Starlinger and PET to PET boost PET recycling in Austria

The Austrian recycler ‘PET to PET Recycling Österreich GmbH’ recorded a plus of 9 % in the recycling of PET bottles in 2018. With the growing demand for recycled material, the required capacity of the PET recycling line is increasing as well: Together with manufacturer Starlinger recycling technology, the output has recently been raised by 20 %.

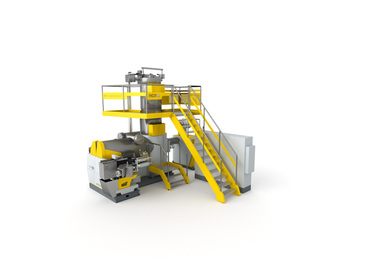

Since 2010, PET to PET operates a Starlinger recycling line of the type recoSTAR PET 125 HC iV+. With this line, the pre-cut, washed and sorted flakes are processed into high-quality regranulate. “With Starlinger’s technology, we have chosen one of the safest methods that guarantees thorough decontamination of the material according to the FIFO principle,” says Christian Strasser, Managing Director of PET to PET. “In this regard, the strict requirements of our owners, especially Coca-Cola, greatly influenced our decision when purchasing the line.” Geographical proximity – Starlinger and PET to PET are only about 30 miles apart – also played a role, as it allows short-term spare parts deliveries and swift technical assistance.

The recycling of plastics is booming, not least because of the EU’s ambitious recycling targets – the circular economy package stipulates a recycling rate of 50 % until the year 2025. Last year, the growing demand for recycled material prompted PET to PET to approach Starlinger recycling technology with the request for an increase in capacity of the recycling line. The customer was convinced that in cooperation with Starlinger’s specialists, an even higher throughput could be achieved. Through a detailed analysis, they jointly identified areas that showed potential for an increase in performance. Based on this analysis, Starlinger recycling technology compiled a package that was integrated into the line in several stages. The upgrade involved numerous process steps such as drying, extrusion, filtration, and energy recovery. „After completion of the revamp, the line runs at 20 % more output with consistent quality and constant IV“, states Christian Lovranich, Head of Process Engineering of Starlinger recycling technology. „By doubling the capacity for energy recovery, we have not only made the line more productive, but also much more energy-efficient. The successful upgrade at PET to PET shows that even after many years of reliable operation, recycling lines can still achieve an increase in performance.”

In PET recycling, the availability of input material is a limiting factor. At present, PET to PET can only partially cover its material needs from Austrian collection systems because the collected PET bottles are also popular among manufacturers of other products as a secondary raw material. Examples of other products made from rPET are films for the food industry and strapping bands. In order to obtain enough raw material for new PET bottles, PET to PET also purchases bales from neighboring countries. At the recycling plant, transparent, blue, and green bottles are processed. The owners may exercise their preemptive right to the regranulate, the rest is sold to interested parties on the free market.

With 3 out of 4 recycled PET bottles, PET recycling is already a prime example of a functioning circular economy in Austria. In the next years, this rate shall be increased even more in order to reach similar top values as Germany (>90 %). “The direction is clear; the technologies are available,” states Christian Strasser. “It lies within the responsibility of the manufacturers to close the circuits and design their products with an eye on recyclability.” Currently, the usage of many different kinds of plastics as well as multi-layered food packaging complicates recycling activities. “For PET bottles, excellent structures for collection and recycling are already in place,” Strasser emphasizes. “Such structures must also be established for other kinds of plastic packaging so that the material streams can be returned to the production process. In addition, our society will need to undergo massive changes in terms of waste reduction and a more responsible use of our limited resources.”