First Metso high-performance EtaRip metal recycling pre-shedder unit to be installed in North America

12.06.2018Metso has received an order to supply its first Metso LindemannTM EtaRipTM pre-shredder in North America. The customer, Milliron Iron & Metal, chose Metso's solution due to the robust design and performance of the machine, combined with Metso's service and support capabilities in North America. The solution fulfills restrictive environmental and commercial regulations and it has already proven its performance in many countries globally. "We are excited to have secured our first EtaRip order in North America. The unit will be installed in the fall of 2018. Once the unit has been commissioned, we are confident that our customer will be pleased for their decision. We also look forward to being able to demonstrate the benefits of this product to a new audience," says Keith Carroll, Vice President, Metal Recycling Americas.

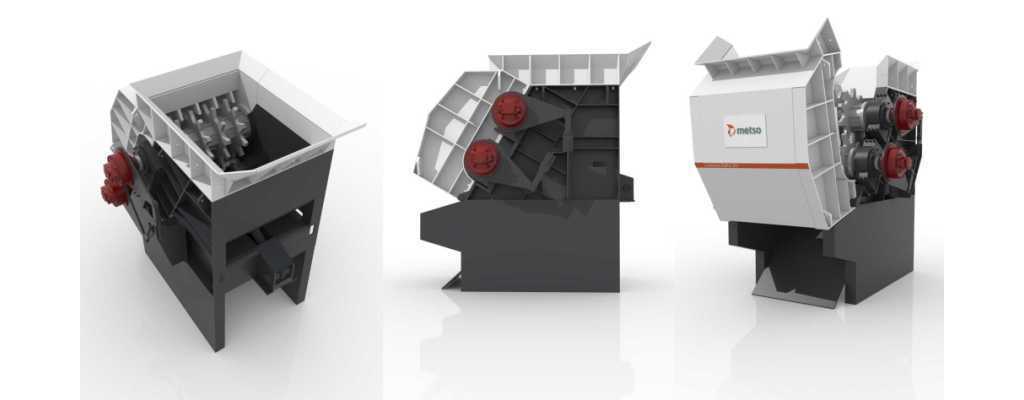

Lindemann EtaRipTM offers improvements in efficiency by pre-shredding bales and EVLs. Maximum production output and better sorting

Lindemann EtaRipTM offers improvements in efficiency by pre-shredding bales and EVLs. Maximum production output and better sorting

Source: Metso

EtaRip enables optimal operational efficiency

The EtaRip pre-shredder is a low speed, high torque recycling machine, which tears apart bundles or end of life vehicles (ELVs) before feeding these to the shredder plant. This results in a more homogeneous, easily processed feed to the shredder, which in turn enables the shredder to operate at optimal efficiency.

The advanced design of the EtaRip contributes to improved shredder castings' wear life and reduces peak electrical loads of the main shredder drive. It also provides protection against unshreddable materials that may be hidden inside bales or bulky materials. Furthermore, it greatly reduces the risk of unexpected explosions inside the shredding chamber, which could otherwise cause significant environmental or equipment problems.

Decades of experience in metal recycling

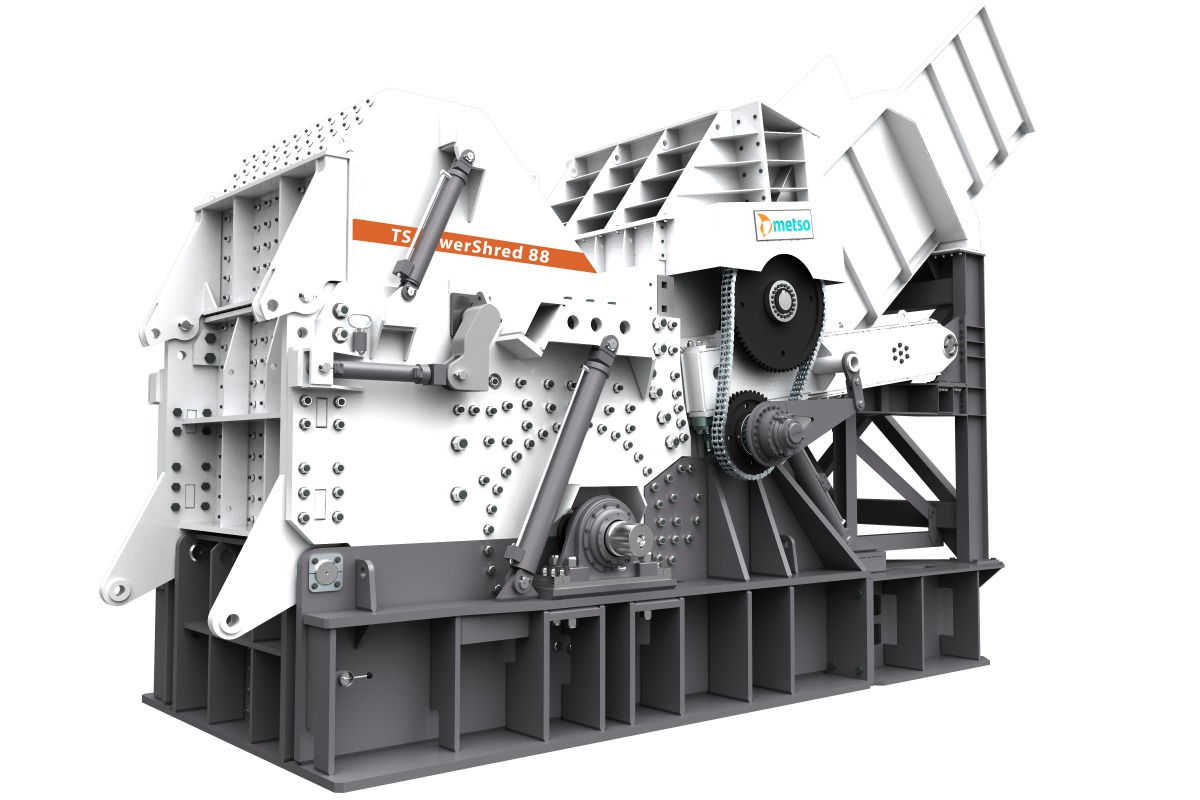

Metso's product offering for metal recycling covers a wide range of efficient solutions for the fragmentation, compaction and separation of virtually every type of metal scrap. Through the LindemannTM, Texas ShredderTM and N-SeriesTM product lines, Metso offers a full range of pre-shredders, shredders, shears, balers, and briquetters, along with the capability to develop custom solutions for customers' ferrous and non-ferrous scrap separation processing needs.