New processing plant for garden waste

An intriguing story: In 1882, a group of farmers from the West of England got together, chartered a train, loaded it with all their cows, sheep, horses and agricultural equipment, and set off eastwards. Due to the agricultural recession caused by cheap products from the British Empire, farmers were needed in other rural areas, such as Sussex. This pioneering undertaking simultaneously marked the birth of the The Woodhorn Group.

This, even now, remains a (fourth-generation) family-managed company – headed by John Pitts. Even today, its centrepiece is its 1500 hectare organic farm, with its dairy centre, spreading across the Chichester Plain and the South Downs.

The Woodhorn Group‘s scope of business has expanded since the company‘s foundation, however. Since 1998, the group has successfully entered the green waste recycling segment. Three recycling centers, located at Tangmere, Runcton and Hayling Island and with a licensed capacity totalling 108,000 t/a, are operated by the company, processing local garden, wood and vegetable waste from the foodstuffs sector – from supermarkets, for example. The products, such as 100 % peat-free garden soils, soil conditioners, bark mulch, green-roof substrates and composts, are then marketed under the „Earth Cycle“ brand. „Here at Earth Cycle, our view is that gardening and horticulture should focus not only on results that look great, but also on doing something good for the environment. This is why all our products are 100 % peat-free and made exclusively from vegetable materials originating from our region,“ is the Woodhorn Group‘s corporate philosophy.

One of the three recycling plants is situated in the municipality of Tangmere. Here, since 1998, green waste has been converted to high-quality compost, which is then used as the feed material for the individual garden soils and other products. In 2012, this plant processed 30 000 t of green waste; this figure has now risen to 52 000 t/a. Despite continuous optimisation of the production process, the plant‘s management team recognised that they had reached the technological limits of the facility – and customers‘ expectations in terms of quality and the composition of the composts and soils had also changed with time. The serviceability of a number of system components also appeared to have reached its end. Screening, for example, had previously been accomplished using two mobile screening drums. New investments were vital, but it was also necessary to locate plant equipment which would meet the increased demands – simple replacement of the existing machinery was not an option. So a team consisting of Cameron Lewis, General Manager of the Woodhorn Group, Raimonds Mamonovs, Site Operations Manager at the Tangmere Composting Facility, and Morgan Davies, Waste and Recycling Manager, set out on a quest, visited reference facilities, and also continued to include still rising volumes in the conception of a new plant.

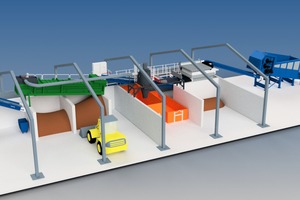

Since Komptech equipment had already been in successful use, the Austrian technology supplier‘s representatives passed on the useful tip of using a stationary screen – Multistar 2-SE star screen technology – as the core element. Since this was to be an investment in a completely new preparation line, there was much to be taken into account, tested and adapted to on-site circumstances. The advantages of a star screen were to be found in its high capacity and high selectivity, signifying that even future increases in production volumes would cause no problems. One of the two Maxx-type screening drums was also to continue in use. The air classifier and the entire feed system, on the other hand, were to be reconceived and redesigned. The new investment was, for the search team, by no means a snap decision – there were many questions and details concerning the technical equipment, the required operating data and, of course, the financing of the new processing plant, which needed to be clarified.

Visits were made to a number of Komptech reference installations in various countries. The team spent much time in Germany, where the star screen is produced, discussing the exact type and the options available for the new equipment. At the end of this long road, the Woodhorn team had gained a precise vision of its future plant, which it then put into practice together with Komptech‘s marketing associates in the UK, Hanlon-Komptech Great Britain.

Multistar 2-SE

Komptech‘s star screen technology is one of the most productive separation methods in the field of processing of organic waste. Precise selectivity, irrespective of feed moisture content, and modification of the particle-size range produced at the push of a button, are important features of Multistar star screens.

The Multistar 2-SE star screen system‘s compact design makes it an easy-to-integrate solution. Its modular structure, along with options such as sub-frames, a feed-metering hopper complete with feed and extraction belts, air classifying, etc., all assure spot-on meeting of customers‘ wishes.

Maxx

Komptech‘s Maxx mechanical screening drum was conceived for use in medium-scale and large composting plants. Its robust structure and high-performance components make it suitable for practically any screening application, and thus the professional solution for agricultural contractors.