea from a size of 10 mm and up to a collection depth of one metre below the water surface. Thanks to its high energy autonomy, the Manta can operate 300 days a year at sea – which also puts it far ahead of other cleaning vessels.

Waste-to-Energy Unit recycles marine litter that can no longer be recycled

Just as giant manta rays swim with their mouths open, filtering the water to swallow plankton, jellyfish and other crustaceans, the catamaran Manta swallows plastic waste floating at sea to power its propulsion equipment and carry out its cleaning missions.

Between the hulls, under the ship‘s platform, are slanted collection belts that carry the marine debris into the hull of the ship to the sorting facility. There it is manually separated into the fractions metal/glass (still recyclable), plastics (generally no longer recyclable due to the salt water) and residual waste (must be disposed of). Organic materials, such as wood and algae, are returned to the water.

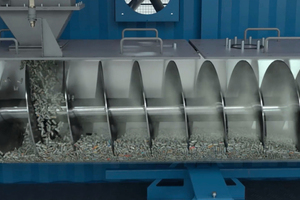

After sorting, the collected recyclable plastic parts are prepared for the subsequent work steps. The plastic waste is shredded and compacted to increase its energy efficiency. In this pelletising process, the material is shredded to increase its energy efficiency in the further process. The plastic pellets are then directly energetically utilised in the waste-to-energy unit on board. The aim is to generate as much energy as possible to propel the ship from the plastic marine debris that can no longer be recycled. The size of the individual components is determined so that the space in the hull of the ship is optimally utilised.

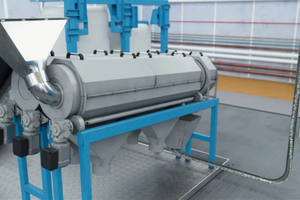

The SeaCleaners‘ waste-to-energy unit relies on chemically and thermally splitting the supplied plastic into three different components. The main product is a synthesis gas, 90 % of which is produced. This gas can generate electricity by means of an incinerator and a turbine. This produces significantly fewer emissions than the use of marine diesel. In addition, the resulting solid residues, which make up 5 – 10 % of the processed plastic, are stored and further processed on land, for example in bitumen for road construction. Residual emissions are filtered and processed according to strict EU regulations. The third product is heat emissions, which are used, for example, for heating requirements on board.

Everything that cannot be processed immediately in the pyrolysis is stored on board. In total, the Manta has 206 m³ of storage space below deck and in the big bags. Converted, the storage volume is about 50 t. In addition, there are two collection containers, each with a size of 33 m³. These are intended for fishing nets and for hazardous waste that cannot be recycled. During a mission lasting 3 weeks, about 1260 t of plastic waste are to be recycled.

The maximum mission duration of the Manta is 20 h/d. In order to be able to use this as effectively as possible, the most modern technical solutions from partners will also be used. For this purpose, satellite-based waste detection was further developed together with CLS (Collecte Localisation Satellites). Satellite orbits laid out in the area of operation can thus be used to determine exactly how an accumulation of rubbish is moving in the sea and how the manta ray can most effectively advance into these areas.

Floating research laboratory

Research and further development are an important part of the concept. In addition to the aspect of cleaning the sea, the ship will house its own research station. The Manta can accommodate a crew of up to 34 people. 22 of them are necessary for the operation and maintenance of the facilities, 12 further places can be occupied by guests as well as international teams of researchers and scientists. These can work in a fully equipped laboratory and gather further insights into the effects of marine pollution on humans – or deepen their observations on the flow behaviour of plastic objects at sea. The SeaCleaners follow an „open data“ approach.

It is important to the marine conservation organisation that the Manta is also a kind of training ship and serves as a role model. There is a specially designed educational module for this purpose. This is open to the public during port calls and, with the help of information material, aims to sensitise people to a more sustainable approach to the sea and to educate them about the consequences of littering the oceans. Various possibilities to do something against plastic waste oneself through projects are also to be presented and promoted here. „The oceans are a vital source of oxygen, a climate regulator, a nutritious ‚sea‘, a guarantor of our health, a playground and an inexhaustible source of inspiration,“ says Valérie Amant, Spokesperson for The Seacleaners. „But today they are in grave danger. Millions of tonnes of plastic are dumped into the oceans every year. Our goal is to collect the waste at sea and help raise awareness in developing countries that the oceans are one of our most important sources of life.“

Of course, the team of The SeaCleaners knows that the problem of marine pollution cannot be solved with a boat, but the prototype of this new type of cleaning vessel is intended to be a start and find imitators. The dinghy of the Manta will set sail this year, and the Manta itself will be launched in 2025. And the first location has already been determined: the waters around the Indonesian islands.