Kuljetusrinki transforms waste handling with Heavy Picker Robots

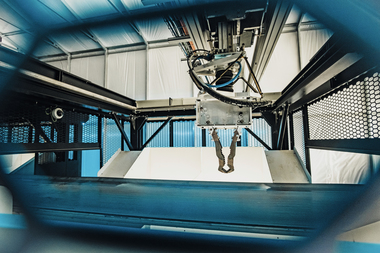

Kuljetusrinki, a waste management and environmental services company based in Helsinki/Finland, has introduced a ZenRobotics® fully automated and independent waste sorting station into its new waste management facility, focusing on the final sorting phase of the process. The station includes three ZenRobotics Heavy Picker robots, which have brought speed, precision, and the ability to work around the clock, 24/7, at the company’s waste handling facility.

Founded in 1989, Kuljetusrinki specialises in low emission transportation services for waste materials, collecting from various sectors, including construction sites, retail stores, and manufacturing industries. Their waste management site in Tattarisuo/Helsinki, plays a pivotal role in sorting and handling these materials efficiently.

“Before embracing ZenRobotics Heavy Picker robots, our waste handling processes relied heavily on manual labour alongside appropriate machinery,” said Markus Närhi, CEO at Kuljetusrinki Oy. “However, this approach had limitations – it was slower, less precise, and resulted in suboptimal sorting outcomes. We turned to ZenRobotics for a technological upgrade to enhance our operations.”

The solution was a ZenRobotics Standalone Solution, a turnkey solution that incorporates the benefits of AI-powered sorting at a low operation cost. The fully automated sorting station, powered by three ZenRobotics Heavy Pickers, works faster and more accurately compared to manual sorting, boosting productivity at the site. Additionally, it is totally independent from other operations – meaning it can run unmanned 24/7, further increasing throughput.

Kuljetusrinki worked closely with ZenRobotics throughout the implementation process to ensure a seamless integration of the technology into their waste handling operations. The standalone solution is flexible and easy to operate and was quickly ready for use. The robots employ high IQ AI powered recognition systems that outperform human capabilities at the site. Their speed and ability to handle objects of varying sizes, weighing up to 40 kg, improve accuracy and cost-effectiveness, with the three Heavy Pickers achieving up to 6900 picks per hour.

Improved sorting outcomes and value creation

The Heavy Picker robots at Kuljetusrinki excel in picking a wide range of materials, including wood (A/B/Painted), inert, rigid plastics, ferrous and non-ferrous scrap metals with a precision that has significantly improved the quality of the sorted materials. The investment in Heavy Picker robots has already shown promising results, with Kuljetusrinki creating value both financially and from a sustainability perspective by diverting different materials from incineration to recycling and reuse. Notably, safety procedures have been elevated with the introduction of safety cages around the robots to ensure a secure working environment for human operators.

Speaking on the investment of ZenRobotics Heavy Picker robots at their site, Markus Närhi continued: “Our vision is to be an enabler, providing the manufacturing industry in Finland with the raw materials they need in a sustainable way. We are excited about how ZenRobotics robots can identify the different materials, compared to the human eye – this a significant step up for us. This accuracy, along with the speed at which it can sort out the most valuable materials are all benefits we are seeing from the implementation of this technology at our site. The entire process of building a waste material recovery facility with ZenRobotics has been inspiring, and we look forward to continued collaboration together as this technology evolves.”

Juha Mieskonen, Sales Director, ZenRobotics said: “The integration of Heavy Picker Robots at Kuljetusrinki exemplifies how cutting-edge technology can transform waste handling. The Heavy Picker robots have elevated sorting outcomes, efficiency, and safety, while also contributing to environmental sustainability.”