New process for complete materials-route recycling of electroplating waste

The production of electroplated plastic components makes extremely high demands on the material‘s surfaces. Up to 30 % of production is out-of-specification. Up to now, there has been no process for the rational utilisation of this production waste. Clever combination of selective mechanical pre-treatment with melt filtration and the CreaSolv® Process developed at the Fraunhofer IVV in Freising now makes it possible to completely recycle this material flow and route it to a further product life-cycle.

1 Background situation

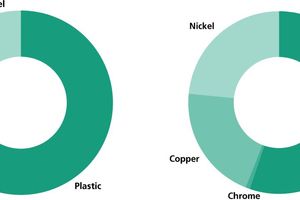

Electroplated, more commonly known as „chromed“, components are used in many fields of everyday life, including sanitary and hygiene installations (showerheads, faucets) and in the automotive sector (radiator grills, trim strips, door handles), for example. Thanks to their straightforward processability, low production costs and great design freedoms, plastic components are most often used as the underlying basis for such decorative and, at the same time, corrosion-resistant metal surfaces. Such polymer materials must firstly be made electrically conductive by a chemical pre-treatment before they can be electroplated. A coating of copper is then firstly applied by a number of electrolytic processes, followed as the procedure continues by the application of a layer of nickel and, ultimately, a layer of chromium, thus producing the highly reflective metallic surface. Such components will typically have a plastics content of around 80 wt % after electroplating.

Faults can occur in coating at various process stages in the production of electroplated surfaces and subsequently become apparent in the form of blisters or pimples. These production flaws are generally the result of inadequate plating adhesion. Such components are rejected during the quality control process, since such surface blemishes cannot be retrospectively corrected. This rejection rate is, in practice, above 10 %. Rejection rates of 25 to 30 % are, in fact, customary in the case of electroplated polyamides. The result of all this is that more than 1600 t of production waste was generated by eight of Germany‘s twelve largest producers of electroplated plastic components 2015, and around 1300 t in 2016.

Materials-route recycling of this waste is difficult using the current state-of-the-art technology. Corresponding recycling concepts focus either on the plastic or on the metal content - there is no recovery of both fractions. Rational and exhaustive exploitation of the whole recyclables potential is possible despite the unequal distribution of the components by mass in electroplated components only if both fractions, i.e., the plastics and the metals, are recycled, however (Figure 1).

An innovative recycling method has been developed by the Fraunhofer Institute for Process Engineering and Packaging IVV, Freising, under the auspices of the ForCYCLE project alliance funded by the Bavarian State Ministry of the Environment and Consumer Protection, in order to tackle this challenge and reduce the volumes of waste yielded by electroplating plants. Intensive cooperation with a number of industrial partners in the fields of plastics processing, recycling/compounding and mechanical recycling has made it possible to implement and evaluate this process on an industrially rational scale.

2 The process

2.1 Overview

The process developed consists essentially of three operations [1]: selective shredding of the sorted components with integrated removal of metals, extrusion of the plastics fraction, with integrated melt filtration, and the CreaSolv® Process, developed at the Fraunhofer IVV for recovery of the residual polymer from the melt filter cake (Figure 2). The electroplating waste needed for this purpose was provided by WAFA GmbH, Augsburg, and then shredded and classified by Hosokawa Alpine AG, Augsburg. Tests into melt filtration were conducted at Sysplast GmbH & Co. KG, Nuremberg. The use of the CreaSolv® Process for extraction of polymers from the metal concentrate was investigated at the Fraunhofer IVV.

2.2 Selective shredding

Project partner WAFA supplied approx. 1 t of electroplating waste from the automotive sector as test material. This batch consisted of acrylonitrile butadiene styrene (ABS) (78.0 wt %), metal-plated with a coating system consisting of copper (13.5 wt %), nickel (8.1 wt %) and chromium (0.4 wt %) and had already been pre-shredded to < 50 mm in a granulator mill. Initial laboratory tests using a cross-beater mill demonstrated that impact loading and temperature profile exert direct influence on material separation. These findings were then used for upscaling of the process to commercial scale in an impact mill in cooperation with project partner Hosokawa Alpine, while grinding and demetallisation were further optimised. The particle-size distribution of the grinding stock and the metal contents of the fractions were defined as quality criteria. The effects of product temperature and mill speed were also investigated during the optimisation process.

A Type UPZ 315 fine impact mill was used for these tests. It became apparent that processing under cryogenic conditions resulted in improved metal/plastic separation, but also in a higher fine-particles fraction (< 2.0 mm). Variation of mill speed demonstrated that high impact velocities promote material separation. This is the result, inter alia, of the then greater shear loading acting between the polymer and the layer of metal. An optimum combination of composite separation, operating costs, particle-size distribution and yield was attained at room temperature and a fine impact mill speed of 3500 rpm.

2.3 Melt filtration and re-electroplating

After selective shredding and dedusting, the plastic fraction was fed to an extruder equipped with a continuous high-capacity melt filter. Such melt filters can normally be operated at a maximum metal content in the feed of 10 wt %. Where metal contents are higher, the material must be mixed with virgin plastic in order to assure adequate filter service-life and to reduce the input of thermal energy acting during extrusion on the polymer melt as a result of shearing of the metal particles.

The upstream reduction of the metal content in the plastics fraction from 20 to < 8 wt % which takes place in this process made it possible to dispense with the addition of new plastic material and to remove all residual metals of a particle size of > 100 µm from the feed flow entirely. The filter residue took the form of metal concentrate, embedded in a porous matrix of plastic and with a polymer content of 15 to 25 wt %. The quality of the recovered regranulate in terms of its mechanical characteristics was then investigated.

The ABS regranulate (referred to below as rABS) achieves excellent scores when compared against new material. The only moderate reduction observed in its impact strength can be counteracted using additives if necessary. A polymer blend with polycarbonate (PC) was also prepared in order to open up further sale routes for the rABS. The mechanical characteristics of this compound are at the same level as those of virgin PC/ABS material.

In addition to the retention of mechanical characteristics, this project was also to demonstrate that this rABS can be reused for electroplating. Five samples of material were prepared for this purpose:

10 wt % rABS + 90 wt % new ABS material

30 wt % rABS + 70 wt % new ABS material

50 wt % rABS + 50 wt % new ABS material

100 wt % rABS

100 wt % PC/rABS

These material samples were used for the production of injection mouldings, which were then submitted to renewed electroplating at project partner WAFA. The resultant material surfaces were then examined both visually and by means of qualitative tests. The surface properties of all the product samples produced were categorised as „good“ (Figure 3). Smaller isolated inclusions on the otherwise smooth metal layer were observed only in the case of the sample of pure rABS, and were attributable to residual traces of metals in the polymer matrix. All the product samples prepared underwent laboratory testing for adhesion, temperature cycle and corrosion properties (the „CAAS“ test), and achieved excellent results. It was thus possible to document the suitability of the rABS material for use in a further product life-cycle in electroplating components.

2.4 Preparation of the metal concentrate from melt filtration using the CreaSolv® process

The CreaSolv® Process uses special CreaSolv® Formulations with the lowest possible potential risks for users and the environment (ideally, substances not subject to mandatory marking on globally harmonised system [GHS] criteria), in order to selectively isolate a target polymer from a composite and thus separate it from extraneous materials [2]. A CreaSolv® Formulation selective for ABS was used in this processing stage in order to isolate the remaining 15 to 25 wt % of the polymer from the metal concentrate and thus also recover the plastic from this sidestream.

X-ray fluorescence analysis was used to show that the extracted plastic has only a negligible chromium content and only extremely low nickel (< 1000 ppm) and copper (around 3000 ppm) contents. The mechanical characteristics of the ABS recyclate obtained from the CreaSolv® Process were not, equivalent those of new material; this material can, however, nonetheless be fed to melt filtration as an additive, or used as a start-up material, and thus rationally recycled.

It was possible to prepare the metallic, polymer-free residue from the CreaSolv® Process using hydrometallurgical methods. A chromium content of < 1 wt % was the precondition for this. It was demonstrated in the laboratory that single-stage scrubbing using hydrochloric acid achieved reduction of the chromium content down to 0.3 wt %. Subsequent preparation of nickel and copper is state-of-the-art and was performed and evaluated by external partners for the purposes of this project. Quality evaluation was conducted on the basis of repurchase price, which was calculated by commercial metallurgical companies for the respective product samples.

3 Economic evaluation of the process

As mentioned above, significantly more than 1000 t of electroplating waste is yielded annually in Germany from industrial production processes. A business case for the recycling of this flow of material from the viewpoint of a waste recycling organisation was drafted on the basis of this yield and the recycling process developed in the context of the ForCYCLE project [1]. This analysis compared the value of the materials recovered plus the non-expended disposal costs against the investment and operating costs of the process and the costs of purchasing material (Figure 4, left). The materials data for the metal fractions was determined in cooperation with external metallurgical companies. The costs for mechanical pre-treatment were borne by Hosokawa Alpine, taking account of equipment wear and tear and a depreciation period of ten years.

It is apparent that the process would reach its break-even point at a throughput rate of 500 tonnes per annum (Figure 4, right). Recycling of production waste as an „in-house solution“ would be an economic proposition for manufacturers with this or a greater yield of waste annually. Even greater cost-savings, or system profitability on smaller scales of operation, would also be conceivable, since new plastic material could, in this case, be replaced directly with recyclate, making it possible to assume significantly lower costs for materials purchasing.

4 Conclusion

A process for the recovery of recyclables from electroplated plastic waste has been developed via the combination of three technologies under the auspices of the ForCYCLE joint project. Here, selective shredding with integrated metal removal, melt filtration and the CreaSolv® Process are used in order to recycle the waste feed almost completely. The products of this process can, to a very large extent, be reused for their original purposes, and can thus be returned to a further product life-cycle.

It has proven possible to optimise the process by means of modification of the individual operations to an extent sufficient to permit system profitability as from a waste flow of 500 tonnes per year. This process would therefore also be of interest to producers of electroplated plastic components, and not only to recycling organisations. Costs, and also the generation of waste during the production process, could thus both be significantly reduced - another step toward the attainment of the „circular economy“, with closed materials cycles.

Acknowledgements

This work was funded by the Bavarian State Ministry of the Environment and Consumer Protection (Funding Code: BAF 01SoFo-65342). The authors wish to express their gratitude to all project partners involved in the ForCYCLE project alliance. Particular mention should be made here of the members of the „Hybrid materials“ subproject named in the article.

![Figure 2: Process diagram of the recycling process developed for electroplating waste [1]](https://www.recovery-worldwide.com/imgs/1/2/9/7/5/5/3/tok_32fdb45e1d44ba2e7c4f7c728b9ef052/w300_h200_x600_y458_Bild_2-af87116a8e5e09f5.jpeg)

![Figure 4: Cost-efficiency observation of a recycling process for electroplating waste: make-up of total costs (left) and comparison of income (right) [1]](https://www.recovery-worldwide.com/imgs/1/2/9/7/5/5/3/tok_513229a5a1d0f4d36a72882fd8342da2/w300_h200_x600_y291_Bild_4-c11adacd5947b2e5.jpeg)