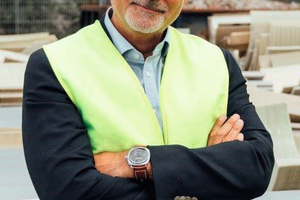

The success story of a young enterprise

In the beginning, there was an idea and a man who grasped an opportunity, with his experience and his employees, and closed a recycling gap. He even received Berlin‘s Green Tech Award for the solution that was developed. But let‘s first go back to the beginning.

The challenge could be found in locating a process for the re-use of life-expired rotor blades. The founding of neowa took place simultaneously with talks held with the Nehlsen group in Bremen; the neocomp associate, in which neowa implemented operations for the preparation of fibre-composite wastes, which consist very largely of wind-power system rotor blades, was thus started in 2015.

The founding of neocomp was followed with the commencement in late 2015 of continuous operation, i.e. regular input of waste and regular output of secondary resources. But how are these glass-fibre-containing materials recycled, and who purchases the resultant products?

„Without the incredible commercial and technical knowledge of my colleagues, both men and women, such as, for example, plant manager Stefan Gross, this would not have worked“, emphasises Kroll. „At that time, I was more concerned with strategic and business management matters.“

Glass-fibre composites can be used as a substitute for raw sand; this is therefore a materials-route valorisation, and one that conserves resources. The cement industry has been suffering for years from increasingly scarce raw sand, and is seeking clever alternatives. This was the basic concept and the motivation for the founding of neowa. The company has supplied around 30 000 t of raw sand substitute to the cement industry since early 2016. These 30 000 t are made up of equal amounts of pulper rags of suitable quality from the paper industry and recycled and prepared glass-fibre composite materials. This product is an extremely light, fluffy material with a large surface area, which optimises burnout. It is then fed to the calciner in the cement plant.

And what is the picture concerning the availability of the necessary waste materials? „There have been phases where we would have liked more GRP (glass-fibre-reinforced plastic) in individual weeks, but times of shortage are becoming less and less frequent“, Kroll notes.

„Over time, we have learned that we cannot accept certain types of production waste, despite the fact that it is GRP, since it blocks production. These quantities of material are, of course, then lacking for us in our planning. Uniform supply of rotor-blade scrap from decommissioning only started this year, however. In previous years, we received rotor-blade scrap from bad batches, and from development projects, etc., but returns from demolition have now started and are becoming ever more important, due to the coming into effect of the new Energy Feed-In Act.“

In 2017/2018, there was, for example, a large offshore rationalisation, and seventy-two blades – at nearly 25 t GRP per blade – arrived in Bremerhaven and were processed by neowa on the spot in the duty-free harbour there. This was one of the new company‘s first very large projects.

Another highlight was the presentation of the Green Tech Award in Berlin in 2017 as a reward for the recycling solution for rotor blades from wind-power turbines using a so-called zero-waste process. A total of four companies were nominated in this category - Epson, Remondis, Veolia … and neocomp. One of the essential points here is the fact that GRP cannot be processed alone, it‘s a hazardous process, due to the generation of dust, in particular. „Mixing with the right flows of paper is, ultimately, the process-engineering capability that we have built up here“, explains Kroll.

One problem in GRP recycling remained, however – the highly fluctuating supply of material. So then it was time for the next strategic decision – a second specialisation was to be set up. And this success story, too, is also the result of active marketing and careful process-engineering enquiries. Jointly with Nehlsen AG, neowa planned, and completed in 2018, the construction and operation of a waste-preparation plant for Tetra Paks. There was a search for a suitable comminution system which could cut this material – Tetra Paks compressed into bales – energy-efficiently. „Previously, we had already gained initial experience with UNTHA shredders at our customers‘ plants“, reports Stefan Gross, plant manager at neocomp. It was a happy coincidence that a UNTHA roadshow visited Berlin and allowed neocomp to test its material. It worked. „We knew that this was the right machine“, Gross affirms. Tetra Paks are a homogenous material constantly available in large quantities. Further tests demonstrated that the UNTHA XR3000C mobil-e shredder reliably produced an extremely good end product with only little material wear. And this was the starting point for a new preparation line. There was, here again, however, the question of who would purchase the prepared recyclable. And, once again, the answer was found at a cement plant. A Danish cement plant had a scarcity not of raw sand, but of aluminium-containing feed materials. This then closed the recycling circuit and enabled production to start. „neowa wanted to start production in early 2018, but we had much longer delivery times, and the question also arose of which of the UNTHA machines would meet our needs most precisely. We then found a way of providing a suitable machine – on a hire-purchase basis, since the customer‘s business had also only just started. After expiry of that agreement, there was the no problem about the machine being taken over by neowa.“, reports Daniel Wresnik, from the Marketing and Sales department of UNTHA shredding technology GmbH, Austria. The key to success was the symbiosis of the operator‘s business model, machine availability and the machine configuration. This machine is a semi-mobile package, i.e. the shredder machine is mounted on a tracked chassis, which is operated and can be relocated by means of a gasoline-fuelled power generator. On the other hand, the shredder itself is operated entirely electrically from an external energy supply. The drive concept for shredder operation is based in all cases on an electro-mechanical principle – this requires an external power supply, but the benefit here, in addition to energy-efficiency and high throughputs, is an extremely compact and flexible machine, particularly in view of the location involved.

After successful operation of this processing line, neowa also ascertained that the material was constantly available in even larger quantities. As a result, we began looking for an additional UNTHA shredder. And there, again, as luck would have it, the cement plant wanted the supply of a second grade of this material with a higher calorific value. Here, the waste from the yellow bag was also co-processed – a new material was added, and also had to be tested. At the same time, UNTHA had launched a new cutting system and unveiled it at the IFAT 2018: the XC-cutting-system. And precisely this was particularly good not only for shredding of Tetra Paks but also of the high-energy materials from the „yellow bag“. Throughput was doubled using the new XR3000XC mobil-e shredder, to 40 000 t. In addition to expanding the preparation line in Bremen in 2019, a second line for preparation of Tetra Paks started operation at neowa‘s Brake location in 2021. „This further development from UNTHA shredding technology in 2018 permits an extremely modu lar configuration of the machine, depending on needs and material, together with a new cutting system that is significantly more effective and more durable. This principle does, however, react sensitively to larger disruptants, but this has not resulted at neocomp/neowa in any major difficulties. This positive experience with neowa convinced us yet again that this development was exactly the right step for UNTHA“, summarises Daniel Wresnik on his experience from this project. And Stefan Gross himself is more than satisfied: „Even the first UNTHA shredder that we used fulfilled our expectations ideally. Investment in another two UNTHA machines enabled us to consistently pursue our already successful preparation line.“

Author/Autorin:

Dr. Petra Strunk, Editor in chief/Chefredakteurin recovery