Aurubis invests in innovative system at the Lünen site for fully automated sample preparation

02.07.2024Aurubis has successfully commissioned a new system that is setting new standards in the recycling industry at its Lünen plant. Sample preparation of feed materials, such as e-scrap, is now fully automated with the help of cutting-edge robotics. This innovative system now efficiently delivers reliable samples to the laboratory in just an hour for a sample preparation process that used to be carried out manually in up to 12 stages and could take five days. Aurubis invested a mid-single-digit-million-euro amount in the new system. The initial system concept was developed around three years ago as part of the Group-wide automation and digitalization strategy.

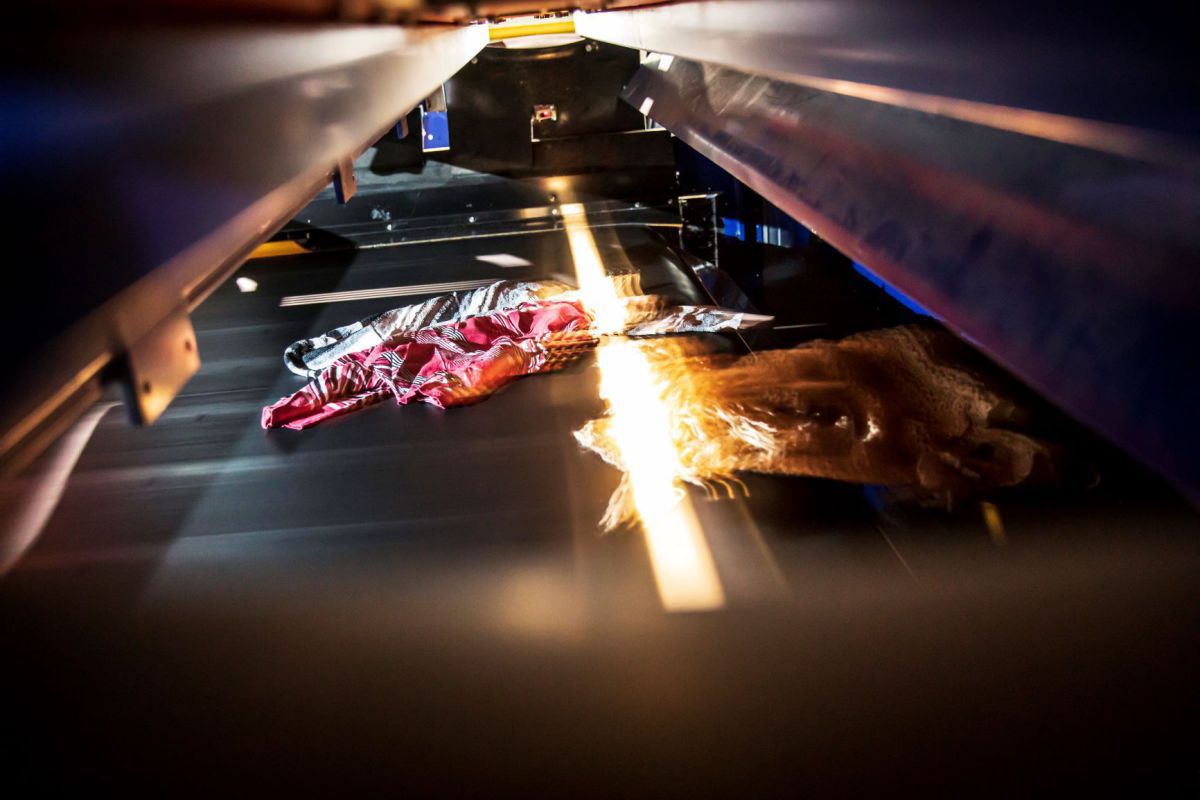

In the sample preparation process, which was previously carried out manually in up to twelve steps and took up to five days, the innovative system now delivers reliable samples for the laboratories efficiently and safely in just one hour

In the sample preparation process, which was previously carried out manually in up to twelve steps and took up to five days, the innovative system now delivers reliable samples for the laboratories efficiently and safely in just one hour

© Aurubis AG

“The new system is absolutely state-of-the-art and, with up to 10 000 samples per year, the most powerful of its kind in our industry. It’s a flagship project: for both the Lünen site and the entire Aurubis Group,” Lünen Plant Manager Verena von Weiss said. “With a dedicated team, we moved ahead with the planning, construction and commissioning in less than a year. We gathered crucial experience to make the process even more secure, which all Aurubis sites will now profit from.”

Innovation with potential: the Lünen site and e-scrap are just the beginning, additional sites and input materials to follow soon

The system now online is the first of its kind in the Aurubis Group, and a model for other sites and materials. The company in investing in a system for the Hamburg site as well, and initial tests with materials specific to Hamburg have already been successfully conducted in Lünen. The Aurubis plants in Bulgaria (Pirdop), Belgium (Beerse), and the US (Augusta) are slated to follow. And e-scrap is only the beginning, as the system offer even more potential: Other valuable materials such as intermediates that accumulate in the smelter network can also be efficiently and securely sampled in the future. The system already enables the continuous mechanical sample preparation of materials like PCBs, shredded materials containing iron, and dried slimes.

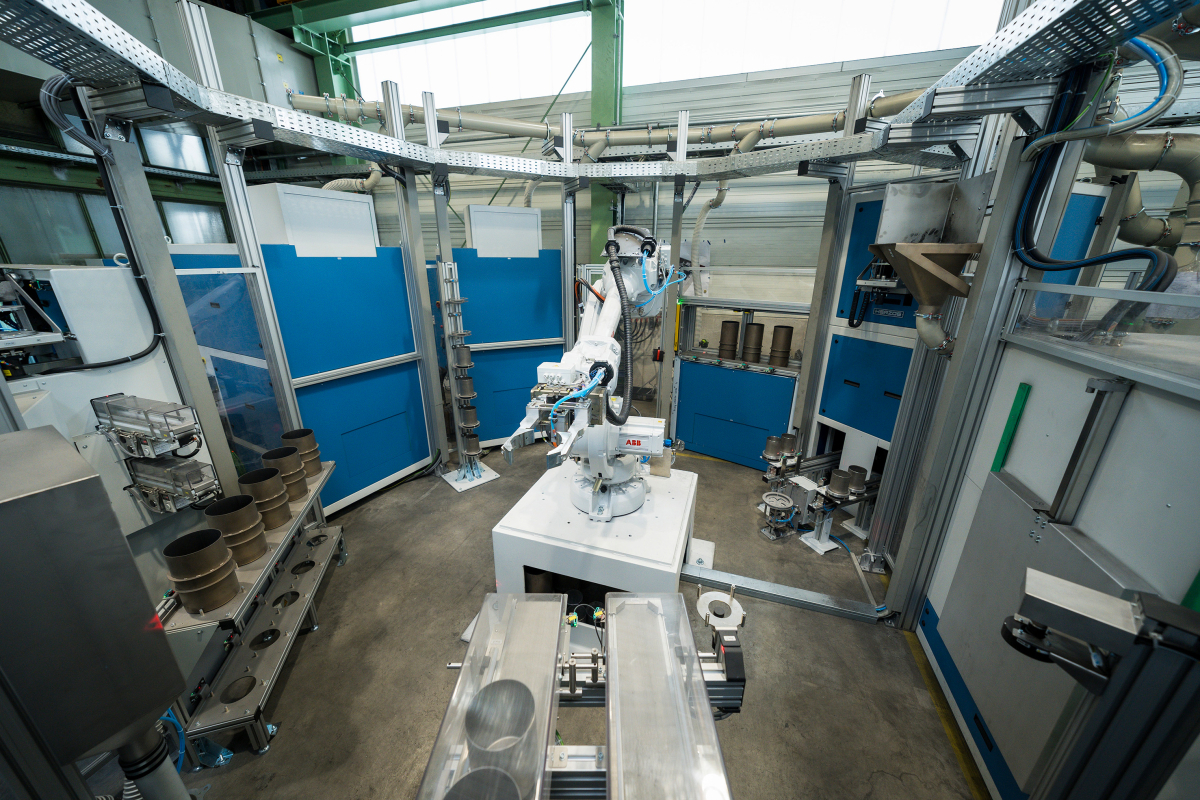

Aurubis Lünen: From now on, the sample preparation of incoming materials such as electronic scrap will run fully automatically and with the help of state-of-the-art robotics

Aurubis Lünen: From now on, the sample preparation of incoming materials such as electronic scrap will run fully automatically and with the help of state-of-the-art robotics

© Aurubis AG

Triple the security: new system boosts occupational safety, environmental protection, and process security

In addition to the time factor, security also plays a central role in automating work processes. The new sampling process is an advancement in three ways:

For one, it positively impacts employees’ occupational health and safety since it eliminates manual work stages and significantly reduces noise emissions. Second, locally suctioning and filtering particulate matter in the completely enclosed system reduces the already small environmental impacts to a minimum. Third, the new system protects sampling even better from possible outside interference: The self-contained process leaves practically no room for manipulation. Every assessment is fully documented, including a photo record, and can be verified via analysis software on an ongoing basis. The automation therefore significantly enhances the quality and reliability of the entire process.

Aurubis invests in transparency and trust in the competition for recycling material

“Our suppliers’ trust is our most important currency in the global competition for recycling material,” COO Multimetal Recycling Inge Hofkens said. “We process about 1.1 million t of recycling material in the Group each year. With the fully automated system that is now in operation, we are making a targeted investment in strengthening transparency and trust in Aurubis,” Hofkens continued.

Reliability, trust, speed and sample quality are key when it comes to sampling and determining the value of a delivery. The wide variety of material combinations in today’s end products mean recycling material is growing increasingly complex, which raises demands on modern sampling. Here too, the automated process is now facilitating even more transparency, more reliability, and fully documented sampling results. And even more trust between business partners.