Focus on the circular economy

17.01.2024Continental has been setting standards for greater sustainability with its retreading of truck tires since 1903. The premium tire manufacturer has been using retreading to extend the service life of tires for more than 120 years – conserving resources and reducing costs. Continental retreads more than one million truck and bus tires worldwide every year. According to a study by the Fraunhofer Institute for Environmental, Safety and Energy Technology (UMSICHT), retreaded tires reduce CO2 emissions by up to 50 % compared to new tires. The amount of recycled and renewable materials in retreaded tires can be up to 85 %. In terms of traction, grip and safety, retreaded tires from Continental are every bit a match for new tires.

Jorge Almeida, Head of Sustainability at Continental Tires

Jorge Almeida, Head of Sustainability at Continental Tires

© Continental

"We have been a pioneer in retreading truck and bus tires for more than 120 years," explains Jorge Almeida, Head of Sustainability at Continental Tires. "Our tire retreading saves raw materials and costs – a real win-win situation for fleet operators and the environment."

Turning old into new: hot and cold retreading

Among other things, tires consist of a casing and tread. However, the casing may still be completely intact, while the tread has reached the end of its service life. Approximately 70 % of truck and bus tires were considered retreadable in 2022, based on industry reports and studies of tire manufacturing practices.

As part of the retreading process, the remaining tread rubber and, in the case of hot retreading, the sidewall of the tire are buffed and restored. This prepares the casing for a second and third tire life.

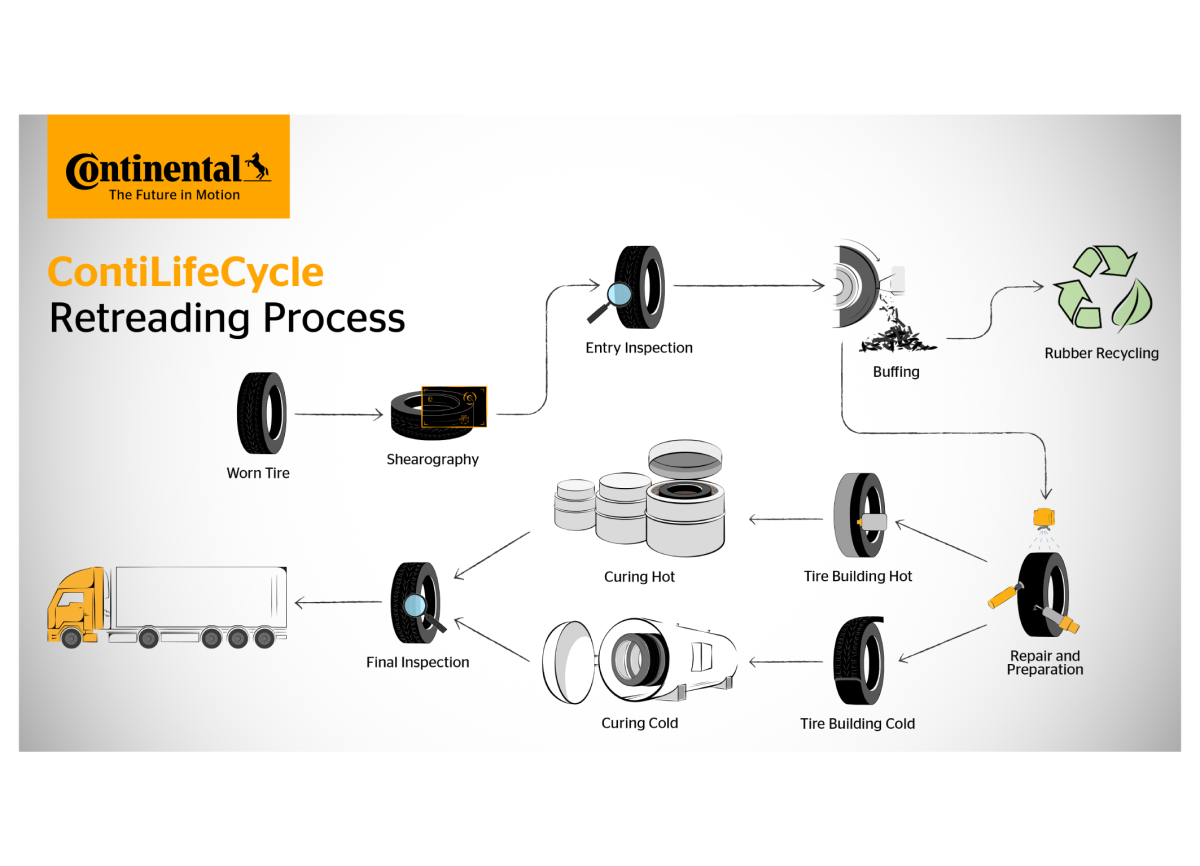

Retreading process for truck and bus tires

Retreading process for truck and bus tires

© Continental

Continental uses state-of-the-art analysis processes, production methods and recycling technologies in its hot and cold retreading. In hot retreading, the casing is restored from bead to bead in a hot vulcanization process. A new rubber compound is applied to the used casing. At Continental, this process is called ContiRe. In cold retreading, known as ContiTread in Continental's product range, a profiled and pre-vulcanized tread material is applied to the buffed casing. Cold retreading is carried out at lower temperatures and with pre-vulcanized treads. Generally, around 70 % of the material from the original tire can be reused in both hot and cold retreading.

From recovering reclaimed rubber to the fully integrated ContiLifeCycle plant

Continental plant in Seelze in the Hanover region

Continental plant in Seelze in the Hanover region

© Continental

The origins of Continental's tire retreading activities can be found in Hanover. Tires could already be retreaded at the Continental plant in Hannover-Vahrenwald more than 120 years ago. In 1903, the company also bought a factory building in Seelze in the Hanover region and set up a plant on the site for reclaiming, i.e. processing and recycling old rubber. Even back then, nine to 13 t of used rubber were processed every day. That is equivalent to the average weight of around eight cars. Continental was already laying the foundations for circular and sustainable business back then.

Continental set another important milestone in the retreading of truck tires in 2013 when it opened the ContiLifeCycle plant in the Stöcken district of Hanover. The distinctive feature of this plant is its combination of a retreading and a recycling plant. With an integrated approach consisting of hot retreading for truck and bus tires as well as a rubber recycling system developed specifically for the ContiLifeCycle plant, the company has been actively promoting the sustainable use of raw materials, water and energy for a decade. Since 2013, around 900 000 truck and bus tires have been given an extended service life through retreading at the plant in Hanover-Stöcken.

Added value for fleet customers

Tansu Isik, Head of Region South, Channels Fleet and OE Trailer for Continental Tires EMEA

Tansu Isik, Head of Region South, Channels Fleet and OE Trailer for Continental Tires EMEA

© Continental

Retreaded tires also contribute to Continental's LODC-concept, which is specially designed for vehicle fleets. "LODC stands for Lowest Overall Driving Costs, which is our comprehensive consultancy approach that seeks to help fleet customers to reduce their tire-related operational costs," explains Tansu Isik, Head of Region South, Channels Fleet and OE Trailer for Continental Tires EMEA. The sustainable ContiLifeCycle concept is an integral part of our LODC approach, offering fleet customers hot and cold retreaded tires, service-oriented casing management including ContiCasingAccount as well as durable and fuel-saving new tires. "With our ContiRe and ContiTread retreads, fleets can reduce their tire costs by up to 35 %, with a significantly lower environmental impact," Isik explains.

Expanding the circular economy

The retreading activities are an example of Continental's intelligent circular economy solutions. The environment benefits from retreading, as the use of valuable resources such as crude oil, natural rubber and water can be significantly reduced. In addition, retreading helps to save CO2 emissions, as it requires up to 70 % less energy compared to the production of a new tire. The fact that a large proportion of the casing can be reused contributes to the cost efficiency.

ContiLifeCycle plant for retreading truck and bus tires at Continental at the Stöcken, Hanover, site

ContiLifeCycle plant for retreading truck and bus tires at Continental at the Stöcken, Hanover, site

© Continental

Continental is working tirelessly to advance innovative technologies and sustainable products and services throughout its entire value chain, from sourcing sustainable materials to recycling end-of-life tires. The company also relies on the pyrolysis of used tires. The overall goal is to recover 60 % of the materials used in tire construction from used tires by 2050 at the latest.