Recycling at Carcoustics in Genk

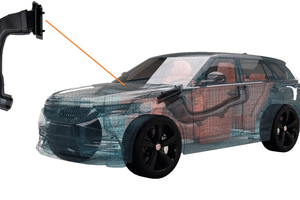

Carcoustics, a medium-sized automotive supplier, is specialized in thermal, acoustical and electromagnetic insulation of vehicles. Its‘ production plant in Genk/Belgium is experienced in Foam Air Ducts for years. This product optimizes the interior of a vehicle regarding air distribution, absorption and heat insulation.

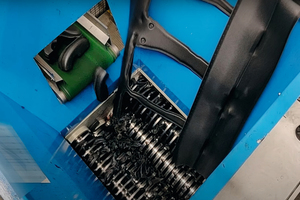

Within the process, closed cell, chemically or physically cross-linked polyethylene foam from 70 to 125 kg bulk density is formed into the special air duct form by the use of vacuum forming technology. The product is then stamped out of the material mat which leaves a certain amount of foam unused. To avoid waste and strengthen the recycling of materials, Carcoustics cooperates with the company Schmitz Foam Recycling.

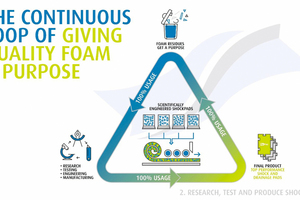

Schmitz has over 30 years of experience in the collection, removal and processing of foam scraps and has become the largest processor of these scraps in the world.

Via a transport system that was especially developed for this purpose, the foam residues are directly extracted into a waiting container. After being picked up by Schmitz, the shredded foam is the key material to produce artificial grass underlays for sports fields or children’s playgrounds. The foam underlay thereby works as a shock absorbing and drainage solution being the perfect base for high-quality artificial grass sports surfaces or provides the necessary fall protection in a children’s playground.

By this process, high quality materials are not only given a second life. Additionally, Carcoustics can completely avoid its waste from vacuum forming processes.