Textile recycling system to the Swedish company Renewcell

International technology Group ANDRITZ has received an order from Renewcell to supply textile recycling equipment to its greenfield recycling plant in Sundsvall, Sweden. Start-up of the plant is scheduled for the first half of 2022.

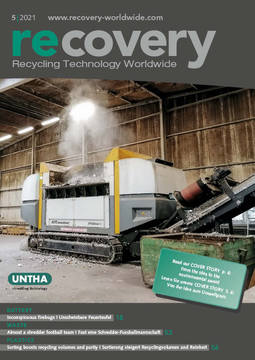

Core elements of the new recycling system will be ANDRITZ ADuro shredders, which will shred used textiles in only one shredding step. With unique capabilities, the ADuro shredders cut the incoming material uniformly and cleanly while enabling a very high throughput. In the subsequent separation stages, contaminants like buttons and zippers will be removed from the shredded textiles. Renewcell uses this pre-treated material to produce a pure, natural dissolving pulp made from 100 % recycled textiles.

In addition, the scope of supply includes additional key pieces of equipment. With the state-of-the-art equipment from ANDRITZ, up to 60 000 t of used textiles per year can be handled in the new recycling plant.

Since 2016 Renewcell has cooperated with ANDRITZ to develop its process in its test plant in Kristinehamn/Sweden, convincing the company of the high performance and quality of ANDRITZ technology in processing challenging materials such as textiles.

Renewcell, headquartered in Stockholm/Sweden, was founded in 2012 and is specialized in the recycling of textiles. The recycling technology employed by Renewcell dissolves used cotton and other cellulose fibers and transforms them into a new raw material, the so called Circulose® pulp, which is further used to make biodegradable virgin quality viscose or lyocell textile fibers for the fashion industry.