Non-ferrous metal separator for very fine materials

Fine-grain sorting materials have no chance of escaping when Galloo, one of Europe’s biggest recyclers and a pioneer in metal recycling, teams up with the Cologne-based sorting and separation specialist STEINERT.

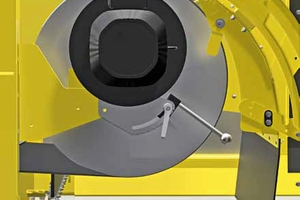

The two sector heavyweights have developeda new non-ferrous metals separator for finematerials. The new system’s splitter can be set withmillimetre precision, enabling non-ferrous metalssuch as aluminum, copper and zinc to be separatedmore effectively than ever before. Additionally, themachine was designed so a conveyor belt change canbe carried out in 10 minutes, without heavily liftingequipment or excessive downtime.

A non-ferrous metal separatorfor a variety of fine-grain materials

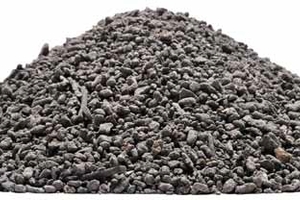

In 2013, Galloo wanted to expand and began toconduct studies into more efficient ways of extractingnon-ferrous metals from fine-grain material.Galloo contacted the engineers at STEINERT, askingthem to develop a flexible machine concept forthree different input materials: automobile shredderresidue (ASR), incineration bottom ash and electronicscrap.The challenge with this task is that the input is extremelyfine material, with grain sizes of 0.5 – 10 mm. Thegoal was to enable the three different materials to beto run through the system flexibly without any dropin the separation rate. Engineers wanted to furtheroptimize the separation of non-ferrous metals out ofthe fine-grain fraction and, at the same time, simplifythe machine’s operation and maintenance.STEINERT adapted the outputto the machine’s requirementsand developed a splitter that canhandle the three different typesof fine-grain material. Fine gearboxadjustments can be made tothe splitter to enable it to get towithin a few millimetres of the material, separatingeven the tiniest particles. The machines now run atGalloo in two shifts for a total of about 16 hoursper day. “We are now buying input material fromGermany, Denmark and the UK, because the systemruns so reliably,” said Galloo R&D Officer LucWaignein.

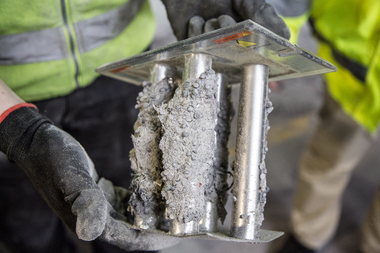

10-Minute belt changewith the STEINERT EddyC FINES

After the successful installation Galloo, STEINERT’sdevelopment and design team began to work onadditional features especially for the fine-grain sector,leading to the creation of the new STEINERTEddyC FINES. The STEINERT EddyC FINES has aframe structure which allows the belt to be replacedin 10 minutes. “Changing the belt of an eddy currentseparator often takes a company half a day, with up tothree employees and heavy lifting equipment neededto perform this task,” explains STEINERT TechnicalDirector Dr. Nico Schmalbein. With the STEINERTEddyC FINES, two employees can carry out a beltchange with nothing more elaborate than a spanner.The easy handling is a big benefit for Galloo. “Wenow need fewer personnel for belt changes and thereis less downtime,” says Luc Waignein

A STEINERT EddyC FINES in action in Belgium

At the same time, Galloo is building a new facilitythat will recover exclusively non-ferrous metalsfrom grate ash. The ash contains up to six percentiron and up to three percent non-ferrous metals.However, the particles are very small, measuringonly 0.5 – 4 mm. As a result of the previous goodexperience, Galloo is using the new developmentfrom STEINERT, the STEINERT EddyC FINESin the new facility.

A flexibly adjustable splitter

The new system’s splitter plate has to be preciselyadjusted in order to separate the metals from thefine incineration bottom ash material. “A gearboxnow enables users to set the splitter plate with millimetreprecision along three different axes and adjustit even more accurately to the parabolic trajectoriesof a wide variety of materials. In addition, a correspondingupgrade enables the program-controlledsystem to focus on predefined points of the parabolictrajectory,” says Schmalbein. “In combinationwith a continuously adjustable eccentric magneticpole drum, this system can achieve optimal separationresults.”This enhancement pays off for Galloo. “The new systemwill enable us to sort so many tons of incinerationbottom ash each year that even small improvementsin the separation rate will have a noticeablefinancial impact. We mainly recycle aluminium, copper,zinc and brass, as well as a few precious metalssuch as gold and silver,” explains Waignein. Besidesthe separated metals, the remaining metal-free mineralmixture is also valuable.

Without parallel on the market:The pole drum’s eccentric pole system with4000 rpm over a working width of 2 m

The non-ferrous metals separator has a rapidly rotatingmagnetic pole system that induces eddy currentsin the non-ferrous metals transported on the conveyorbelt. The resulting opposing magnetic field createsrepulsion effects, which enables the non-ferrousproduct to be ejected from the stream of material.The splitter plate in the parabolic trajectory separatesthe non-ferrous product from the remaining streamof material. “We made sure the splitter plate wasadjustable so that the system can react to a variety ofinput materials. Before we did this, we analysed theflight properties of various materials and used thisinformation to work on the settings,” says JochenSchäfer, a design engineer at STEINERT. “The splittercan be adjusted to specific trajectories in order toaccommodate a variety of separation tasks.”“There is nothing comparable on the market forconveyor belt widths of two metres,” says KarlHoffmann, Key Account Manager at STEINERT.The extremely high pole change frequency activateseven tiny particles measuring less than a millimetreso that they can be separated.

Partners are well prepared for the future

Waignein is delighted with the cooperation withSTEINERT. “Ten years ago, you could only obtainstandardized devices on the market. It was impossiblefor us to adapt them to our specific needs. That’s whywe are extremely happy that we and STEINERThave been able to jointly develop a system that preciselymeets our requirements.”Galloo has been cooperating with STEINERT since1985, when the recycler bought its first non-ferrousmetals separator. “We have always been impressedby the products’ quality. The machines just keep onrunning – some of them for 15 years now – and theyrequire little maintenance,” says Waignein. “Althoughthere are machines on the market that might seem tobe economical, they don’t benefit us if they only runreliably for a year and then cause expensive downtimes.”Today, most of Galloo’s non-ferrous metalsseparators and magnets come from STEINERT.Galloo is a special customer for STEINERT as well,because the recycler has provided the engineers at thedevelopment and design department with valuablefeedback for the past 31 years. “That’s why we decidedto draw on Galloo’s practical experience when weupdated the splitter in 2016. The large amounts offine-grain material prompted us to solve this problemand create a very profitable solution for our customer,”says Hoffmann. The result is a system that sorts finegrainmaterials even more reliably and economicallythan before. That’s why Hoffmann is certain that “ourcontinuous cooperation with customers such asGalloo and our ongoing research and developmentactivities make us a reliable and competent partner forcreating separation and sorting solutions.”A video showing the belt change, the new system’ssplitter and the plant in operation can be found at:

STEINERT EddyC FINES

-Application: Separation of non-ferrous metals(aluminium, copper, brass, etc.) for particlesmeasuring 0.5 – 10 mm in:

- Incineration bottom ash (waste incinerationash)

- Automobile shredder residue (ASR)

- Electronic waste

- PET flakes

- DrossXX Splitter adjustable with millimetre precisionXXBelts can be easily changed in approximately10 min

- Magnet: permanent (neodymium iron boronNdFeB N52), high-frequency rotating magnetsystem

- A neodymium magnet system that rotatesat high frequency (special eccentric magnetsystem) creates a strong magnetic eddy currentfield. The eddy current field is used todeflect and sort non-ferrous metals out of thestream of materials.

- Magnet rotor speed: 2610 – 4000 rpm

- Working width: 1000, 1500, 2000 mm

- Belt speed: 1–2.5 m/s