Sutco® launches new model series of its WENDELIN composing system

Sutco RecyclingTechnik GmbH launches the latest model series of its proven WENDELIN composting system, setting new standards in the efficient and sustainable treatment of biological waste. In view of the increasing global demand for advanced waste management solutions, the WENDELIN now offers even more performance and flexibility.

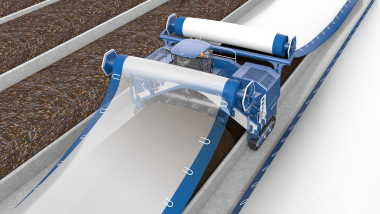

The name WENDELIN stands for a robust, powerful machine that effortlessly processes large quantities of biological waste. And rightly so, because the windrow turner delivers high-performance technology for large throughput volumes.

The composting process takes place in a single table windrow, which is made up of several windrow fields. This innovative concept ensures optimum utilisation of the composting area. Every week, the WENDELIN turns all the material in the composting hall and ensures ideal conditions for biodegradation through continuous movement and aeration, while an integrated irrigation system guarantees the optimum moisture level of the material at all times. The sectional ventilation floor under the entire composting area enables economical air flow thanks to an intelligent control system. At the same time, it drains and collects the resulting process water.

Sutco-WENDELIN stands for flexibility and efficiency

The WENDELIN model series offers an impressive range of throughput capacities from 40 000 to 100 000 t/a per machine, which can be multiplied by combining several treatment lines. Thanks to its compact design, which requires no logistics space for wheel loaders, for example, the WENDELIN offers outstanding space efficiency. Its flexibility is also reflected in its wide range of applications: in addition to typical biowaste and green waste, the system processes fermentation residues and organic waste from household waste.

Maximum efficiency and environmental friendliness in operation

Thanks to the high degree of automation, the Sutco-WENDELIN guarantees consistently efficient operation – from feeding in the material to distribution and fully automatic discharge of the finished compost. An innovative system control monitors the entire process and enables 24/7 operation with minimised personnel deployment.

With high throughput rates, the WENDELIN is unbeatable in terms of costs and energy efficiency. By reusing process water, plant operation can be virtually wastewater-free, depending on the application, which significantly reduces the costs for leachate treatment. Efficient exhaust air purification ensures compliance with all legal regulations and emphasises the environmental friendliness of the system.

Proven quality and customer-orientation have been incorporated into its further development. The focus is on user-friendly operation and maintenance as well as the use of high-quality materials for maximum corrosion protection.

WENDELIN successfully in operation

The Zweckverband Abfallwirtschaft Region Hannover (aha) has already successfully installed the second Sutco WENDELIN. In addition to replacing the transfer machine, the fully automatic feed system from Sutco was also integrated, which significantly increased the efficiency of the system. Sutco RecyclingTechnik replaced the first windrow turner for aha Hannover in 2016.

Another success: Stadtreinigung Hamburg has also commissioned WENDELIN technology to expand its site capacity. The new treatment line complements the existing system for the finished composting of fermentation residues. Start of construction will be in summer 2025.