European recycled phosphorus can be exported to Canada

23.11.2023In a new collaboration, the innovation company EasyMining and the German utilities company Gelsenwasser will start developing a market for a premium feed product together with Friesen Group, a second-generation family-owned Canadian feed company.

From left: Jan Svärd, CEO at EasyMining, Marvin Friesen, CEO at Friesen Group, Sara Stiernström, Product Manager at EasyMining, Pär Larshans, Director of Sustainability at Ragn-Sells Group

From left: Jan Svärd, CEO at EasyMining, Marvin Friesen, CEO at Friesen Group, Sara Stiernström, Product Manager at EasyMining, Pär Larshans, Director of Sustainability at Ragn-Sells Group

© EasyMining

EasyMining aims to recycle high-quality phosphate from incinerated biosolids within their joint venture, Phosphorgewinnung Schkopau, together with Gelsenwasser. The phosphate is suitable as a feed raw material, being safe and highly digestible in animals. “If we are serious about creating a sustainable society, we need to use the resources we already have, over and over again. Therefore, signing this Letter of Intent with Friesen Group, with the purpose of developing a world market for recycled phosphorus, is a major step,” says Jan Svärd, CEO of EasyMining.

For the first time globally, recycled phosphate from biosolid ash will be developed into premium feed products aimed for the North American market. “I am very happy that we at Friesen have the possibility, together with EasyMining, to first develop and then supply the market with recycled phosphorus. The better environmental footprint will be a winning concept,” says Marvin Friesen, CEO of Friesen Group.

The planned facilities will utilise the Ash2Phos technology to extract more than 90 % of the phosphorus from the ashes of incinerated biosolids. Developed and patented by EasyMining, this process also removes nearly all contaminants, enabling a circular flow of phosphorus. The first plant is expected to be up and running within 3 to 4 years.

The final product will be cleaner than any mined phosphorus on the market today. However, EU legislation prohibits its use in several applications, like organic farming or as feed phosphate since the original biosolids are classified as waste.

“We are pleased that Canada’s progressive policies allow for the use of recycled phosphorus as a feed ingredient. We do know that it will take time to have all regulatory approvals in order, and therefore we have already started now,” says Dr. Sara Stiernström, Product Manager at EasyMining who will lead the work going forward.

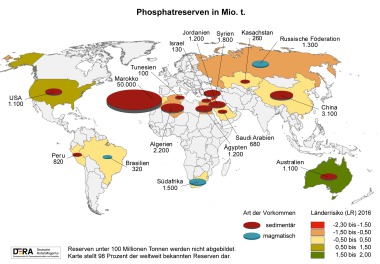

The world’s population is expected to increase by two billion people in just 30 years, with a much larger share living in cities, according to the UN. Having enough to eat without increasing the strain on the planet’s limits requires new and innovative attitudes to food production. “Without phosphorus there will be no life, but today we are dependent on imports from traditional sources. At the same time, we have plenty of phosphorus right here in our wastewater - we just have to start using it and that’s what we are going to do, together with Friesen,” says Jan Svärd.