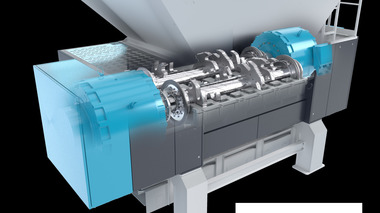

Vecoplan: From solid lumps to granulate

Vecoplan AG will demonstrate its high level of expertise in shredding technology on a floor area of 270 m². In doing so, the leading manufacturer can call upon nearly 50 years of experience and a wide range of products. All machines are equipped with energy-efficient drive concepts and were developed with the solution in mind. The V-ECO range, which is one of the best plastic shredders on the market, is only one example.

These machines are easy to maintain, repair and operate. The hydraulic sing-out bottom flap and the swing-out screen enable the operator to gain easy access to the rotor. He is able to immediately remove tramp material, easily rotate or change counter-knives, and reconfigure the machine – for example change the screen perforation size when changing product. The material is fed continuously thanks to the angled design of the machine base and the adjustable ram. These two features ensure that the process runs trouble-free and continuously. One IBC can be shred in only 30 seconds. The customer saves time, considerably reduces the reject storage area and additionally optimises his economic effectiveness with regard to the costs and quantities of raw materials used. The system can process up to 5000 kg of material per hour.

The well-known and proven VAZ series has been provided with new rotor concepts and optimised power units. The robust all-rounders can be fed directly without a dosing device.

Plastic and wood are prepared for their second life by Vecoplan machines. Data storage media, such as hard disks on the other hand, have to be destroyed. Depending on the sensitivity of the data stored on the hard disks, they have to be shredded in accordance with the required security level. Vecoplan also offers detailed information on the VDS 800 shredder for this purpose. These high-torque machines enable rapid start-up and stable operation. In the meantime, they have become established as leaders in this field.

The shredding specialist’s portfolio also includes powerful machines for processing alternative fuels. In this regard, Vecoplan will be presenting a complete new machine at IFAT. The pre

shredder is best suitable for the processing of in-dustrial and production waste as well as bulky waste into high quality RDF. Visitors of IFAT will be able to examine the new machine live in detail at the Vecoplan booth.

But Vecoplan offers more than just powerful shredders. The experts also supply components for the storing, metering and conveying of different materials. Vecoplan configures these according to the application and its requirements.

//www.vecoplan.com" target="_blank" >www.vecoplan.com:www.vecoplan.com

Hall B5, Stand 229 und 328