Denmark's leading recycling company relies on XPower® wheel loader from Liebherr

21.03.2023RGS Nordic specialises in recycling construction and demolition waste materials and is the market leader in Denmark. It operates a fleet of around 130 construction machines, about two-thirds of which have been supplied by the Liebherr Group. Among them are 40 XPower® wheel loaders of various sizes featuring wheel power-split travel drive as standard and returning notably low fuel consumption.

40 Liebherr XPower® wheel loaders are in use at RGS Nordic for material handling

40 Liebherr XPower® wheel loaders are in use at RGS Nordic for material handling

© Liebherr

Every day, more than 1000 truckloads of construction waste and other material arrive at RGS Nordic's facilities to be converted into reusable and circular products and reintegrated into the product cycle. The 40 Liebherr XPower® wheel loaders are used for material handling as part of the process.

CO2-saving and more fuel efficient: The Liebherr XPower® wheel loaders impress with their power-split travel drive

CO2-saving and more fuel efficient: The Liebherr XPower® wheel loaders impress with their power-split travel drive

© Liebherr

Michael Jørgensen, strategic purchasing manager, commented: "The Liebherr wheel loaders need less fuel, are powerful and have hardly any downtime. We are particularly impressed that we achieve 30 % more productivity with the same fuel consumption than with comparable wheel loaders in this size class." Those enormous advantages in fuel consumption also ensure lower CO2 emissions, meaning the machines align perfectly with RGS Nordic's core values.

The L 576 XPower® wheel loader is in use at Denmark's leading recycling company RGS Nordic

The L 576 XPower® wheel loader is in use at Denmark's leading recycling company RGS Nordic

© Liebherr

Clear statement: Recycling is the future

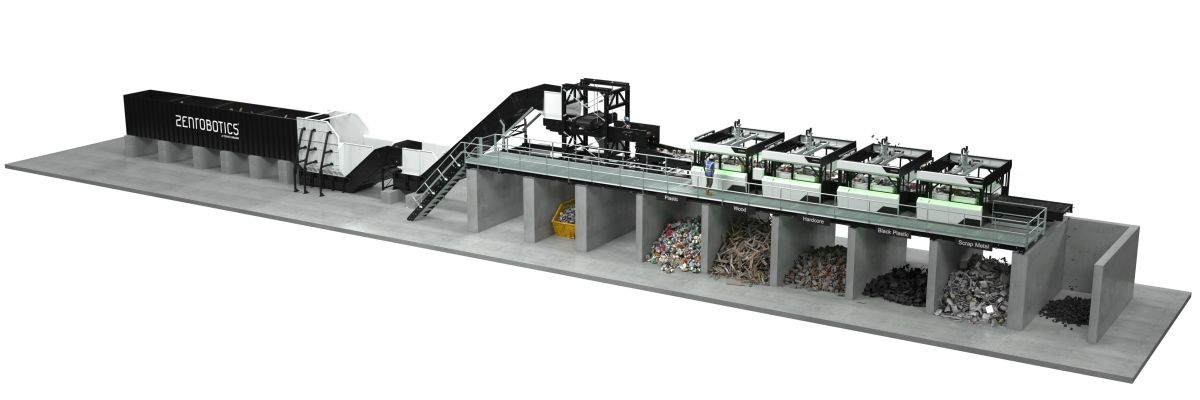

At Denmark's largest waste management site, recycling the delivered material is top priority. "We aim to make circular economy a sustainable business", added Jørgensen. The Liebherr wheel loaders play a key role in helping the company achieve that aim. On one hand, they transport the bulky waste pre-sorted by Liebherr excavators to the sorting plants, and on the other, feed the numerous crushing and screening plants with various construction wastes. At the end of the treatment process, the recycled material is reused on construction sites around Copenhagen.

Sights set on the future: Hubert Feneberger (Liebherr-Werk Bischofshofen), Michael Jørgensen (Strategic Purchasing Manager – RGS Nordic) and Birger Hjelm (Sales Manager – Liebherr Sales Partner)

Sights set on the future: Hubert Feneberger (Liebherr-Werk Bischofshofen), Michael Jørgensen (Strategic Purchasing Manager – RGS Nordic) and Birger Hjelm (Sales Manager – Liebherr Sales Partner)

© Liebherr

RGS Nordic also returns the supplied, partly contaminated material to the product cycle through specialised processing operations, for example by adding substances such as calcium and by constantly shifting the piles of earth using the Liebherr wheel loaders. That function is important to ensure a reliable oxygen supply during composting. Once that operation is complete, the XPower® machines load the recycled material on to trucks for RGS Nordic's customers to use as a natural raw material on a wide variety of construction sites rather than rely on new products.