Lindner-Recyclingtech GmbH

At IFAT 2024 Lindner will be showcasing product innovations in shredding as well as efficient system solutions. The focus will be on classic input materials such as commercial, industrial and municipal solid waste, waste wood and scrap, and the mechanical and chemical recovery of plastics. At an expert talk on the Orange Stage, Lindner will also present innovative approaches to successfully address chemical recycling demands.

‘Be A Waste Transformer’ – with this guiding principle in mind, Lindner focuses on the client, their individual needs and the implementation of all-in-one solutions. As a recycling pioneer and manufacturer with decades of experience in waste management and plastics recycling, Lindner draws on extensive expertise.

Be A Waste Transformer – keeping this principle in mind, Lindner focuses on the client, their individual needs and the implementation of comprehensive concepts

Be A Waste Transformer – keeping this principle in mind, Lindner focuses on the client, their individual needs and the implementation of comprehensive concepts

© Lindner

Innovating the recycling process

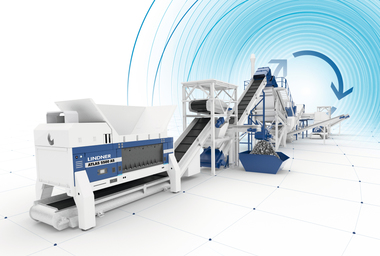

Lindner will be presenting two new products at IFAT 2024. The new stationary universal shredder with twin-shaft technology is primarily geared towards waste wood, industrial and commercial waste and scrap. The second product innovation, an electrically powered semi-mobile single-shaft shredder with an independent track drive, covers an even wider range of input materials thanks to its modular cutting system. “We are looking forward to showcasing our semi-mobile single-shaft shredder. The modular cutting system means it offers maximum flexibility. Depending on the material stream and the output material requirements, you can choose between a blade or pointed knife system. We will also be exhibiting these two rotor variants at IFAT 2024,“ says Gerd Tischner, Sales Manager at Lindner.

Cutting system innovations

The Komet series, the benchmark in secondary shredding, offers improved ease of maintenance thanks to screwable knife holders. In addition, a new Urraco shaft pair will be showcased, which has been specifically developed for scrap recycling and significantly increases efficiency. If used as a coarse primary shredder upstream of a hammer mill or a cross flow shredder, it considerably maximises the hammer mill’s output and reduces the need for maintenance.

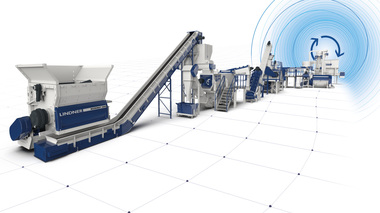

System solutions for mechanical and chemical recycling

As a manufacturer of shredding solutions, Lindner has had an in-house engineering department for decades that offers all-in-one mechanical and chemical recycling solutions. The portfolio ranges from commercial and industrial waste to a wide variety of plastics, dry and wet applications, and chemical recycling. “Since 2003, we have been implementing all-in-one solutions for standard applications such as commercial and industrial waste, bulky waste etc. We supply both individual shredders and comprehensive plant designs. Our expertise means that we also cover a wide range of wet and dry mechanical applications in plastics recovery – providing solutions from shredding, sorting and washing to granulating. Whether films, rigid plastics, big bags – in-house or post-consumer recycling – we are one of the big market players in this segment. We are also pleased that our solutions are already being used successfully in chemical recycling and we will be speaking about this topic on the Orange Stage this year,“ says Michael Lackner, Managing Director at Lindner.

Booth B6, 251/350