Material stock always available with 3D LiDAR

Optimizing recycling plants through collecting and processing status and process data is a vital factor in achieving a comprehensive circular economy. However, one question that has yet to be answered is how much waste material is kept in these plants. A specialized 3D LiDAR sensor solution is now available, which provides up-to-date inventory information at any time and automatically feeds it into the material flow management software.

The waste and recycling industry faces the significant challenge of transitioning towards a more comprehensive circular economy, as outlined in a position paper published by the German Federal Environment Agency in November 2022. This involves achieving resource cycles that are as closed as possible. The Environment Agency recommends numerous measures for this transformation, including „expanding the information base and monitoring of the circular economy“ [1].

Collecting and processing a large amount of data is essential to achieve this goal. Digital solutions are vital for gathering and utilizing information about the entire value-creation process. However, some data is not easily accessible, such as real-time recording of waste volumes in recycling plants, for which there has been no practical solution until now. With 3D LiDAR technology, recycling plant operators now have a digital technology that provides accurate waste inventory data at any time, helping them improve recycling processes significantly.

1 Digital mapping of waste streams

The importance of digitalization has led to the realization that data is the most valuable tool for the efficient and effective recycling of raw materials. In the case of waste management in the recycling industry, data is particularly essential in creating transparency about waste streams. This transparency is the basis for maximizing the recycling rate and operating the recycling plants in an economically profitable manner.

2 The situation today: Inadequate data

on waste inventory

Currently, recycling plant operators have insufficient and imprecise data regarding the amount of waste being stored. This issue is mainly caused by missing technologies, large volume fluctuations, and a lack of proper documentation:

Technological shortcomings

Thus far, waste management and recycling companies have mainly relied on truck weight data during the delivery and pickup of materials, along with employee estimates, to determine their material inventory. However, the weight data recorded during deliveries provides no insight into the quantities of material stored in various locations within the facility at any given time. Even experienced employees are unable to estimate the volume of large piles of material accurately, resulting in significant discrepancies from actual quantities. As a result, plant capacity is not always fully utilized.

Fluctuating volumes

One of the primary challenges in measuring volume is that the amount of waste in recycling facilities fluctuates frequently. Waste is regularly delivered and transported back and forth between storage and plant areas. As a result, measured values become outdated quickly. Additionally, inaccurate unloading during multiple transports leads to inaccuracies in the measurement process.

Lack of documentation

Not only is the data on waste inventory insufficient and imprecise, but it is also often challenging for employees to locate. The values are typically documented in a mix of analog and digital processes, such as Excel spreadsheets, handwritten notes, and resource planning application systems. These values are not intuitively findable, making it challenging for employees to access the data they require.

Specialized 3D LiDAR technology can solve these problems. Operators of waste recovery and recycling plants now have access to exact data on material stocks at any time with little effort.

3 3D LiDAR-based volume monitoring

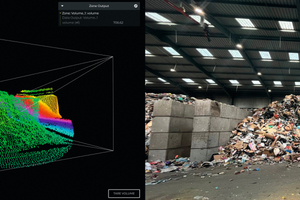

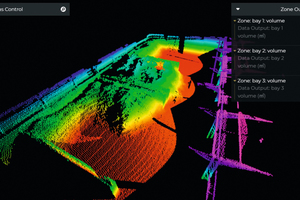

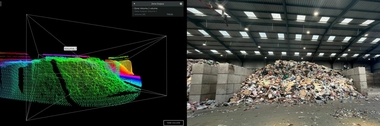

3D LiDAR solutions from Blickfeld use state-of-the-art laser technology to create a detailed three-dimensional image of the surface of waste piles and calculate their volume. The 3D LiDAR sensors emit hundreds of thousands of laser pulses per second over a wide field of view. When the laser light hits an object, in this case, the material surface of the waste pile, it is reflected and detected again. The distance to the object is measured from when the reflected laser light returns to the sensor (time-of-flight principle). This process creates a fine-grained virtual network of distance points over the entire material pile, from which Blickfeld‘s „Percept“ software solution calculates the volume precisely.

The Percept software can interpret the results of several sensors in combination so that even the volumes of vast stockpiles, common in the recycling industry, can be reliably and continuously recorded. If desired, the information can be automatically fed into the company‘s IT landscape, such as the software for material flow management or resource planning, and is immediately available for optimizing planning and operations. The latest 3D LiDAR solution from Blickfeld, the Smart Sensor Qb2, already integrates the software for data analysis into the LiDAR sensor device, eliminating the need for an external computer. This combination of hardware and software simplifies installation and use significantly.

4 A vital contribution to achieving the

circular economy

3D LiDAR sensor technology provides material data in recycling plants, enabling considerable process improvement in the recycling industry. The accurate knowledge of material inventory that 3D LiDAR provides is a game-changer for achieving a more comprehensive circular economy. For the first time, managers have access to reliable information on stock, which is a critical factor that can impact the entire recycling process, from delivery planning to processing at the plant to delivery of the manufactured recyclates. Thus, volume monitoring with 3D LiDAR holds high optimization potentials and can contribute significantly to developing closed resource cycles.

5 Case study: 3D LiDAR-based inventory management at Cireco

Cireco, one of the leading Scottish resource management companies, is an excellent example of how 3D LiDAR technology can be used for inventory management in recycling plants. Like all waste and recycling companies, Cireco must comply with a wide range of legislation and continually work to improve its processes and increase efficiency.

The initial situation

Previously, Cireco relied on truck weighing data and visual estimates from experienced employees to determine inventory levels, which were used to plan and control the utilization of the sorting machine. However, due to the frequent new deliveries and continuous waste movement between storage boxes and the sorting machine, the estimates often differed significantly from the actual quantity available for sorting. As a result, there was underutilization of storage and equipment capacity.

The decision for QuVo Limited and Blickfeld´s sensors

To address this issue, Cireco collaborated with volume measurement specialist QuVo Limited to implement an automated volume monitoring solution based on Blickfeld‘s 3D LiDAR sensors. The solution continuously captures 3D data of the waste piles and immediately calculates the material volume, with any change in stock immediately apparent. This solution provided Cireco with an accurate overview of the actual volume of waste stored in the boxes at all times, enabling better utilization of the recyclables recovery facility and compliance with material storage safety regulations more easily.

Three sensors offer sufficient coverage for

several boxes

To detect all the waste stored in the various boxes, Cireco mounted three Blickfeld Cube 1 LiDAR sensors on the hall ceiling. Thanks to the large field of view of these sensors, this small amount of sensors is sufficient to cover the large area across several boxes:

The LiDAR sensors continuously capture 3D data of the waste piles

The associated software immediately calculates the material volume, with any change in stock directly apparent

The implementation of this technology allowed Cireco to optimize inventory management and material flows, forecast resources in each box more accurately, and utilize more storage capacity, resulting in better planning, utilization, and control of the recovery facility. The company is also installing additional sensors at a second site, enabling inventory recording at multiple locations and analysis of the results, further improving efficiency and accounting accuracy across sites.

Overall, 3D LiDAR sensor technology for inventory management in recycling plants holds high optimization potentials and can contribute significantly to developing closed resource cycles, which is a critical step towards achieving a more comprehensive circular economy.

Author:

Dr. sc. Florian Petit, Mitgründer und CXO der Blickfeld GmbH, München/Deutschland

Literature

Features of the Smart LiDAR Qb2

• High range up to 100 meters

• Large field of view

• Low power consumption

• Flexibly customizable via software

• Works in darkness, rain, snow, and dusty air

• WiFi data transmission

• Data and power transmission over the same cable (Power-over-Ethernet)

• Easy installation

• Low maintenance