THM recycling solutions GmbH supplies small granulator type ZM300 for university research center

The University TU Bergakademie Freiberg operates a technology center for the coordination project FOREL (research and technology center for resource-efficient lightweight structures in electromobility). There, both own research work and development projects in cooperation with the industry are carried out.

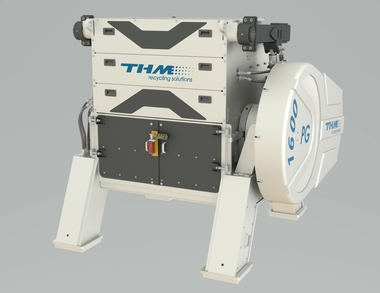

For this purpose, a small, yet robust and powerful shredder was needed. A granulator type ZM 300 series from THM recycling solutions GmbH fulfills these requirements on a small scale. The granulator is one of the radial gap rotor shears with a sheared load on the feed material. The flat knives attached to the rotor have catting angles of 90 ° and are designed for the use of all four sides. The shear edges move past each other and lead to shredding of the material by exceeding the deformation capacity in the shear surface. Therefore, these machines are mainly used for soft to medium-hard materials with non-brittle material behavior.

With a loading speed of more than 10 m/s, the granulator is no longer one of the slow-running rotor shears and therefore achieves a comparatively higher specific throughput due to the higher speed. The rotor knives are adapted to the contour of the stator knife and allow a very precise setting of the radial gap width of a few tenths of a millimeter along the entire shear edge. Together with the robust construction, plastic or elastic materials such as plastic films or relatively solid pieces of metal made of aluminum can be shredded efficiently.

At the Institute of Mineral Processing Machines, the machine is used to shred lightweight structures from various sources such as vehicle construction or the wind energy sector. The area of application extends to the shredding of battery structures and fiber-reinforced plastics to metal components. Through the constructive execution of the tool design in connection with selected sieve hole size, very narrow and defined particle size distributions can be created, in which a rather cubic particle shape is created. Especially with RDF or fiber-reinforced plastics with requirements for the upper limits of the particle dimensions to be observed or aspect ratios, these are convincing arguments for the selection of the shredding machine.