Recovery of phosphorus – potentials for a technical and commercial solution?

The „Circular Economy“ workgroup (WG CE) of the CLEANTEC Initiative Ostdeutschland (CIO) held its kick-off event on the interesting topic complex of phosphorus recovery at the University of Leipzig on 18 May 2017. CLEANTEC is an initiative of the federal government‘s commissioners for the eastern German federal states.

An interesting agenda, which threw light not only on the legal and scientific, but also on the practical technical and economic sides of the field of topics, awaited the around fifty attendees. Dr. Eberhard Kiez, of the Saxon Ministry of the Environment and Agriculture, Dresden, for example, outlined the boundary conditions for the recovery of P, focussing on his federal state. In line with the targets set by the federal government, soil-related use of sewage sludge is to be discontinued, and phosphorus to be recovered from this sludge. Dr. Kiez examined both the amended AbfKläV and the amended DüV and the consequences of the new requirements on the higher necessary funds, which are to be provided from waste-water charges. His credo: treatment-plant operators must begin acting even now.

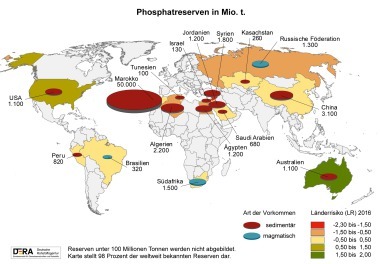

Prof. Dr. rer. nat. habil. Martin Bertau, of the TU Bergakademie Freiberg University of Resources, chairman of the WG CE, also included current trends in research and science in his excellent overview paper on the state-of-the-art in the recovery of P. His guiding concept: recycling of P must not become an end in itself - the lesson from the energy turnaround must be learnt: cost-efficiency is the prime concern. The motivations for recycling are readily apparent, however: in addition to the geopolitical uncertainties surrounding mineral-resources supplies (and classification of apatite as a critical resource) and also the legal requirements, there are, in addition, the ever greater heavy-metal contents, particularly of Cd and U, found in the deposits, and the finite nature of landfill capacity. There is currently no cost-efficient process for the production of fertilisers or phosphoric acid from SSA, however. There are, at present, 67 process concepts, focussing on fertilisers and struvite (NH4 MgPO4), however. All of these routes manifest one or more deficits, however, with the result that it is not possible to present a viable overall concept. More recent deliberations based on investigations of ash chemistry do indicate the potential for the recovery of P from SSA. Six further-refined processes (SeraPlant, TetraPhos, PRiL, PYREG, ExtraPhos and PARFORCE), for which pilot plants are already at the planning stage and (in the case of PARFORCE) a demonstration plant with a throughput of 1 t/d of SSA under construction, result from these investigations, and were discussed at the conference.

Dr. rer. nat. Peter Fröhlich, also of the TU Bergakademie Freiberg University of Resources, reported in detail on his own experience with the above-mentioned PARFORCE process. This is a wet-chemical procedure suitable for use with various feed materials and consists of the processing operations of digesting using acid (HCl or HNO3), filtration of the digestion suspension, extraction of the phosphoric acid formed by means of monoselective electrodialysis, and concentration of the H3PO4 by means of evaporation. Benefits result for the dephosphorisation of the SSL at the sewage treatment plant thanks to struvite precipitation using MgCl2. Costs differ greatly depending on the feed material, the product being an extremely pure, universally useable H3PO4, which does not suffice to make the process cost-effective, however. It has therefore been further developed to permit complete valorisation of all products. A further advantage of this process is its modular structure, incorporating core components and standard process stages. A partnership network with industrial partners is currently being set up and an overall concept which can be integrated into existing processes is being provided for treatment-plant operators. Individual technologies are either undergoing industrial-scale testing or are already in use.

Technical and commercial solutions also appear realistic for other process developments now undergoing tests in pilot plants, however. These include, for example, the so-called ExtraPhos or Budenheim process, which was examined by Ulrich Kotzbauer, of ROTARIA Energie- und Umwelttechnik GmbH, of Rerik. Here, CO2 is fed at 10 bar into wet digester sludge in a tubular reactor for 15 min. and the CO2 recovered via an expansion tank. The treated sludge is separated in a centrifuge into a P-depleted thickened sludge and a filtrate. The latter is then mixed with milk of lime. Dicalcium phosphate, also known as calcium monohydrogen phosphate, easily accessible for plants, is then obtained in settling tanks. This speaker mentioned the recycling of the CO2, the use of non-hazardous chemicals (CO2), the lack of need for heat for the process cycle and the direct possibility for agricultural use as special benefits of this route. The pilot plant is located at the Mainz-Mombach sewage treatment plant, with draft planning and the start of construction of the first commercial-scale facility for recovery of P planned for 2018 at the Itzehoe sewage treatment plant.

Dr. Matthias Staub, of TVF Waste Solution GmbH, Boxberg, was already able to report on the Veolia group‘s more extensive experience in the recovery of P. Two routes were examined: recovery of P a) from SSL (plants in Braunschweig and Helsingør) and b) from SSA. The latter route requires mono-incineration installations, however, and is practised, in particular, in France, eastern Europe and Turkey. Analysis of the question of „recovery of P from sewage sludge or from ash?“ must take account of the fact that the construction of a dedicated mono-incineration facility for sewage treatment plants of between 50 000 and 500 000 PE is not rational, thus excluding around 25 % of the German market. Veolia continues to favour a combination of processes. The so-called STRUVIA™ process has already been tested on a commercial scale and is currently undergoing optimisation for attainment of targets of > 50 % recovery and reduction of the use of chemicals. Research emphases are currently also on the fields of ash recycling and the marketing of the fertilisers; corresponding results are anticipated in 2018 – 2019.

Dr. Christian Krabbe, of the Berlin Centre of Competence for Water (KWB) Berlin gGmbH, viewed the recovery of P from SSL extremely critically, and predicted that it will not, alone, be capable of achieving cost-efficiency in the next fifty years. As he noted, value chains must be set up to achieve genuine recycling, both for recovery from the liquid phase and via thermal processes (product of P4 by means of thermolytic reduction), and that many uncertainties remain to be eliminated - the EC directive for the use of struvite for organic farming must also still be updated, for example. The legislator‘s demand for the recovery of P is also somewhat half-hearted, since it does not extend to the valorisation of the recyclates!

Dr. Krabbe‘s rather pessimistic conclusion: recycling of P will continue to be a „hobby“ occupation, only mono-incineration is a proven process, and responsibility for disposal will thus still be imposed on the treatment-plant operators.

The deliberations of Dipl.-Chem. Karin Jacob-Seifert, who discussed the recovery of P from pharmaceuticals waste-water, were more optimistic, however. Around 2 000 t of waste-water, with a phosphate content of 60 g/l had been analysed, and Ca3(PO4)2 produced from it by means of precipitation. The process, which employs relatively simple equipment technology, delivers a saleable product and, at the same time, „clean“ waste-water. Disposal of this effluent has, up to now, cost 89 €/t, whereas this process permits treatment costs of 45 €/t when product sales are included, thus demonstrating its commercial viability.

Monika Hentze, of Dresden‘s Stadtentwässerung Dresden GmbH drainage utility, impressively illustrated the challenges presented to treatment-plant operators by recovery of P from SSL, citing the example of the Kaditz sewage treatment plant (787 000 PE). In addition to adherence with certainty to all discharge limits and the P-recycling rate, as well as assurance of SSL disposal and of all subsidiary products, it is, above all, the commercial-scale maturity of the recycling process selected, with implementation scheduled for 2029/2032, which will, taking account of cost-efficiency, burden the operators.

Following the series of addresses, other companies and institutions had the opportunity of briefly showcasing their activities: the German Federal Environmental Foundation (DBU), for example, Europe‘s largest environmental organisation, the Helmholtz Institute Freiberg for Resource Technology (HIF), Poll Umwelt- und Verfahrenstechnik GmbH, Selm, and the internationally active Isle Utilities (Waste-) Water Innovation Consultancy.

Résumé

Both the organisers and the participants showed great satisfaction at the conclusion of the event. Interchange between the various companies and between the companies and scientists had been facilitated and had been intensively used. The subject of the recovery of P is of great topicality. Good concepts for the commercial implementation of corresponding process developments were outlined, without euphoria, but attention was also drawn to the associated problems. Further events are planned, initially taking a six-monthly interval as a basis. Mineral-resources topics - focussing both on primary and secondary resources - are to be brought more closely into focus, and holistic solutions sought. This kick-off event showed how the potentials of networking can be utilised under the auspices of CLEANTEC and the task now is to further elaborate the subject examined and to take up new topics, on the criterion, at all times, of informing and networking the industrial partners.

To be continued

The correctness of the résumé could not be better affirmed than by a second event on the same complex of subjects. This meeting was held in Freiberg on 6 February 2018 and was just as well attended as the first conference. Updated and new material from science, research and industry was presented and discussed, and illustrated the many and diverse activities which had taken place during the past year in the field of phosphorus recovery. Sebastian Strebe, IPU Dr. Born – Dr. Ermel GmbH, Dresden (Freital), for example, reported on the planning and construction of a thermal sewage-sludge utilisation plant on the island of Rügen. This plant was completed within the short construction period of two years in the vicinity of the Bergen sewage treatment plant as a self-contained solution, on the island and for the island, for the 38 sewage treatment plants operating on Rügen. It is a relatively small facility, with a throughput of 2500 tTR/a and investment costs totalling some 12 million €. The plant concept takes the form of a combined sludge-treatment process incorporating sludge digestion, with a gas storage facility, sludge dewatering and drying, thermal sludge treatment in a stationary fluidised bed, waste-gas clean-up using a quasi-dry process, energy utilisation (Digester gas → Power, Heat → Drying of sewage sludge) and residues recycling (Ash → P recovery). Sewage-sludge incineration is prioritised as a pre-treatment stage for the sewage sludge, since phosphorus can be effectively recycled from the resulting ash.

Dr. Christian Krabbe, of KZW Berlin gGmbH, also brought the audience up to date in his paper titled „Recovery of P - what‘s new?“. His conclusion from a renewed assessment of the various sewage-sludge treatment and P-recovery processes is: only those technologies which produce homogeneous and legally conformant product qualities, irrespective of the input material, and are also both energy- and resources-efficient, will find more widespread use, and may be considered to be sustainable. Also of importance is the obtainment of product status for the materials recovered, since only then - always presupposing utilisation - will it be possible to speak of genuine recycling. Prof. Martin Bertau, of TU Bergakademie Freiberg University of Resources, underlined this condition, and also outlined a potential for byproduct recycling in the recovery of phosphorus/phosphates from sewage sludges: the production of geopolymers. These inorganic macromolecules based on aluminosilicates can be recovered from silicate byproducts such as are yielded, for example, in the PARFORCE process, and then used as alternative binders. The use of sewage-sludge ashes generates inosilicates, which are also capable of incorporating into the aluminosilicate structure and fixing arsenic or chromium ions. The advantages possessed by the geopolymers are their temperature and thermal stability, their resistance to chemicals, their rapid curing, and their high ultimate strengths. They thus offer significant ecological and economic benefits: avoidance of landfill dumping, secondary utilisation with increase in value, utilisation of ash, slags, meals and inferior primary resources. They also have a broad range of applications and are a recyclable end product.

The sewage-sludge concept of the JenaWasser water authority and the eastern Thuringian authorities was examined by Dipl.-Ing. Sandra Michael, of the Stadtwerke Jena GmbH municipal utility. In-line with the legislator‘s stipulations, various concepts are being pursued for the recovery of phosphorus: a decentralised concept at the Jena Central Sewage Treatment Plant location, and a centralised concept envisaging the cooperation of all Thuringian, and of not less than the eastern Thuringian, authorities. This speaker‘s conclusion was that there are still many unresolved questions, and that treatment-plant operators are confronted by great challenges.

Marius Stöckmann, of EurA AG Ellwangen, Zella-Mehlis branch, focused in his paper entitled „Sewage-sludge valorisation – Potentials for the regenerative energy source, methanol“, on the unused resource of CO2 from biomass CHP plants. He showed that carbon dioxide from CHP plant units can be utilised, and the business models available for this. More will be reported later. Dr. Maximilian Hempel, of the German Federal Environmental Foundation (DBU), Osnabrück discussed this foundation‘s funding programmes for valorisation of from sewage-sludge byproducts and provided information on individual projects on this range of topics which are currently being financially supported.

Dr. Peter Fröhlich, of PARFORCE Engineering & Consulting GmbH, Freiberg, examined flexible PARFORCE technology, on which an article in recovery is planned in the next time. The event‘s attendees had an opportunity of visiting the corresponding demonstration plant.

The second working meeting also demonstrated just how important informative interchange between the participating players is, particularly during the transitional period up to the coming into effect of the various legal provisions. Some of the routes conceived have proven not to be feasible, while others have been further refined and new processes developed. Primary ores currently still remain available for fertiliser production, but prices are unstable and the procurement risk should not be dismissed; the costs of disposal of sewage sludge are rising, and the legal requirement for the recovery of phosphorus from sewage sludge is looming ever closer. An initiative such as this from CLEANTEC can therefore only be welcomed, since it provides a realistic opportunity for the formation and use of networks. Special thanks to the organisers for this, in particular.