TOMRA further strengthens its position in AI

Leading collection and sorting solutions provider TOMRA further strengthens its position in the field of artificial intelligence by acquiring a 25 % stake in PolyPerception, a pioneering start-up offering AI-based waste flow monitoring. TOMRA began a collaboration with PolyPerception in December 2022, and this investment in the company is another step in TOMRA‘s journey to transform resource recovery with the latest technology.

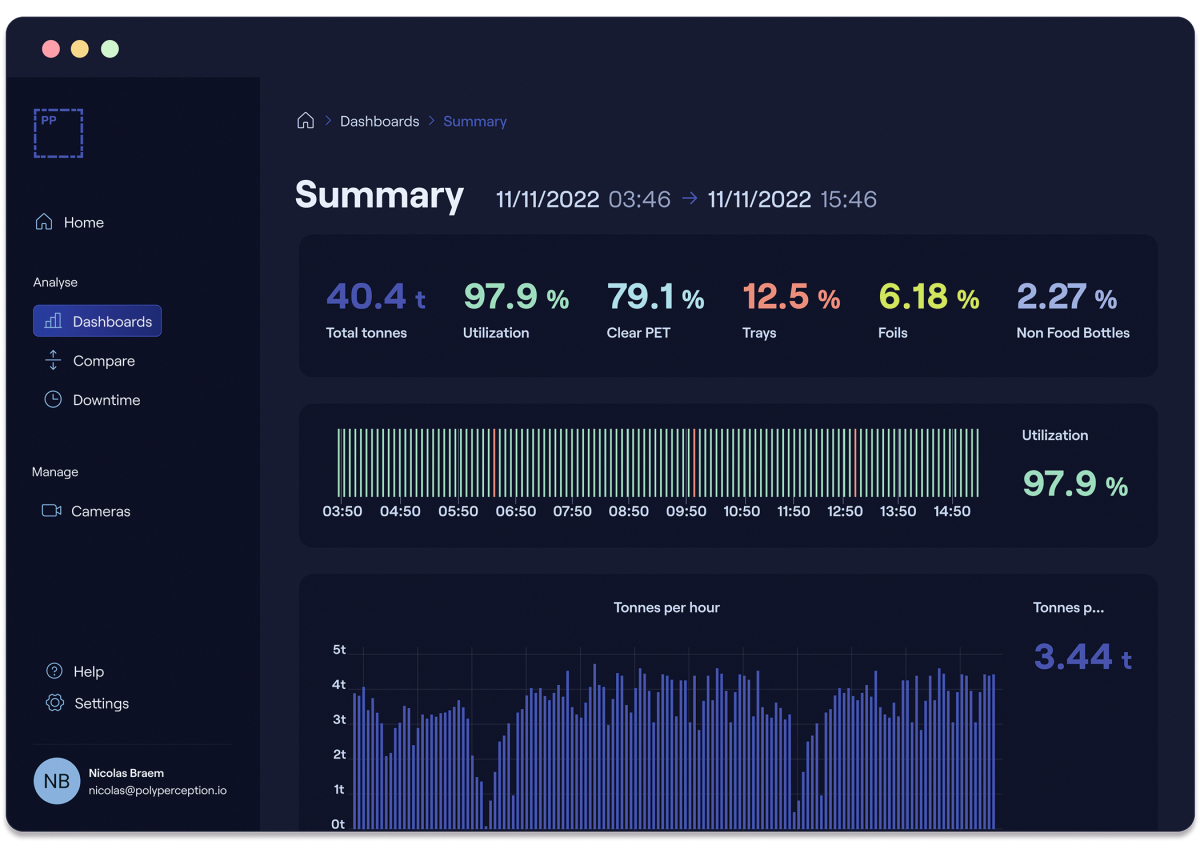

Visualisation of the data

Visualisation of the data

© TOMRA

Dr. Volker Rehrmann, Head of TOMRA Recycling, said: “By expanding our cooperation with PolyPerception, we can combine our advanced material sorting systems and cloud-based monitoring solution with the company‘s innovative material analysis. This synergy enables us to enhance the optimization of the entire process and material flow, providing a significant advantage to our customers. Plus, it now allows us to harness PolyPerceptions‘ data and AI expertise for continued enhancements to our machinery.”

Waste analysis for PET recyclers and sorting plants

PolyPerception offers a waste analysis solution for PET recyclers and sorting plants. By measuring data at key points in the sorting process, the company helps sorting facility operators to continuously assess the quality of sorted streams and the loss of good material in the residual stream, to enable data-driven decisions. It further functions as an automated compliance system, ensuring adherence to stringent regulations governing food-grade recycling and local legislation. With the regulatory landscape evolving towards greater stringency, PolyPerception anticipates growing demand in the market for its transformative technology.

AI and data at the heart of TOMRA

For TOMRA, AI and data have long been an integral part of the company‘s R&D activities and product portfolio with specific applications within machine learning, recognition, and infrastructure. In 2019, the company introduced the industry‘s first deep learning technology for waste sorting. This innovation combines deep learning technology with TOMRA‘s traditional sensors, enabling the sorting of difficult-to-classify materials, such as the removal of PE silicone cartridges from polyethylene (PE) streams.

Since then, TOMRA has continued to invest in the development of deep learning, which is considered a subset of AI and machine learning. An application for wood chip classification followed in 2022. Rehrmann confirms: “We are convinced that AI together with the power of our well-established sensors will heavily boost material circularity. Our internal development teams are working at high speed.”