Two-Shaft Ripper carefully shreds valuable e-waste and cooling devices

E-waste is one of the fastest growing waste streams. By 2030, a global output of around 75 million t is being estimated [1]. However, this is not just waste: old devices contain vast quantities of valuable raw materials such as copper, aluminum and rare earths, but also toxic and environmentally hazardous substances such as lead, mercury. Refrigerators also contain greenhouse gases such as chlorofluorocarbons (CFCs). Thorough recycling of e-waste is therefore important, but also poses a number of challenges, requiring special recycling processes.

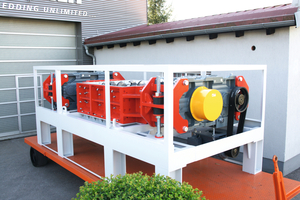

The first step is therefore pre-shredding, which reduces the size of the components and makes it easier to separate the individual materials. For this purpose, ERDWICH Zerkleinerungs-Systeme GmbH develops recycling lines specifically for e-waste, including seamlessly integrated shredding systems. One of these, the fully automated RM1350 two-shaft ripper, was on display at this year’s IFAT in Munich.

With around 30 million t of e-waste generated in 2022, Asia is the world’s largest producer of this valuable resource [2]. In a per capita comparison, however, Europe takes the lead: in Germany, each person produces an average of 18 kg per year [3]. This includes all electrical appliances: from battery-powered children’s toys to telephones, smartphones as well as computers, monitors and televisions to large household appliances such as washing machines and dryers. These everyday machines contain valuable raw materials such as copper, silver, gold, lithium, cobalt and rare earths, which are very complex and expensive to mine. Moreover, these are finite resources and their natural deposits are constantly dwindling.

The valuable resources from old appliances must therefore be returned into the production cycle. The EU has set a recycling target of 65 % of all electrical devices put into circulation – although Germany is still 20 percentage points away from this target. “Part of the reason for this is that the processing of so-called e-waste is quite challenging,” says ERDWICH Managing Director Harald Erdwich. “The appliances consist of many different materials and components, which first have to be laboriously dismantled and separated. In addition, older refrigerators, for example, also contain harmful substances such as CFCs, which under no circumstances may be allowed to escape into the atmosphere.”

Gentle and energy-efficient e-waste recycling

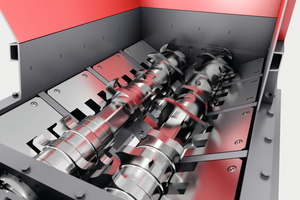

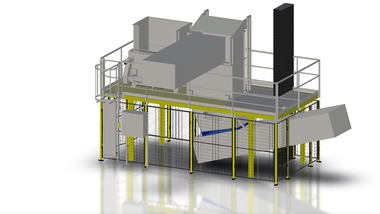

After initial sorting, the e-waste collected for recycling is first pre-shredded. The process turns the individual parts into a slightly more homogeneous mass, which facilitates further separation of the individual components and materials. For this purpose, ERDWICH has developed the RM1350 shredder for coarse materials, which can be retrofitted into existing recycling lines. The length of the cutting unit of the two-shaft ripper can be configured between 1500, 2000 and 2500 mm to precisely match the input consisting of electrical devices, as can the electromechanical drive power of 45 to 132 kW, including a frequency converter for individually setting the shaft speeds. Depending on the size and material composition of the processed electrical devices, a throughput of up to 5 t/h is possible.

„The individually inserted knives made of wear-resistant special steel allow for different narrow and wide cutting sequences and blade arrangements,” explains Erdwich. “In this way, I can ensure an optimum shredding result as the basis for subsequent material separation and recovery processes.” The smaller and more homogeneous the remaining parts are, the faster and with less energy plastics and other organic components can be separated from valuable metals. However, to prevent breakdowns and system downtimes when handling particularly bulky large electrical devices, the fully automatic two-shaft ripper is equipped with a specially developed PLC including automatic reversing and shutdown.