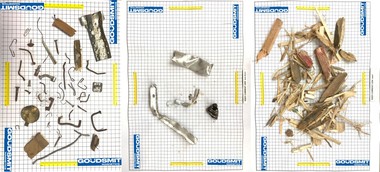

New classifier system for non-ferrous metals

“A classifier is generally defined as a device used to classify solid matters. Using the different sink rates of the various substances in an air stream, they are subdivided and separated according to defined criteria, as for example particle size, density or inertia,” explains Florian Boehm-Feigl, CTO at Erdwich. “One of our projects includes a classifier system for non-ferrous metal granulate.” This can be used to separate dust, pure granulate, foils, lint and other light materials made of non-ferrous metal. It is important to obtain the light material as reliably, simply and, above all, maintenance-free as possible in order to either further separate the non-ferrous metal or sell it afterwards. Special adjustments such as a throughput of up to 5 t/h or a wide variety of material mixtures such as aluminium, iron, copper and other non-ferrous metals as well as wood, plastics, fabric or dust make the system unique on the market. Moreover, the system can be used for all areas in which heavy material needs to be separated from lightweight material. However, the metal’s grain size must not exceed a diameter of 100 mm.

Classifier extends existing large-scale system

In the metal recycling sector, the classifier system, with a height of 7146 mm and a width of between 5616 mm and 7461 mm - depending on the position of the elevator support - can be used, for example, in combination with an RM 1350 twin-shaft shredder as a pre-shredder for non-ferrous scrap. With this, it is possible to monitor and control six different automatic program sequences: the control cabinets for granulator, magnet technology, non-ferrous separation technology and X-ray separation technology as well as the dust filter system and the RM 1350 pre-shredder. The separator plant thus enables the expansion of an existing large-scale system and is installed directly below the conveyor-belt discharge of a screen drum. By separating different materials, such as aluminium, copper or other metallic alloys, the material is dedusted and freed from foreign matters thus achieving significantly higher prices in resale.