Recycling expert OZO uses mobile electrical solution in hall operation

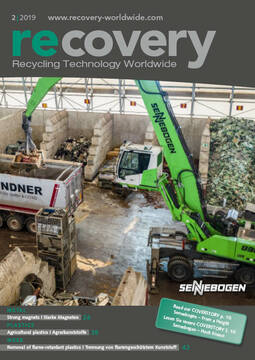

Without exception, vehicles painted green on the 9-hectare premises of OZO Ostrava s.r.o. – you might think you are in the middle of the production areas of SENNEBOGEN itself. However, there is only one SENNEBOGEN machine hidden in the halls of the recycling – a special machine that fits seamlessly into the newly created processes on site. The mobile electric material handler fills a RDF plant with pre-sorted thermoplastic waste from regional sorting lines in a 30-second work cycle. It is particularly important here that the driver can control different viewing heights at the workplace: whether aligned with the hopper to be filled or with small parts on the floor, the flexible cab elevation was an essential component in the choice of machine.

„In the long term, we also wanted to sustainably increase our production capacity. That is why we decided to build a completely new line. For us, however, sustainability is not just a key word when it comes to economic success. As a regional recycler, we also bear responsibility for the population and must set a good example,“ says Vladimíra Karasová, PR Manager at OZO, about the company‘s decision to use an electric material handler that guarantees low-emission operation. „We were also very satisfied with the counseling from our SENNEBOGEN contact person and look forward to further cooperation,“ says Karasová about the project implementation by the Czech dealer Merimex, who initiated and implemented the project in Ostrava.