GKD wins AFS New Product Award

22.04.2024With a revolutionary unit for microplastic separation, another product of the GKD Group has been honored with the AFS New Product Award. After the VOLUMETRIC and POROMETRIC mesh, the VORTEX separation unit is the third innovation from GKD to receive the US award.

Markus Knefel, Senior Manager Product Pre-Development & Development, GKD Group, accepts the AFS New Product Award at the AFS Filtcon in Houston, Texas

Markus Knefel, Senior Manager Product Pre-Development & Development, GKD Group, accepts the AFS New Product Award at the AFS Filtcon in Houston, Texas

© GKD Group

After the VOLUMETRIC mesh received the AFS New Product Award in 2016 and the POROMETRIC mesh in 2013, the new VORTEX separation unit from GKD completes the trio. Each year, the American Filtration & Separation Society (AFS) presents the award to the most significant new product contribution in the field of filtration and separation.

The vortex technology developed by GKD in collaboration with the US start-up CLEANR is based on the innovative use of vortex flows. The two companies found the inspiration for this in nature: The separation unit is based on the natural process by which manta rays and whale sharks filter their food without clogging their gills.

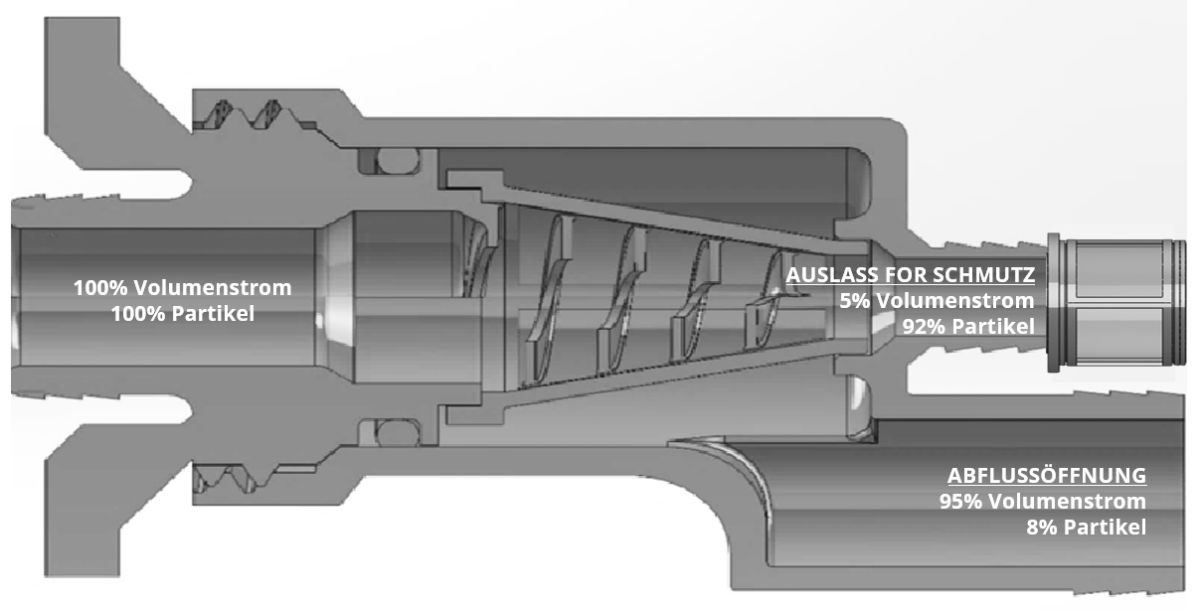

Targeted flow control: 5 % volume flow bundles 92 % of the particles for superior separation

Targeted flow control: 5 % volume flow bundles 92 % of the particles for superior separation

© GKD Group

Using biomimetics, GKD and CLEANR have succeeded in developing a unit that generates a continuous vortex thanks to its spiral geometry. The resulting centripetal force allows particles such as microplastic particles to be efficiently separated from the liquid or gaseous carrier medium.

The separation unit has already been successfully tested in washing machines. There, the product innovation removes more than 90 percent of microplastic fibers from washing machine wastewater. However, the areas of application go much further: GKD is already working on solutions ranging from drinking water filtration and air purification systems to

specific applications in the automotive industry. This makes the VORTEX separation unit a widely applicable beacon of hope in the fight against the globally growing microplastic problem.

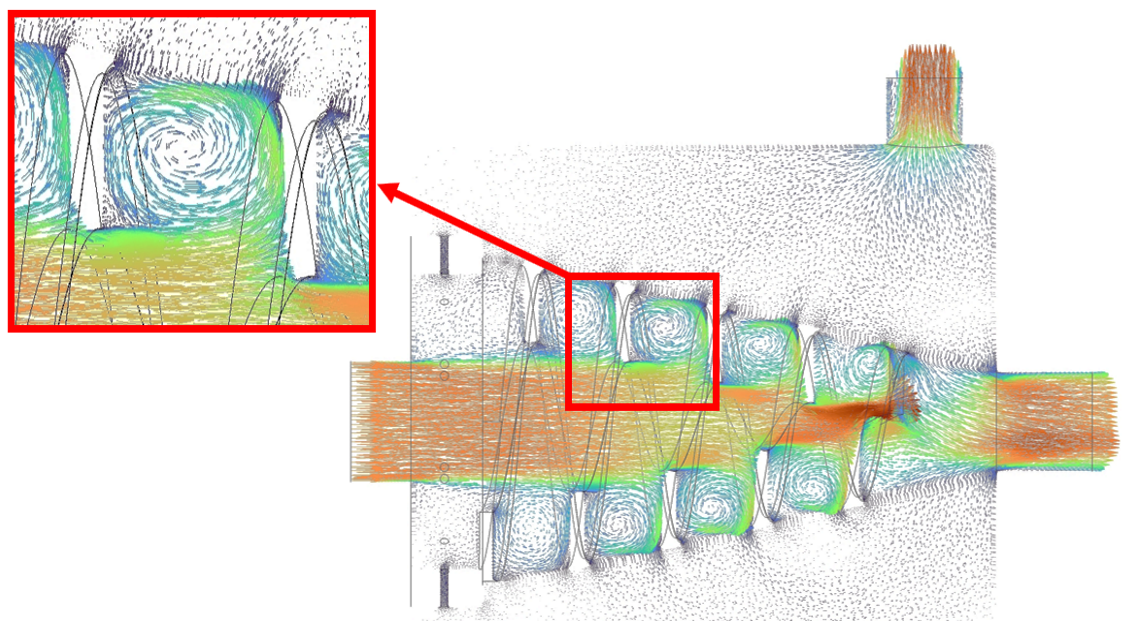

Optimization through technology: CFD simulations perfect vortex formation for maximum separation efficiency

Optimization through technology: CFD simulations perfect vortex formation for maximum separation efficiency

Compared to conventional filtration technologies such as dead-end and cross-flow, the VORTEX separation unit offers a significantly longer service life and demonstrably up to 300 percent higher particle filtration efficiency. It also minimizes or eliminates the need for additional fluid pumps and avoids the frequent maintenance of conventional systems through the innovative self-cleaning principle of vortex flow. In addition, the unit can also be integrated into existing filtration systems thanks to its modular design.

"I am very proud of this award and am delighted that we at GKD have once again succeeded in proving that innovative solutions in the field of filtration and separation can help to reduce the burden on nature," emphasizes Markus Knefel, Senior Manager Product Pre-Development & Development at GKD. "GKD's vortex technology is already being used successfully in the filtration of microplastics from washing machine wastewater. The technology has the potential to take filtration performance to a new level in other areas of application too."