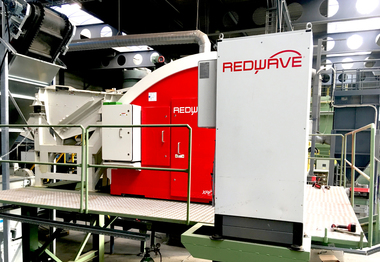

REDWAVE XRF fine setting new standards in performance and precision

REDWAVE, one of the world leaders in XRF sensor-based sorting technology, has introduced the next generation of sorting machines. The cutting-edge REDWAVE XRF fine sorting machine sets new benchmarks for sorting fine materials in the metal recycling industry. It can accurately detect and sort a blend of non-ferrous metals starting from a size of 4 mm, to produce high-quality products such as pure copper, brass, zinc and precious metal fractions.

Starting point

Metal recycling offers a multitude of benefits, including significant energy savings, while preserving valuable resources. For metal recyclers, fully automated sorting with X-ray fluorescence technology has proven to be extremely economical and efficient for years.

However, there is a challenge when it comes to sorting fine materials (4 – 25 mm) without any loss. Conventional sorting machines typically use a chute system, which works well for coarse materials, but presents certain drawbacks when handling fine materials. These include chute behavior, changes in trajectory, and the adherence of contaminated parts. These limitations can result in quality deterioration in the sorted material as well as a reduction in the output.

The new generation of XRF sorting technology for fine metals

REDWAVE has introduced an innovative solution for sorting fine metals with the launch of the trailblazing REDWAVE XRF fine. Developed specifically for materials measuring from 4 mm, the machine employs a unique belt system instead of a chute system, drawing on the company‘s extensive experience and cross-application know-how. Compared to conventional chute systems, the belt system boasts maximum precision. This is particularly advantageous when sorting fine metals, as they can be precisely identified and accurately ejected. The belt system offers significant benefits over the chute system when handling fine, small, and round materials (see table).

Designed with ease of maintenance and accessibility in mind, the new sorter has been optimised for rapid service and maintenance work. The belt change can now be carried out very quickly. The REDWAVE XRF fine machine is loaded with a significant increase in the number of energy-saving valves optimally arranged and spaced to maximise sorting accuracy.

The machine also boasts an innovative and highly developed sensor technology that offers fast scan rates, a higher resolution, and precise material detection. Additionally, REDWAVE is independent of supply chains. Thanks to these developments, the REDWAVE XRF fine sorting machine can efficiently sort fine material ranging from approximately 4 – 25 mm in size, setting new standards in performance and precision for metal recycling.

Is it profitable to sort fine metal using XRF sorting technology?

Currently, mixed fractions of fine scrap metal are typically shipped to Asian countries. Metal recyclers could achieve significant economic benefits by separating both common metals and precious metals from the mixed fraction and selling them individually at a much higher price. By using sensor-based sorting machines that rely on X-ray fluorescence (XRF), pure metal can be automatically and efficiently sorted on a large scale.

Sorting materials with XRF sorting machines and recovering metals from industrial waste incineration (IBA slag), scrap cars, or other non-ferrous metals efficiently increases the value of metals and pays off. The high-tech XRF sorting system can achieve a return on investment (ROI) within a short period of time.

The REDWAVE XRF fine has received overwhelmingly positive feedback from the market. This XRF belt machine has already demonstrated its immense potential and impressive sorting capabilities during tests at the REDWAVE test center. Customers have confirmed the machine‘s exceptional performance.

Trends and outlook

The current high demand for metals on a global scale, coupled with continually increasing metal prices, has resulted in a positive impact on the profitability of metal recycling. As a result, interest in XRF sorting technology has surged, further boosting the attractiveness of metal recycling and bolstering the profits of metal recyclers. Overall, XRF sorting technology provides a highly effective and precise method for analysing and sorting metal waste and scrap metals within the recycling industry. Companies that utilise this technology can enhance the efficiency, quality, and cost-effectiveness of their recycling processes, while making a valuable contribution to environmental protection.

“This innovation represents a significant breakthrough for the recycling industry. The technology promises to unlock new opportunities for metal recyclers across the globe to more effectively conserve and recover valuable resources, ultimately benefiting both their business and the environment,” says REDWAVE CEO Silvia Schweiger-Fuchs. By introducing this new sorting technology, REDWAVE has elevated metal recycling to a higher level, optimising the profitability of the entire process. Through the efficient sorting of fine materials, the technology ensures that the end products are of a higher quality, with fewer impurities. This leads to a more effective recycling of metals and results in higher prices for metal recyclers.

Take a look at the video here:

Author: Mag. (FH) Angela Thaller