Metso provides tailor-made solutions for future requirements

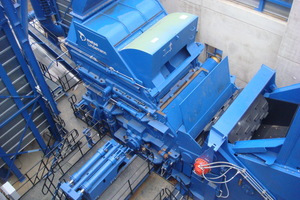

Plant design with pre-shredder provides advantages

In Metso’s plant technology for the first recycling stage, the material stream of end-of-life vehicles, bundles of scrapped car bodies, of household devices and light collected scrap is led to the pre-shredder. Its operating principle provides a series of advantages for downstream-arranged process steps of the shredder. In this preliminary stage, the supplied materials are homogenized. At the same time, the material stream is homogenized on its way to the shredder, which reduces load peaks and noticeably improves efficiency as well as the production rate of the unit. Heavy parts and contaminants are eliminated resulting in improved plant availability.

Increase in production through smart shredder control

The profitability and efficiency of a metal recycling shredder is of particular importance. Metso’s answer to this is the smart shredder control SDA (Shredder Drive Assistant). The control module optimizes the operating parameters of feeding and drive components and synchronizes them at the same time. The monitoring of the relevant process parameters ensures a continuously high throughput level. Customers using or retrofitting this technology achieved production increases at double-digit rates, says the manufacturer.

Solutions for the reduction of dust and

emissions

Metso, for many decades one of the leading shredder manufacturers and characterized by the Lindemann DNA in recycling technology, provides convincing solutions to enable the compliance with the current environmental standards. Metso technologies feature a modular design and are thus tailored to the needs of the customers at the respective plant location.

The Metso high-pressure water injection results in substantial dust reduction in the shredder room. The dust adheres to the generated water mist. The cooling of the shredder chamber thus achieved significantly improves the thermal situation; moreover, the water mist displaces the air in the housing. This reduces deflagrations and their consequences. Depending on the customer requirements, the remaining dust is transferred to a wet dust extraction system based on double Venturi washer technology or to a dry dust extraction system equipped with fabric filters.

With further modular system components, such as activated carbon filters, it is possible to increase the cleaning efficiency. In this regard, Metso is cooperating with the dust extraction experts from R&R Beth.