Innovative technologies for sorting PET, HDEP and PP packaging by color

Demands for a functioning circular economy are growing louder. From society to business to politics, there has never been greater awareness or consensus about the urgent need to recycle raw materials. As far as plastics are concerned, growth within the recycling industry is influenced by legal requirements, regional recycling targets, and increasing demand for recyclate made from PET, as well as HDPE and PP.

The reuse of plastics, in particular, has enormous potential. The VDMA Waste and Recycling Technology Association reports that state-of-the-art recycling technology is already equipped to recycle a large proportion of the 14.4 million tons of plastic processed in Germany every year. These capabilities are essential for climate protection, as a single ton of recycled plastic can save between 1.45 and 3.2 tons of CO2 equivalent.

Between its action plan for establishing a circular economy and the new plastic tax which took effect in January 2021, the EU Commission has taken a number of important first steps to close the loop and reduce plastic-related greenhouse gas emissions. All stakeholders along the supply chain can expect both new opportunities and new challenges.

From waste collection ...

As the first step in any waste management system, waste collection has a decisive impact on the system’s overall performance. There are a number systems in use in Europe today for collecting household waste. The explicit separate collection of packaging and other household goods (consisting largely of plastic, aluminum, paper, and glass) is one compelling solution for increasing the amount of waste diverted to recycling plants.

... to recycling

Manufacturers and consumers alike have a role to play in ensuring that waste from plastic packaging can be successfully recycled. A basic prerequisite of efficient waste processing is the sorting of waste by type. Packaging waste can only be recycled if it is disposed of properly.

The effort involved in recycling a piece of packaging is much higher if the item consists of several layers of material or a combination of materials that cannot be separated after use. In some cases, packaging consists of several types of plastic bonded into a compound. Compounds are usually sorted into a single material fraction, thereby reducing the fraction’s overall purity.

Politicians are responding to the challenges faced by the recycling industry by passing ambitious legislation, such as Germany’s Packaging Act. Manufacturers can anticipate new challenges in designing and developing products in a sustainable manner. In accordance with legislation from the EU Commission, it will soon be required that all packaging made from non-renewable materials is designed and manufactured in such a way that it can be reused and recycled.

Securing the market availability of recyclate could help reduce reliance on primary raw materials going forward. Achieving this will require effort from recyclers, manufacturers, and consumers alike.

... to sorting

More than any other factor, material sorting has the largest impact on the quality of secondary raw materials. Plastics to be recycled often contain impurities stemming from a variety of sources. For example, if materials are not correctly separated and sorted during the recycling process, contaminates and incorrect materials will be shredded and mixed into the recyclate. When the contaminated recyclate is processed further, the end-product may display quality issues. This can lead to complaints.

Next to color errors and the wrong types of plastic, metal particles may also be cause for complaint when present in recyclate. If metals go undetected, they may damage processing machinery and lead to losses in production efficiency.

Achieve the highest purity

with sensor-based sorting systems

When it comes to containers such as bottles, there is tremendous variety in packaging design. As such, recycling these containers requires sorting them by material type, plastic type, and color. Coloring differs tremendously, from transparent, to partially transparent, to opaque, and combining materials indiscriminately can cause recyclate to have an unattractive color. In order to produce high-quality packaging from recycled materials, recyclate must exhibit high degrees of material and color purity.

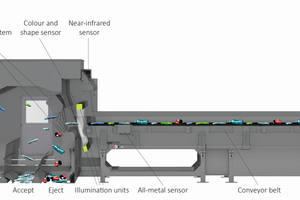

Sensor-based material analysis systems and sorting equipment provide a solution to this challenge. They precisely sort plastic waste by color and material type, while metal separators reliably detect and remove even the tiniest metal particles from the recyclate. These technologies make it possible to achieve premium quality recyclate even with low-grade starting materials.

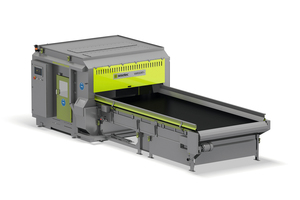

Sesotec VARISORT+ FLASH:

the sorting system with an eye for color

Sesotec has been developing solutions for sorting plastics by color for over 20 years. Through extensive experience with sorting equipment for plastic flakes as well as equipment that can separate transparent and opaque glass, Sesotec now offers technologies capable of sorting plastics by color at the container, flake, and regrind level. Special attention was paid here to developing sensors that can detect colors in different presentations.

By gathering both transmitted and reflected signals, sensors can glean additional information with which to more accurately sort different objects and materials. This can lead to significant performance advantages in the sortation of transparent and semi-transparent colors.

In addition, it is also possible to detect even the finest differences in contrast, such as in transparent containers ranging from clear, to light blue, to yellowish. This makes it possible to further improve the color purity of material fractions as necessary. An added benefit of this technology is that detection takes place as the materials are projected into the air, thereby eliminating environmental influences, such as interference caused by the conveyor belt.

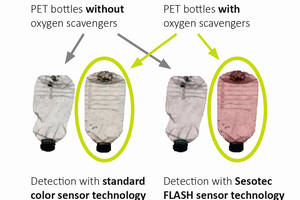

VARISORT+ FLASH technology offers the advantages of two systems in one; it detects color by measuring both transmitted and reflected light. An additional lighting and camera device is installed, enabling the system to recognize even the most challenging materials, such as difficult-to-distinguish colors (e.g. opaque, opaque white, silver, and light gold) and functional materials containing additives that prevent exposure to light and oxygen.